With the continuous development of technology, the world of 3D printing has improved significantly in recent years. One of the most exciting developments is the introduction of 3D dual extruder technology. This innovative feature opens new possibilities for creators, entrepreneurs and industries to easily make more complex and complex designs.

For those who may not be familiar with it, a 3D dual-extruder is a 3D printing technology that uses two extruders to print using different materials at the same time. This allows the creation of objects with multiple colors, textures, and properties, while traditional single disconnector 3D printing was previously impossible. The benefits of 3D dual extruder technology are numerous and soon become a game changer in the world of rapid prototyping.

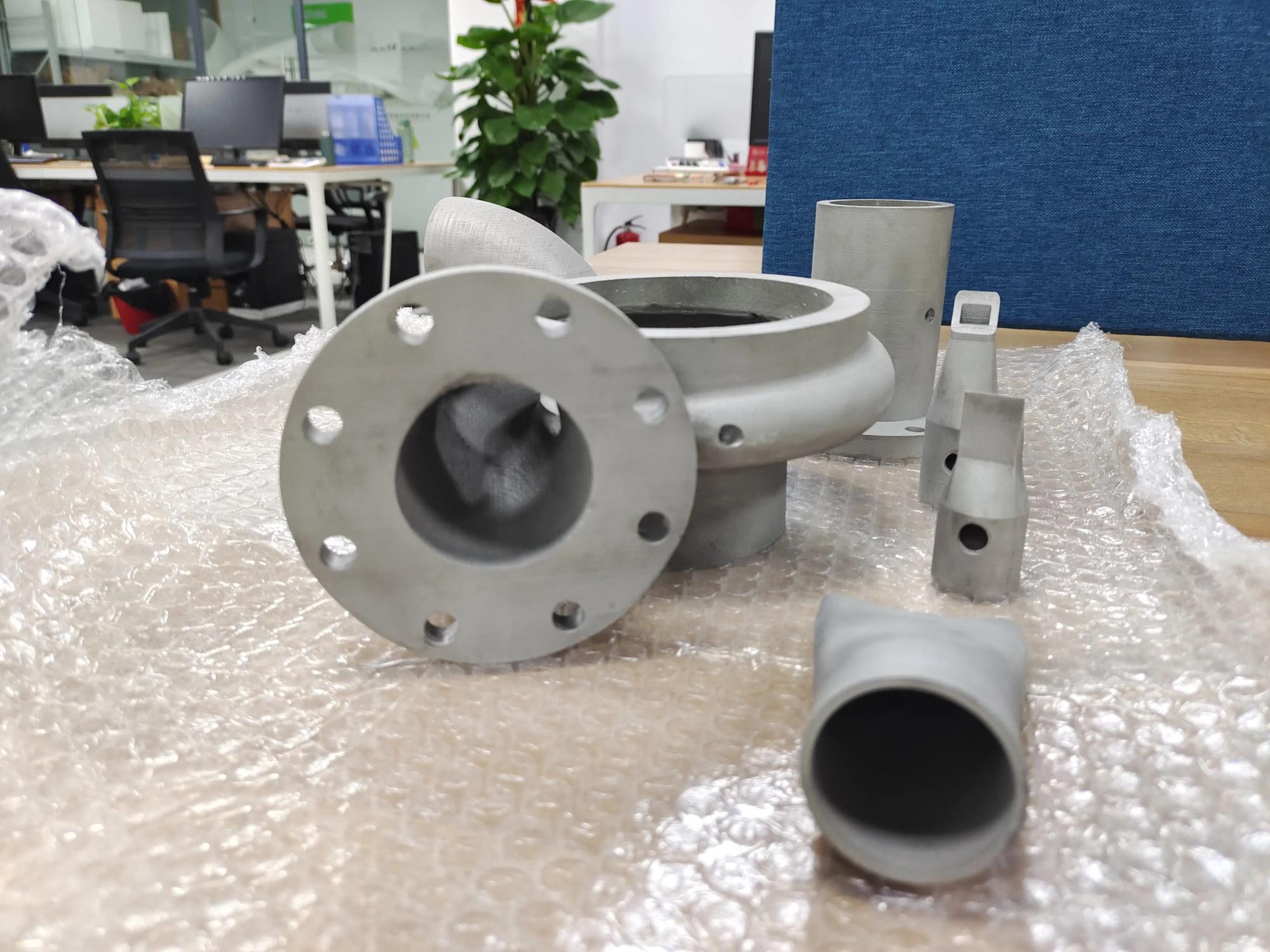

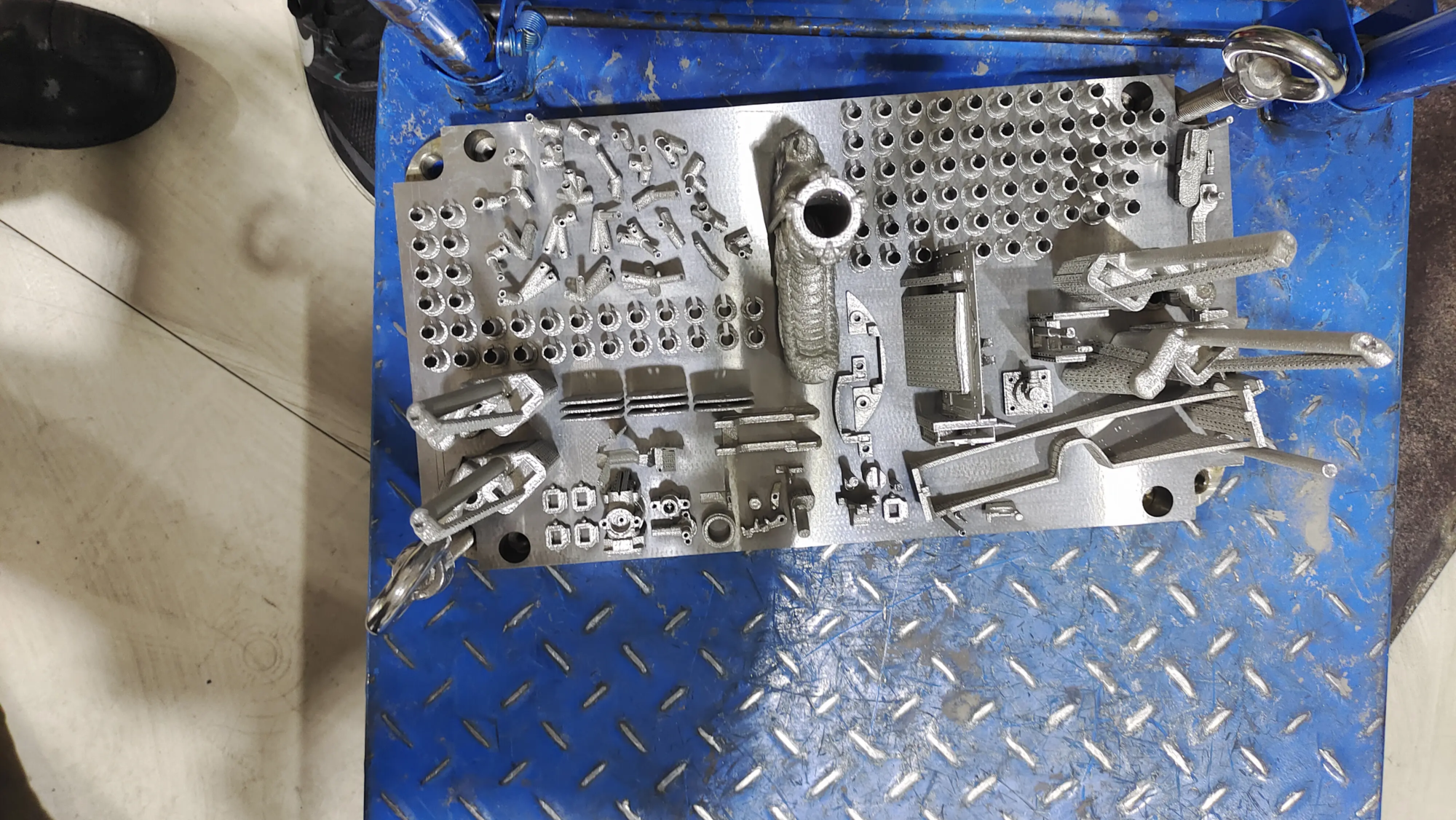

One of the most important advantages of 3D dual extruder technology is its ability to produce complex geometric shapes and designs. With two extruders, creators can print in different materials such as plastic, metal and ceramics to produce objects with different characteristics. For example, product designers can create prototypes of smartphone boxes with rigid shells and soft, flexible lined lines, all in a single print job. Traditional 3D printing methods have not been able to achieve this level of complexity before.

Another important benefit of 3D dual extruder technology is its ability to reduce production time and cost. By printing with both materials simultaneously, creators can generate complex objects in the time spent in traditional methods. This not only saves time, but also reduces production costs, making it an attractive choice for businesses and entrepreneurs who want to bring their products to the market quickly and effectively.

In addition to its technological advantages, 3D dual extruder technology has developed new creative possibilities for artists, designers and manufacturers. With the ability to print a variety of materials and colors, creators can produce complex and complex designs that were previously unavailable. This has led to a wave of new innovations in areas such as product design, architecture and even fashion.

At the professional rapid prototyping manufacturer Greatlight, we have witnessed first-hand the benefits of 3D dual extruder technology. With our advanced SLM 3D printers and production technology, we can easily produce complex metal parts, and our one-stop post-processing and finishing service ensures that each product meets the highest quality standards. Whether you want to produce prototypes or products that are ready to be produced, our team of experts can help you realize your vision.

In short, 3D dual extruder technology revolutionized the world of 3D printing, providing unparalleled flexibility, complexity and creativity. The technology has the ability to print in a variety of materials and colors, opening up new possibilities for both industry and individuals. With the continuous development of technology, we can expect to see more innovative applications and uses for 3D dual extruder printing.

FAQ:

Q: What is 3D dual extruder technology?

A: 3D dual extruder technology is a type of 3D printing, which uses two extruders to print with different materials at the same time.

Q: What are the benefits of 3D dual extruder technology?

A: The benefits of 3D dual extruder technology include the ability to produce complex geometric shapes and designs, reduce production time and cost, and open up new creative possibilities.

Q: What types of materials can 3D dual extruder technology print?

A: The 3D dual extruder technology can be printed using a variety of materials including plastic, metal and ceramics.

Q: Is 3D dual extruder technology suitable for production-ready products?

A: Yes, 3D dual extruder technology can be used to produce products ready for production, and many companies are already using this technology to bring their products to the market.

Q: How does Greatlight use 3D dual extruder technology?

A: On Greatlight, we use 3D dual extruder technology to produce complex metal parts through our advanced SLM 3D printers and production technologies. We also offer one-stop post-processing and completion services to ensure that each product meets the highest quality standards.

ISO 9001 Factory