Unlocking innovation: exploring the transformative potential of 3D printer frames

The industrial landscape is filled with innovation, and nestled within many cutting-edge facilities is an important hub, often referred to as "3D printer carriage" or "Additive Manufacturing Bay." More than just rows of machines, this dedicated space represents the cutting edge of product development and manufacturing agility. Understanding and maximizing the potential of these areas is critical for engineers, designers and businesses that are constantly pushing the boundaries of possibility. For rapidly evolving industries that require complex metal parts, partnering with a professional rapid prototyping service like GreatLight can unlock capabilities well beyond the typical in-house setup.

Beyond prototyping: The changing role of the printer bay

Traditionally, 3D printer carriages have been synonymous with rapid prototyping (RP), the rapid creation of physical models to validate designs before using expensive tooling. While this remains a core function, its role has expanded significantly:

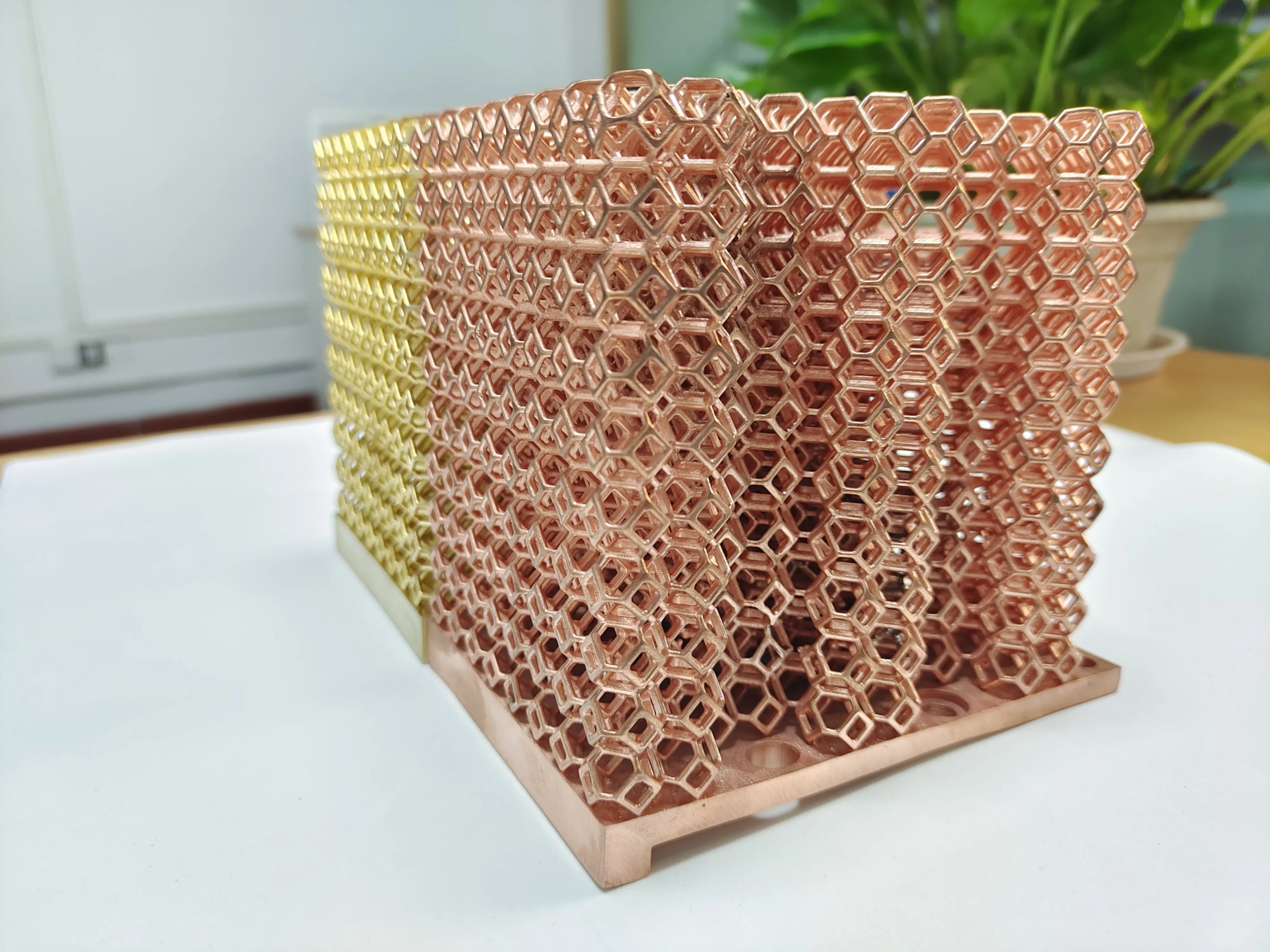

- Functional prototyping and pre-production: Gone are the days of purely aesthetic models. Modern additive processes, especially metal additive processes (such as SLM – Selective Laser Melting), produce parts that simulate the behavior of the final product under stress, heat and functional loading. Advanced racks allow complex components to be tested against real data and designs refined early in the development cycle.

- Bridge to manufacturing: The bay is the key link between design and series production. Production prototypes can be rigorously tested, manufacturing workflows validated, and even low-volume end-use parts can be manufactured directly without tool investment. this "bridge tool" The capability significantly accelerates time to market.

- Small batch and customized production: For highly specialized components, custom medical implants, complex aerospace parts, or niche market applications, 3D printer carriages yes production line. It removes the constraints of economies of scale and makes the production of customized products economically feasible.

- Tools, Jigs and Fixtures: Instead of machining expensive and time-consuming traditional tooling, job shops excel at producing optimized, lightweight, often conformally cooled production auxiliary equipment (jigs, fixtures, molds), thereby increasing the efficiency and quality of the main production shop. This is a high-value, fast-growing application.

- Spare parts and repairs on demand: Manufacturers are leveraging printer racks to maintain aging systems or produce hard-to-source spare parts on demand, reducing inventory costs and significantly reducing repair downtime. This extends the life of critical equipment and streamlines the supply chain.

Unleashing your full potential: key factors

Realizing this transformative potential will require more than just machines. It requires expertise, integration and advanced features:

- Materials Science Strength: The real power lies in the materials being worked on. Advanced carriages are capable of handling demanding metal alloys (titanium, Inconel, tool steel, aluminum alloys, cobalt-chromium alloys), solving application problems that plastic printing cannot. Suppliers like GreatLight leverage deep materials expertise to guide alloy selection and process parameter optimization for optimal performance.

- Accuracy and repeatability: For end-use parts and molds, consistent dimensional accuracy and mechanical properties cannot be ignored. Industrial-grade printers and fine-tuning processes that are tightly controlled in a professional bay environment are critical. This solidifies GreatLight’s commitment to "Customized precision machining" via additional methods.

- End-to-end workflow: The printer carriage is just the first step. Its full potential can only be realized with expert pre-processing (simulation design for additive manufacturing, support structure optimization) and comprehensive seamless integration. One-stop post-processing and finishing services (Support removal, heat treatment HIP/PIP, precision machining, polishing, anodizing, electroplating and other surface treatments). This holistic approach eliminates logistical bottlenecks and ensures parts meet final specifications.

- Scalability and flexibility: Different projects require different capabilities. Using versatile carriages equipped with various printer technologies (SLM, DMLS, possible SLS, MJF) and finishing systems, solutions can be customized according to the specific technical and economic requirements of each project, from small prototypes to medium-sized production runs.

- Speed and responsiveness: Time is a critical competitive advantage. Well-run Bay exploits the inherent speed of additive manufacturing merged Optimize workflows for material handling, build management, post-processing and logistics to deliver parts quicklyto meet the tight development schedule.

Tackle challenges with expert partners

While powerful, maximizing the bay’s potential is no easy task. Challenges include:

- High initial capital investment: Industrial metal additive manufacturing systems represent significant capital expenditures. Partnering with an established RP service allows you to leverage their investment without any capital expenditure of your own.

- Technical complexity: Mastering complex processes such as metal SLM requires specialized metallurgical and process engineering expertise. Knowledge gaps can lead to failed prints or substandard part quality.

- Post-processing burden: Metal parts often require extensive, skilled post-processing. Getting comprehensive finishing services is crucial.

- Design optimization: Taking advantage of the geometric freedom of additive manufacturing requires a move from traditional DFM principles to Design for Additive Manufacturing (DfAM). Expert guidance accelerates this learning curve.

How leading suppliers like GreatLight are increasing their capabilities

This is where a professional rapid prototyping partner transforms the technology’s potential. "concept" Printer carriage translates into tangible results:

- Advanced SLM Printers and Technology: Our advanced industrial selective laser melting printers are capable of processing a variety of aerospace-grade, medical-grade and high-performance metals with exceptional accuracy and repeatability.

- Material mastery: We have deep expertise in the material properties, process behavior and qualifications of a wide range of alloys. Most materials can be quickly customized and processedbreaking through the boundaries of standard products.

- Comprehensive one-stop service: In addition to printing, our Professional solution [of] Rapid prototyping of metal parts Covering the entire journey: expert DfAM consultation, meticulous printing, follow-up One-stop post-processing and finishing services. From stress relief and HIP/PIP processing to CNC machining, EDM, polishing and plating – we deliver parts ready to go.

- Speed and cost effectiveness: Combining optimized additive manufacturing workflows with in-house finishing allows us to offer fast turnaround times best pricesolving problems faster and cheaper than customers would typically do in-house.

- Proven expertise: As one of China’s leading prototyping experts, we have EAT (expertise, authority, credibility) Google Values. Our focus is on delivering solutions that are precisely tailored to your technical specifications and project goals.

in conclusion

The modern 3D printer shop is no longer just a prototyping shop; it is the core of agile manufacturing, enabling unprecedented design freedom, accelerated innovation and cost-effective customization. Its potential ranges from proof of concept to production of complex, functional end-use parts and tooling. While getting the best internal bay up and running requires significant resources, working with a professional rapid prototyping service provider like GreatLight provides immediate access to its full capabilities.

We bring advanced SLM metal printing technology, deep material science understanding, seamless integration of essential post-processing, and a commitment to accuracy and speed. Transform your innovative ideas into reality efficiently and reliably. Customize your precision rapid prototyping parts today at the best prices! Explore the potential that GreatLight unlocks for your next breakthrough project.

FAQ (Frequently Asked Questions)

- Q: What types of metal materials can be processed with advanced SLM/3D printing?

- one: Our industrial-grade printers handle a variety of high-performance alloys, including titanium alloys (Ti6Al4V), aluminum alloys (AlSi10Mg), nickel-based superalloys (Inconel 625/718), stainless steel (316L, 17-4 PH), tool steels, cobalt-chromium alloys, and copper alloys. We provide guidance to help you choose the best material for your application in terms of strength, corrosion resistance, heat resistance,