Veterans often ask: how to adjust settings to improve printing results?

In fact, most of them don’t have perfectly fixed parameters, so how to set parameters for different models?

This time we will carefully analyze this point. It is better to teach a man to fish than to teach him to fish. We will explain the actual effect of each setting. I think after reading it you will be able to use them. Settings independently to make the printed model more perfect.

1. Height from the ground

For a model, the most direct impact on its surface print effect is the layer height. The layer height setting is between 0.1mm and 0.3mm. The smaller it is, the finer it is. At the same time, printing time also increases exponentially. The printing time of 0.1mm layer height is three times the printing time of 0.3. mm.

So how can we make a better choice in terms of precision and duration?

The first is the requirement for the surface effect of the model. If the requirement for the surface effect of the model is high, choose a small layer height, and vice versa.

The second is details. If the model has very rich subtle details and you want to show them, you should set a smaller layer height.

The last thing is whether the curvature of the horizontal plane is getting bigger and bigger. Regarding the shape of the horizontal plane curvature, especially when the horizontal plane curvature is relatively gentle, a larger ground height will produce more obvious steps and layer patterns. In this case, set a small floor height or change the placement angle. (We will explain the latter in detail in a separate article)

2. Wall thickness and bottom and top thickness

Since the width of the horizontal line is 0.4 mm, the number of walls is an integer divided by the wall thickness by 0.4. For example, 1.2 has 3 layers of walls and 1.4 is always 3 layers. Likewise, the thickness of the bottom and top is related to the height of the floor. The outermost layer is the outer wall and the remaining layers are the inner wall.

As shown in the figure below, when printing the details, the outer wall shown in red is responsible for restoring the details and the inner wall shown in green is responsible for forming the shell structure.

If this is not necessary, simply choose 1.2mm or 0.8mm. Single-layer wall thickness reduces the strength of the model shell and will also cause fill lines to appear on bevels, etc., affecting the surface effect of the model. If the wall thickness is too thick, it will extend the printing time. and consumption of consumables.

The left side has a wall thickness of 1.2mm and the right side has a wall thickness of 0.4mm.

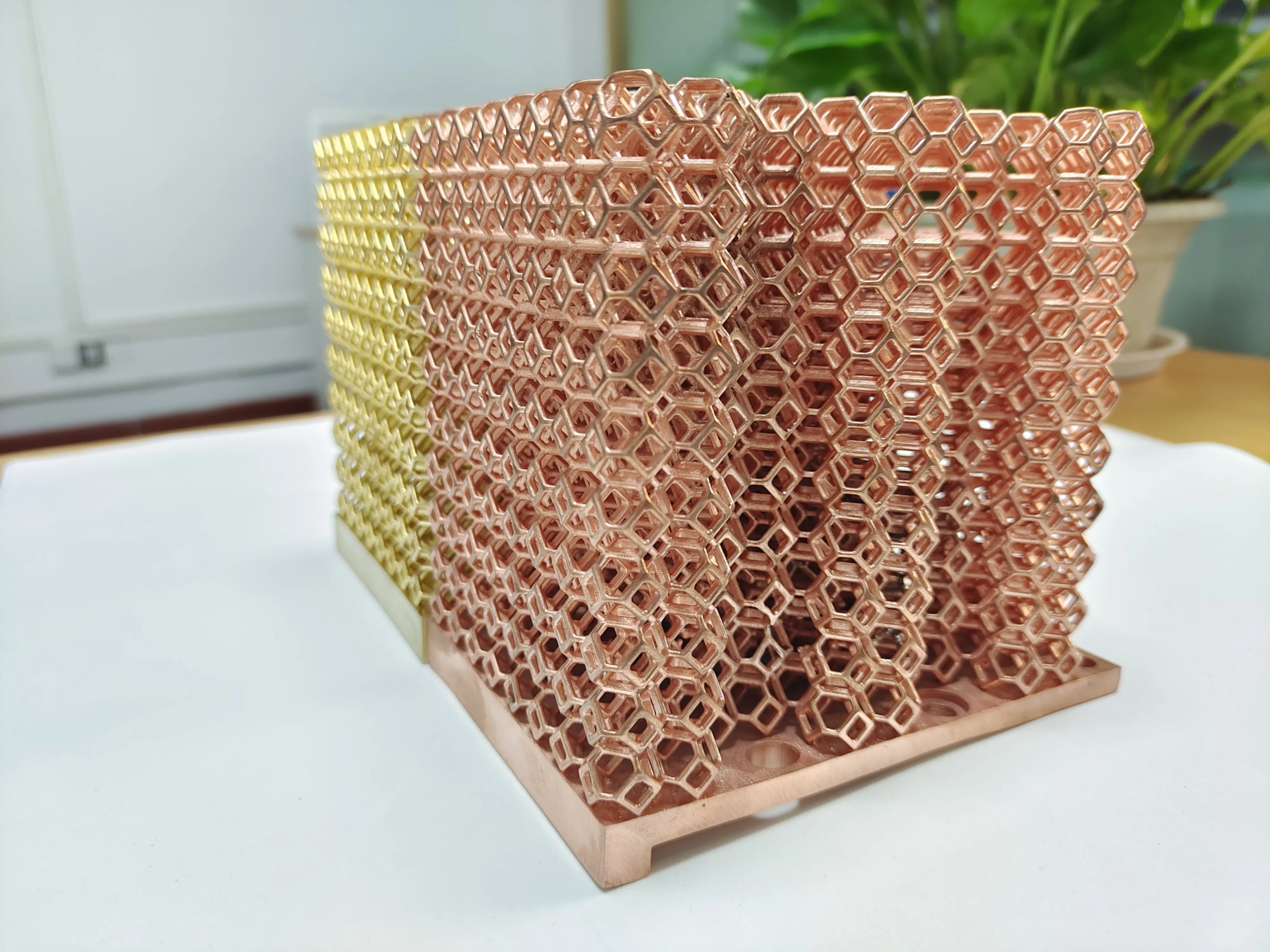

3. Filling

The primary function of the infill is to serve as structural support. When the infill is too small or even unfilled, the larger the model, the easier it is to “turn over” and become a ball of silk when printing the shell. But at the same time, if the filling is too high, reaching 80% or even 100%, the large surface of the model will be concave due to cold shrinkage of consumables. This situation is particularly evident when using materials with high shrinkage. rates such as ABS.

Another thing to note is that the fill density in JGcreat is an absolute density, that is, even if the model is enlarged or reduced, the grid size and the distance between grid lines will remain unchanged. What this gives us is that if you are printing a smaller model and want better strength, you need to set a larger infill density. When printing large models, there is no need to increase density due to concerns about insufficient model strength.

Both images above use 20% infill. When the model scale is different, the grid has the same size.

1. Printing temperature

This is the temperature to which the nozzle is heated. When purchasing consumables, you can see the recommended temperature range on the consumables and adjust the nozzle temperature according to the recommendations. The recommended temperature for high purity PLA is 200-210°C. Specialty PLA generally requires a higher temperature than regular PLA because the additives generally have a higher melting point than PLA. For PLA consumables that are wet, old and contain a lot of impurities, the temperature should be slightly increased.

ABS is an amorphous plastic and PLA is a crystalline plastic. That is, when ABS is continuously heated, the heated area softens as a whole and then becomes fluid. The PLA will be like an ice cube. The outer layer of the heated area will melt into a fluid state first, and then the inner layer will continue to melt. This means that when the temperature is insufficient, ABS can still be extruded in insufficient quantity, while PLA will not be discharged. When this situation persists, PLA liquid may leak and cause clogging or external leakage, which is therefore necessary. to observe the material discharge situation and select a good temperature before printing.

PLA will start to bubble when it exceeds 220 degrees. The higher the temperature, the more likely this phenomenon will occur.

The temperature deformation curve of plastics, ABS is similar to ①, PLA is similar to ②

2. Platform temperature

As shown in the curve above, PLA will be in a glassy state when heated to low temperatures. Heating can make PLA adhere to the platform to achieve a stable effect. When it reaches around 70 degrees, the edges of the printed model will have high vitreous elasticity (i.e. flexibility), which will reduce the stability of the model. The recommended temperature is between 50 and 60 degrees.

The temperature of the platform comes from the heat source of the heating block located under the platform and the thermal conduction of the aluminum substrate having good thermal conductivity. Therefore, the actual heating temperature at the center of the platform will be lower than the displayed temperature. When the external environment is cold, the platform temperature should be increased.

The above is a detailed explanation of the parameters related to surface quality and temperature. Understanding the principles and performance behind them can help us make better adjustments. In the next article, speed, support, platform membership, etc. will be analyzed.