From product design to factory manufacturing to multi-dimensional sales presentation integrating online and offline, Universe Electric has rapidly emerged in the industry, not only connecting consumers with green travel needs, but also promoting the innovative development of electric-assisted bicycles in China. industry. In particular, the VAPOR series they developed is known as “the world’s lightest mid-motor electric bicycle”. The entire vehicle weighs only 11 to 13 kilograms, pushing the combination of technology and design to a new level.

In the product development process, rapid iteration of prototyping is crucial for Universe Electric. However, traditional CNC machining processes often encounter problems with long cycle times and complex communication. Usually, the entire process of developing a prototype and verifying a product, from outsourcing digital models, requirements communication, supplier planning, on-machine production and express logistics, usually takes a week, even in the Yangtze River Delta region where the supply chain is relatively developed.

For Universe Electric, each design project typically requires the production of around 10 prototypes in a single batch; Once prototype verification is completed, another batch of approximately 10 working parts should be produced for testing. Both sets of parts combined will take at least two weeks, seriously limiting the speed of design iteration and product launch.

In order to face these challenges, Universe Electric has introduced Raise3D Pro3 Plus and E2CF 3D printerthese two devices revolutionize the traditional development process. Through Pro3 Plus and E2CF, the R&D team can flexibly choose different materials to meet the production needs of each stage.

During the prototyping phase, the team typically uses low-cost, high-speed printing materials, such as PLA or PETG, to quickly complete part manufacturing with a 15% infill rate. In this way, the material cost of each component is only a dozen yuan, which greatly reduces development costs.

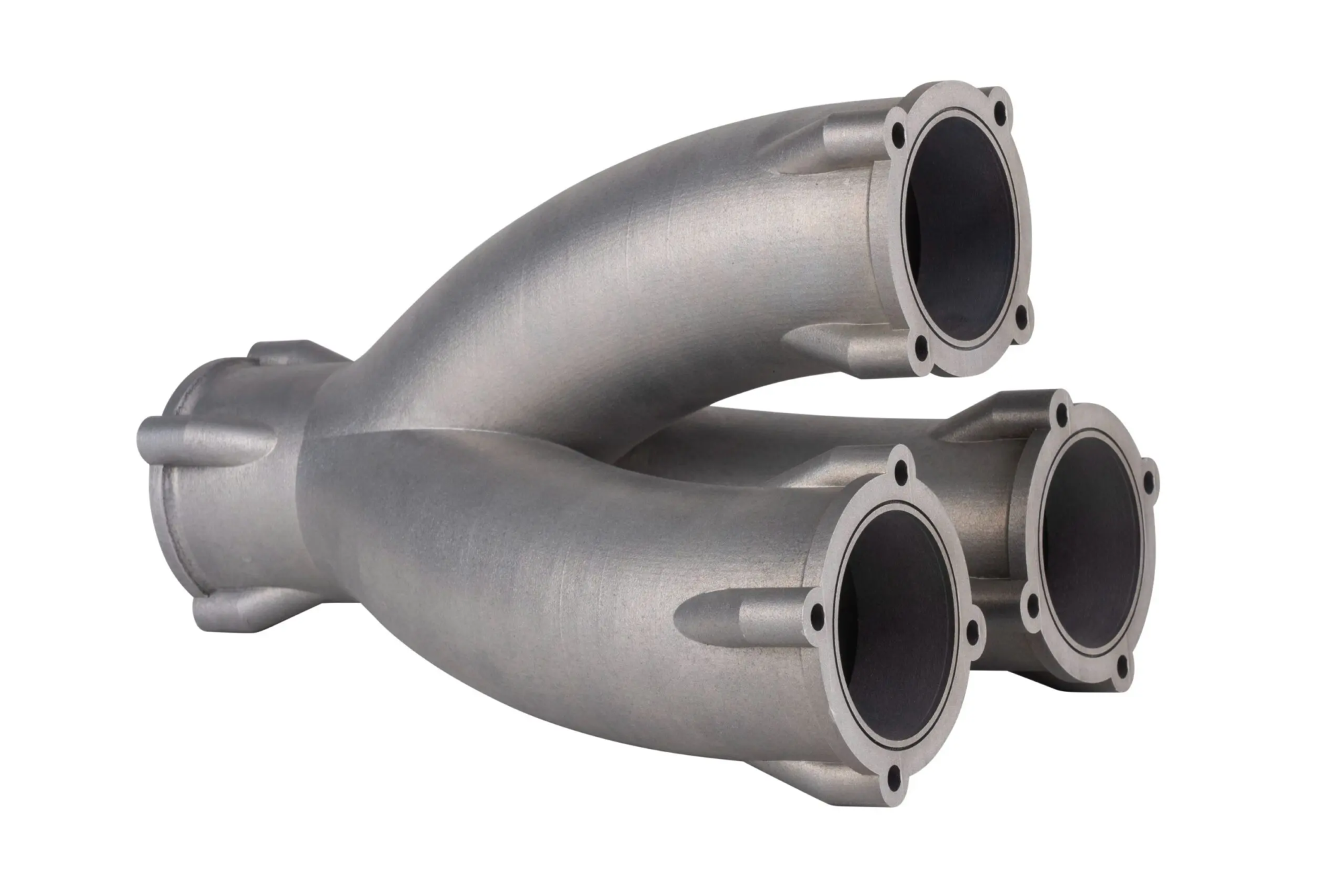

For the subsequent manufacture of the functional parts, the high-performance nylon material Industrial PPA-CF is used for printing.. The material contains 15% carbon fiber and is a high-strength modified polyamide nylon, very suitable for actual vehicle installation and testing.

This plan makes the universe electricThe traditional cycle of CNC machining two batches of parts, which takes 14 days, is reduced to just 20 hours.. Additionally, the flexibility of 3D printing not only greatly reduces outsourcing processing and communication costs, but also allows the R&D team to adjust delivery times and update parts in real time. depending on progress,Significantly improved R&D efficiency and product iteration speed。

The R&D team of Universe Electric sighed: “Raise3D’s 3D printing technology is not only a tool, but also a new way of thinking about design. It allows us to try more boldly and achieve breakthroughs more quickly.

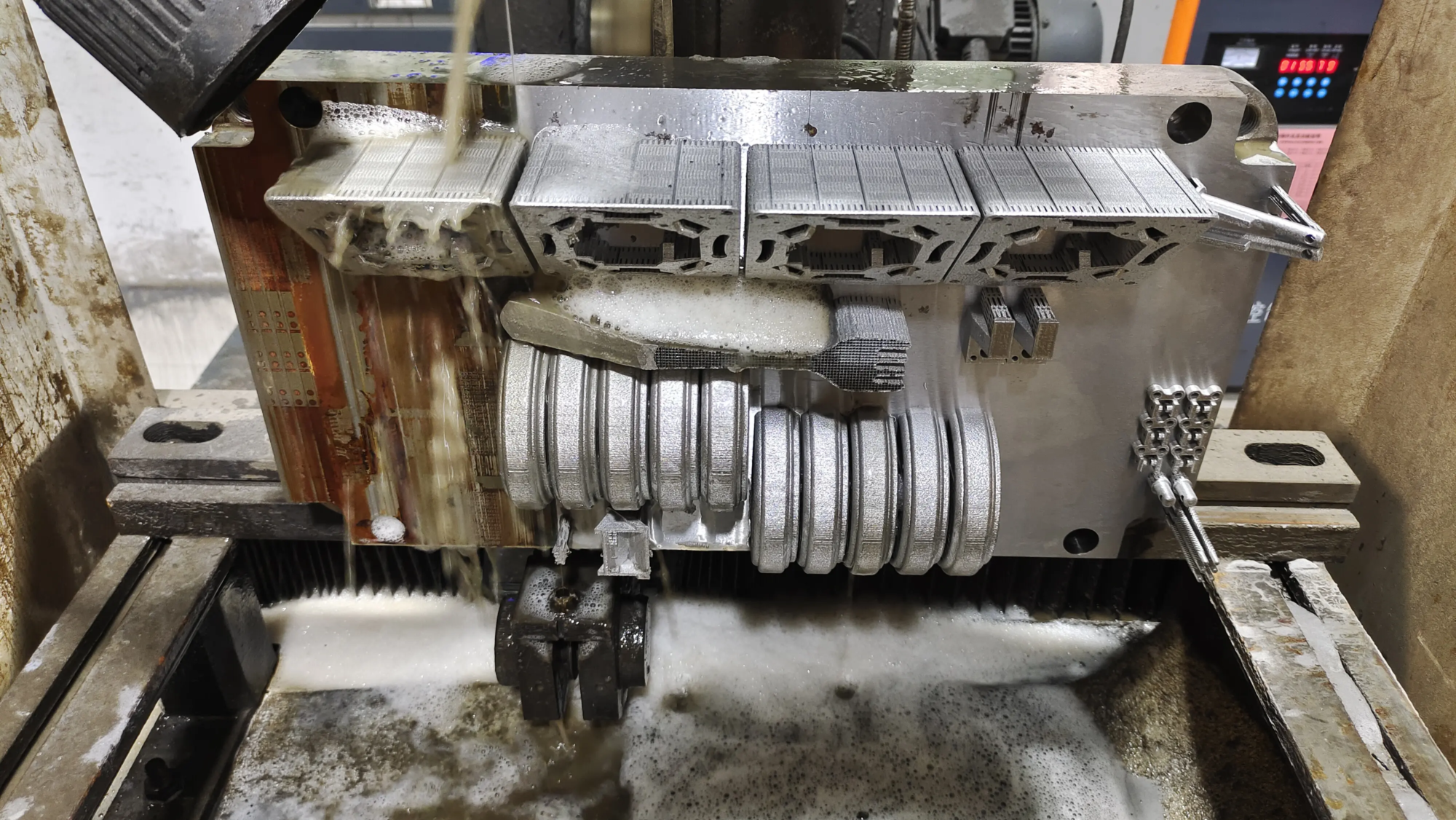

As a premium electric assist bicycle manufacturer, Universe Electric’s production process covers the three essential links of vehicle design, frame production and vehicle assembly. In these processes, the quality and efficiency of tooling directly affects the precision and production rate of the entire vehicle. However, the traditional tooling and fixture manufacturing process often faces complex process issues and long cycle times, which have become a major bottleneck limiting production efficiency.

To overcome this problem, Universe Electric chose the Raise3D E2CF 3D printer to focus on rapid manufacturing of fixtures and tooling. This deviceSupports a variety of high-performance composite materialscostssuch as carbon fiber reinforced nylon (PA CF), which is not only durable and high strength, but also capable of meeting the high precision requirements of complex fixtures. With E2CF,The production cycle of luminaires is shortened from a traditional week to 20 hours and efficiency is increased by more than 80%。

In addition, Raise3D ideaMaker slicing software and flexible printing base plate significantly optimize the printing process, making model disassembly more convenient.The printing process is more intelligent and automated. This flexible and efficient solution not only takes Universe Electric to a new level of production efficiency, but also provides reliable technical support to meet users’ various customization needs.

The cooperation between Universe Electric and Raise3D not only demonstrates the strong potential of 3D printing technology in rapid prototyping and flexible manufacturing, but also opens the door for innovation in the e-bike industry. From prototype development to tooling and fixture manufacturing, 3D printing, with its high efficiency, flexibility and low cost, provides essential technical support for Universe Electric’s rapid growth.

In the future, as 3D printing technology continues to develop in areas such as breakthroughs in high-performance materials and large-scale component printing, Universe Electric will continue to work with Raise3D to explore more possibilities.

The R&D team of Universe Electric frankly said: “3D printing is like our “invisible engine”, providing every vehicle with unlimited possibilities from design to production. It is not only an evolution in technology, but also an innovation in the eco-driving lifestyle.

*Some photos come from @CosmosE-BIKE