|

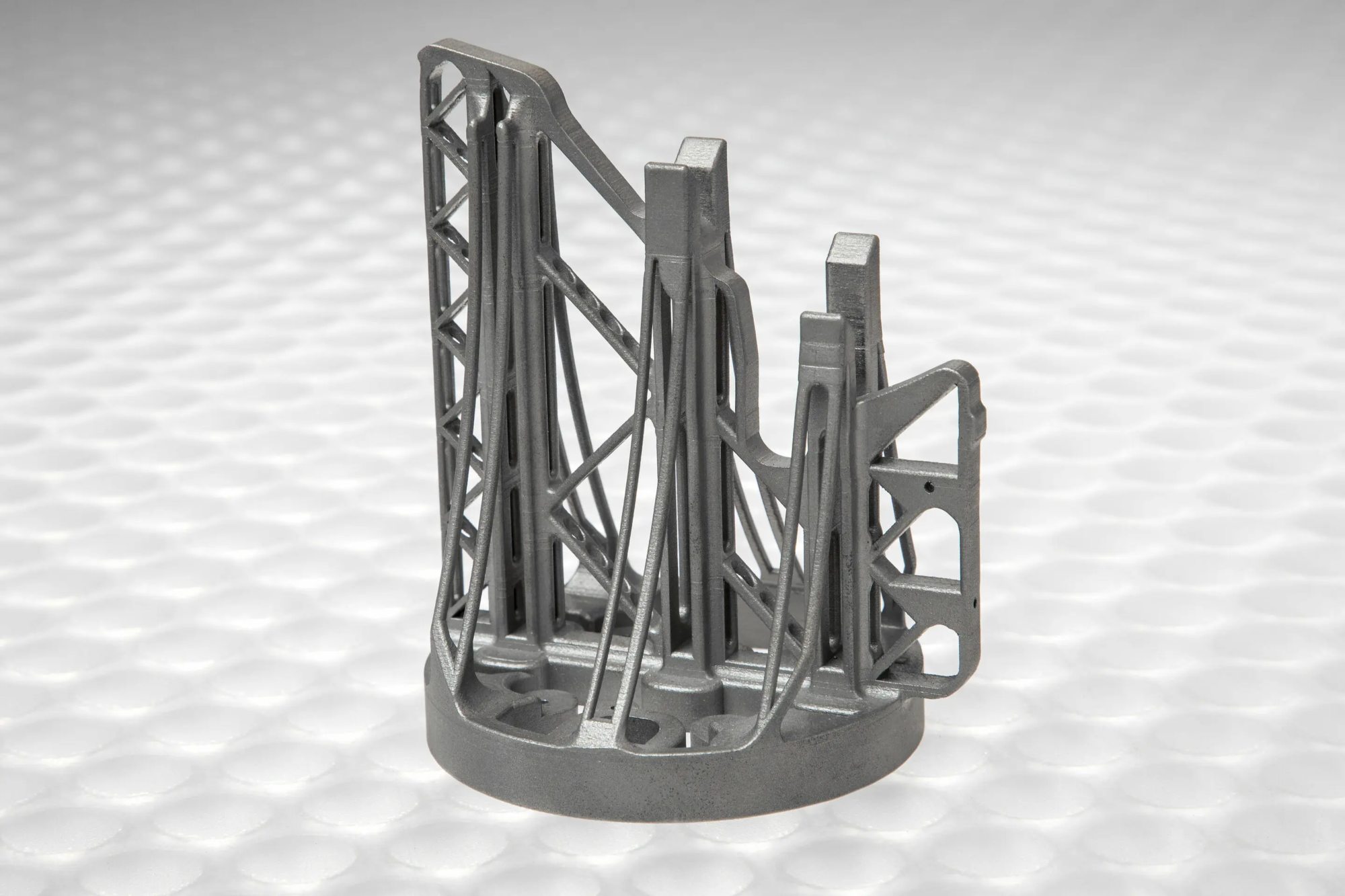

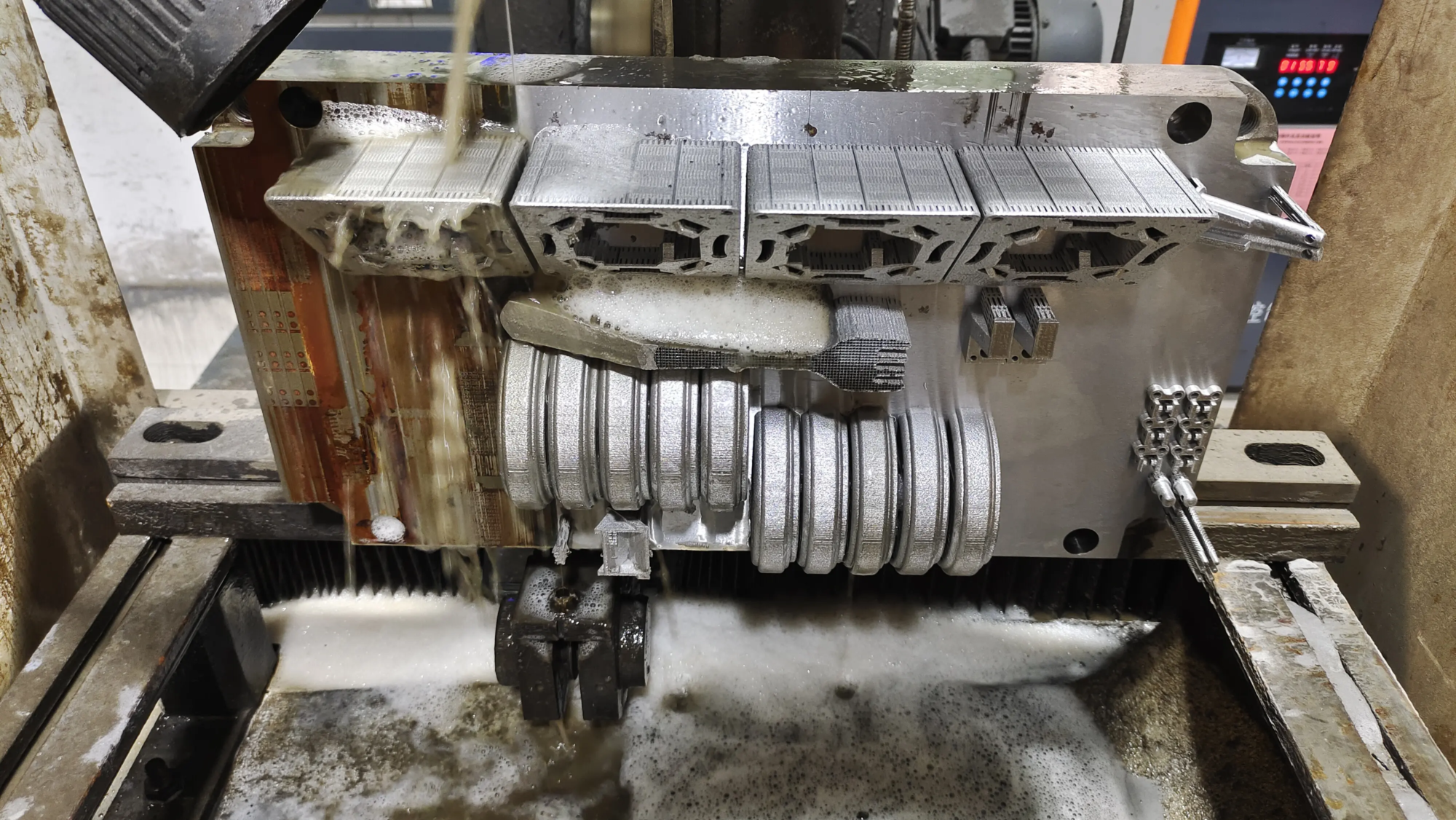

Introduction:Direct sound printing (DSP) is an alternative additive manufacturing process driven by sonochemical polymerization that has traditionally been limited to a single acoustic intervention area, resulting in a voxel-by-voxel printing approach. To overcome this limitation, researchers at Concordia University introduced holographic direct sound printing (HDSP) technology. In this technology, acoustic holograms are used to store cross-sectional images of parts, and the sound waves are structured to induce cavitation bubbles in specific areas and achieve aggregation in the desired areas, thus producing a print without hierarchical structure. On October 10, 2024, the Resource Library learned that researchers at Concordia University have successfully developed a new printing method, holographic direct sound printing (HDSP), which is believed to be faster than standard printing methods existing 3D models and would allow more to be created. complex objects. Relevant research articles have been published in the journal Nature Communications. The key technology of HDSP is acoustic hologram, a technology capable of precisely controlling the sound field. Compared to traditional phased array transducers (PATs), acoustic holograms can not only create complex sound fields at lower cost, but also provide a higher degree of freedom. In many fields such as medical imaging, cell structuring and particle assembly, acoustic holography technology has demonstrated its strong application potential. By combining acoustic holography technology with additive manufacturing, HDSP becomes a revolutionary new process capable of reducing printing time and saving energy. Figure 1: HDSP concept and printed objects.a diagram of the HDSP process, where the printed part is located on a platform mounted on the robot end effector, showing the end effector coordinate system (ECS) and the degrees of translation (xyz) and rotation (ωx, ωy, ωz) freedom. b Detailed view of the printed area producing cavitation bubbles near the target pressure image. c Printed “DSP” letters, printed parameters: P = 20 W, f 0 = 2.28 MHz, DC = 35%, and their corresponding simulated pressure mode p, normalized to the maximum pressure PMAX. d printed maple leaf, printing parameters: P = 25 W, OD = 50 mm, f 0 = 2.28 MHz, DC = 30%. e A fully transparent print wall extruded/printed axially by f feeding along the +z axis, print parameters: P = 6 W, OD = 25 mm, f 0 = 2.24 MHz, DC = 20 %. f Transparent spiral printed by translation and rotation movement of the multi-axis HDSP platform. g Self-supporting U-shaped object printed with a robot trajectory calculated using the same printing conditions as (e). OD, P, f 0 and DC are the transducer aperture size, acoustic power, acoustic center frequency and duty cycle, respectively. The core technology of HDSP – Direct Sound Printing (DSP), which is an additive manufacturing process driven by sonochemical polymerization, completes printing through the polymerization reaction of acoustic cavitation bubbles in the print medium. The phenomenon of cavitation means that bubbles generated by sound waves expand at low pressure and collapse violently at high pressure. The extremely high temperature and pressure generated by collapsing bubbles can instantly trigger chemical reactions and achieve polymerization of materials. Unlike traditional 3D printing processes that rely on light or thermal energy to activate chemical reactions, DSP generates chemical reactions via sound waves, becoming a new way to process materials. Similar to traditional additive manufacturing processes such as stereolithography (SLA), early DSPs can only print one voxel at a time and printing speed is limited. To solve this problem, researchers introduced holographic direct sound printing (HDSP). Using acoustic holography technology, HDSP can cure simultaneously across the entire cross-section, instead of just point-by-point printing, which greatly improves printing efficiency. Acoustic holograms are sound pressure models that store cross-sectional information about printed parts. When ultrasonic waves pass through these holograms, they induce cavitation bubbles in targeted areas of the material and complete the polymerization reaction. This method not only speeds up the printing process but also allows the creation of complex, non-hierarchical structures. Figure 2:SCL experiments use holograms to demonstrate the patterning of chemical reactions. The SCL setup included a DSLR camera to capture a top view of the luminol solution surface. b1 – Luminol lighting model captured by e1. b2 – The corresponding theoretical sound pressure diagram on the target plane e2. The acoustic parameters used in (b) are OD = 25 mm, f 0 = 2.24 MHz, DC = 100%, P = 15 W, and the acoustic parameters used in (c) are OD = 35 mm, f 0 = 1.86 MHz. , DC = 100%, P = 20 W, the acoustic parameters used in (d, e) are OD = 50 mm, f 0 = 2.28 MHz, CC = 100%, P = 25 W.

HDSP has an order of magnitude speed improvement over traditional DSP. Compared with the currently widely used optical additive manufacturing technology, HDSP is more suitable for materials that are difficult to process with light or heat, such as thermosetting materials. Additionally, the “Remote Distance Printing” (RDP) concept offered by HDSP even allows non-invasive printing through obstacles such as optically opaque materials or human tissues. Figure 3: A closer look at the HDSP printing process using high-speed imaging. a Side view of the observation setup, including the high-speed camera used to capture the HDSP printing process. b and c are the normalized measured pressure maps of the designed two- and three-point pressure images respectively. The gap between two points is 3 mm in (b) and 4 mm in (c). d Taking high-speed imaging of two dots printed using the HDSP process during 1 s of sonication. e High-speed imaging of a three-point print during 1-second sonication. In all cases, the platform (image plane) was designed to be 20 mm away from the transducer, with printing parameters: OD = 25 mm, P = 5 W, f 0 = 2.24 MHz, DC = 50%. The researchers pointed out that the technological progress of HDSP not only promotes the development of additive manufacturing, but also opens a new research field for ultrasonic 3D printing. HDSP has great potential in applications such as medicine, industrial processing and environmental management. For example, in the future, this technology could be used to achieve non-invasive printing of medical devices inside the body, thereby bringing a revolutionary advancement in the medical field. Figure 4: Special applications of HDSP. a Simulates the pressure field of a multi-objective image plane, creating multiple points at once. b Print individual spots at a time on a multi-layer platform using a single acoustic hologram. c Print on non-transparent media for remote printing (RDP) applications. d Schematic of the idea of invasive printing in living organisms via the RDP concept. Enlarged view detailing the porcine tissue layers used in the RDP experiments. e Twisted helix printed on the barrier comprising the porcine tissue shown in (d). Print Settings: OD=25mm, P=8W, f0=2.24MHz, DC=50% fA maple leaf printed on a non-transparent material is another example of RDP. Print Settings: OD=50mm, P=25W, f0=2.85MHz, DC=50% g Example of overprinting possibilities in HDSP, where two walls are printed on a printed hollow circular shell. The manufacturing steps are shown in Figures 1 and 2. Researchers believe HSDP has the potential to become a revolutionary technology – similar to the progress made in light-based 3D printing since the early days of stereolithography (SLA, which uses lasers to harden resin into a solid point by point) up to today’s digital light processing technology (DLP, capable of curing the entire resin layer simultaneously). Figure 5: Robot-assisted HDSP. aThe experimental setup includes a printing platform mounted on the end effector of a robotic arm and an arc printed with the corresponding pressure pattern. bAn object with an in-plane extrusion path. c A spiral-shaped object created by rotating around the z axis at variable feed while extruding in the +z direction at constant feed. The pressure model used is shown in the box. The inset shows a 3D model of the intended component. d Unsupported U-shaped part formed using calculated robot trajectories. Schematic diagram of the printing process and calculated trajectories of e–h (d). With the development of HDSP technology, the additive manufacturing industry is expected to achieve more unimaginable innovations. The emergence of this technology not only offers new solutions for fast and efficient 3D printing, but also opens up new possibilities for processing complex materials and performing remote printing. In the future, HDSP could play a key role in many fields such as medical care, aerospace and electronic products. Figure 6: Characterization of processes linked to the HDPS hologram. a Surface deviation and distribution of deviations between fabricated holograms and theoretical holograms. b Pressure models of a theoretical hologram (b left) and a fabricated scanned hologram (b right) obtained by finite element analysis. c Study of the resolution of the image and the printing by varying the OD and the f 0, by constructing a theoretical image of the mandala (c on the right) at low resolution (c on the left), OD = 25 mm, f 0 = 1.5 MHz, at high resolution (c right) Construction of a theoretical image of the mandala (center c). d, e Correlation and NMSE of the theoretical mandala image (center of c) with respect to OD and f 0. f Image plane position, target Z and its effect on correlation and NMSE. Overall, holographic direct sound printing (HDSP), as a new paradigm of acoustic additive manufacturing, marks that 3D printing technology has entered a new stage. We look forward to more practical cases on the application of HDSP technology and its new advancements in industrial and medical fields. |