The ultimate guide to enhancing your VR experience: 3D printed stand for Meta Quest 3

As virtual reality transforms entertainment and professional workflows, owning a Meta Quest 3 headset has become your gateway to an immersive experience. However, storing your headphones safely is crucial to extending their lifespan and convenience. Enter 3D printed bracket– Game-changing solutions that combine innovative design with engineering excellence. At GreatLight, we specialize in turning digital concepts into tangible precision parts and helping enthusiasts create accessories like never before. Here’s why a 3D printed stand is essential for Quest 3 owners, and how our technology can elevate the game.

Why choose custom 3D printed brackets?

Traditional retail booths often compromise on ergonomics or cannot accommodate controllers and cables. 3D printing solves this problem by:

- Hyper-personalized design: Custom sizes for your charging base, controller mount or cable routing.

- Optimization function: Integrated ventilation slots prevent overheating, rubber handles protect the lens, and modular sections organize space.

- Cost effective: Bypass retail markup – perfect for DIY enthusiasts iterating on prototypes.

Design Essentials: Design a Lasting Exhibition Stand

Creating a functional exhibition stand requires careful planning:

- structural integrity

Sturdy base prevents tipping. Stability is ensured by a hexagonal pattern or a weighted base that enables infill optimization during printing. - Cable management

USB-C cable channel eliminates tangles and enables pass-through charging. - Thermal management

Strategically placed perforations promote air circulation and prevent condensation from forming during storage. - Material selection

- Polylactic acid/nylon: Affordable, lightweight, and ideal for prototyping.

- PETG/ABS: Enhanced durability and heat resistance.

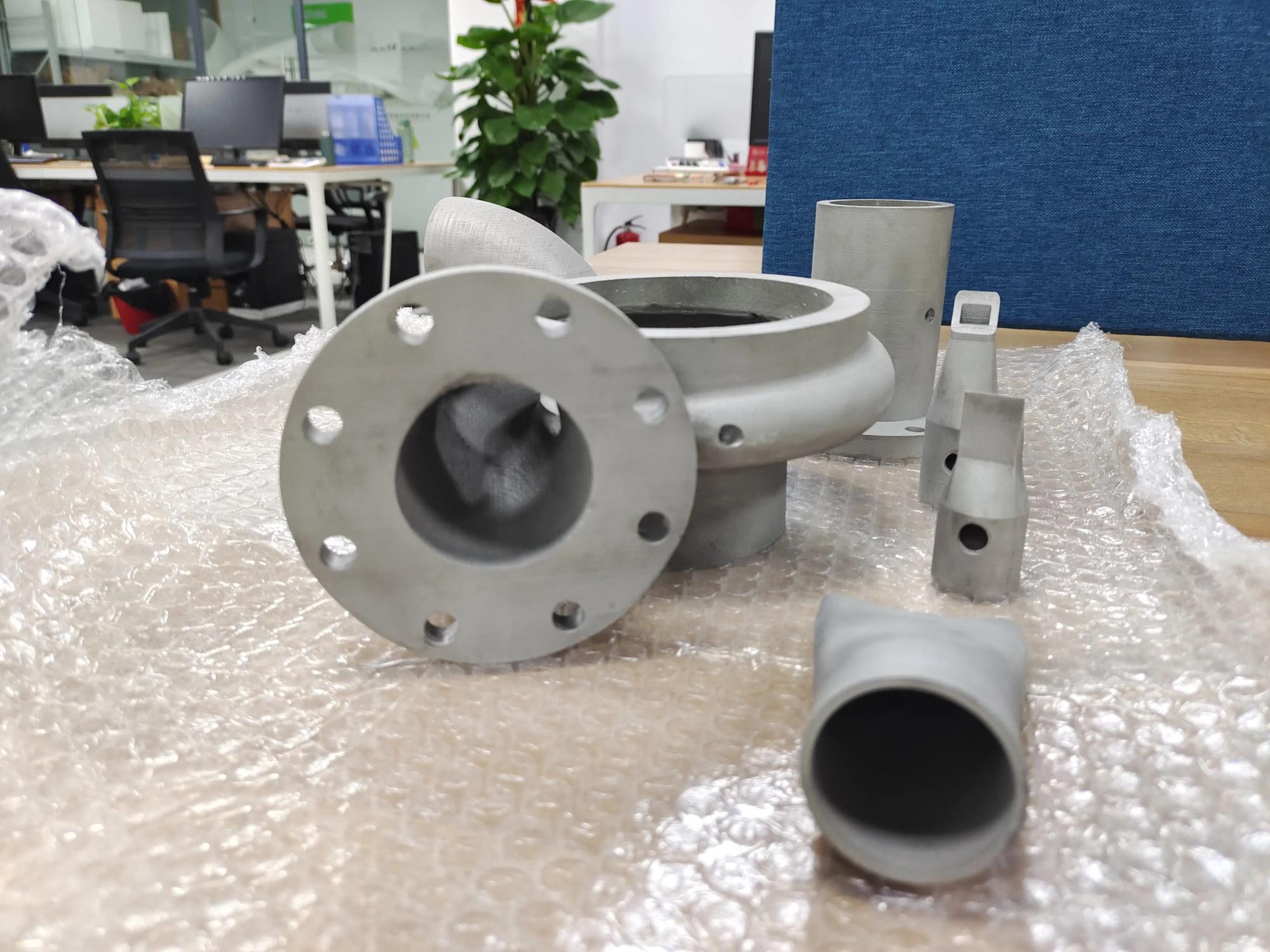

- Metal alloy (AlSi10Mg, titanium): Industrial-grade flexibility achieved through SLM printing, ideal for commercial production.

Ferrite’s Manufacturing Advantages

As a leader in rapid prototyping, GreatLight utilizes Industrial SLM (Selective Laser Melting) 3D Printer Producing exhibition stands that go beyond traditional quality:

- complex geometric shapes: Prints a mesh structure that minimizes material usage without sacrificing strength.

- Metal customization: Create corrosion-resistant aluminum brackets or titanium brackets suitable for wet environments for unparalleled longevity.

- End-to-end refinement: Our post-processing includes CNC machining to ensure dimensional accuracy, powder smooth surface treatment and protective coatings.

Why choose us to provide you with Quest 3 accessories?

GreatLight is more than a manufacturer, we are an innovation partner. Our customers benefit from:

✅ Prototype to production continuity: From concept sketches to mass production, all under one roof.

✅ Speed without compromise: Fast turnaround (as fast as 48 hours) for prototypes and end-use parts.

✅ Materials expertise: Source over 50 metal/polymer materials optimized for thermal, mechanical or aesthetic needs.

✅ Cost-effective scalability: ISO certified quality assurance brings economies of scale to SMEs and bulk orders.

in conclusion

Meta Quest 3 deserves smart storage—a stand that combines security, convenience, and style. 3D printing enables unlimited customization, while GreatLight’s SLM technology provides creators with industrial-grade precision. Whether you’re a DIY design prototyping enthusiast or brand-scale production, we can transform your vision into flawless engineering reality. Elevate your VR ecosystem today: from garage innovation to global deployment, we are your trusted rapid prototyping ally.

FAQ section

Q1: How long does it take to 3D print the Quest 3 stand?

A: For plastic prototypes, expect 5-8 hours on a desktop printer. Using GreatLight’s SLM industrial system, metal scaffolding takes 24-48 hours (including post-processing).

Question 2: Are metal brackets worth it compared to plastic brackets?

A: For commercial resale or humid climates, yes. The service life of metals such as AlSi10Mg is 5 times that of polymers without deformation. GreatLight optimizes costs through nesting (printing multiple units simultaneously) to lower per-part pricing.

Q3: Can I send my own 3D design files for manufacturing?

Answer: Of course. We accept STEP, STL or OBJ files. Our engineers review designs for manufacturability and recommend structural integrity adjustments at no charge.

Q4: What post-processing options are available?

A: From sandblasting (matte texture) to electroplating (gold/silver finish), polymer dyeing or CNC machined polish, we ensure beauty meets functionality.

Q5: How does Honglait ensure the QA of high-precision parts?

A: Each component undergoes dimensional verification, tensile testing and thermal stress simulation in compliance with ISO 9001 standards via CMM machines.

Q6: What if I need design help?

A: Our team offers free DFM (Design for Manufacturability) consultation – optimizing wall thickness, support structures, and material selection for SLM printing.

Turn your vision into reality

Ready to prototype a custom Quest 3 stand or production-quality accessory? Partner with GreatLight to take advantage of cutting-edge SLM printing, materials science and one-stop finishing. Request a quote today—a combination of imagination and aerospace-grade precision.