With the increasing demand for complex and customized metal parts, metal 3D printing has become a revolutionary technology in the manufacturing industry. Metal 3D printing, also known as additive manufacturing, can create complex and precise metal parts with unprecedented design freedom. In this comprehensive guide, we will dig into the world of metal 3D printing and explore its principles, benefits and applications.

Introduction to 3D metal printing

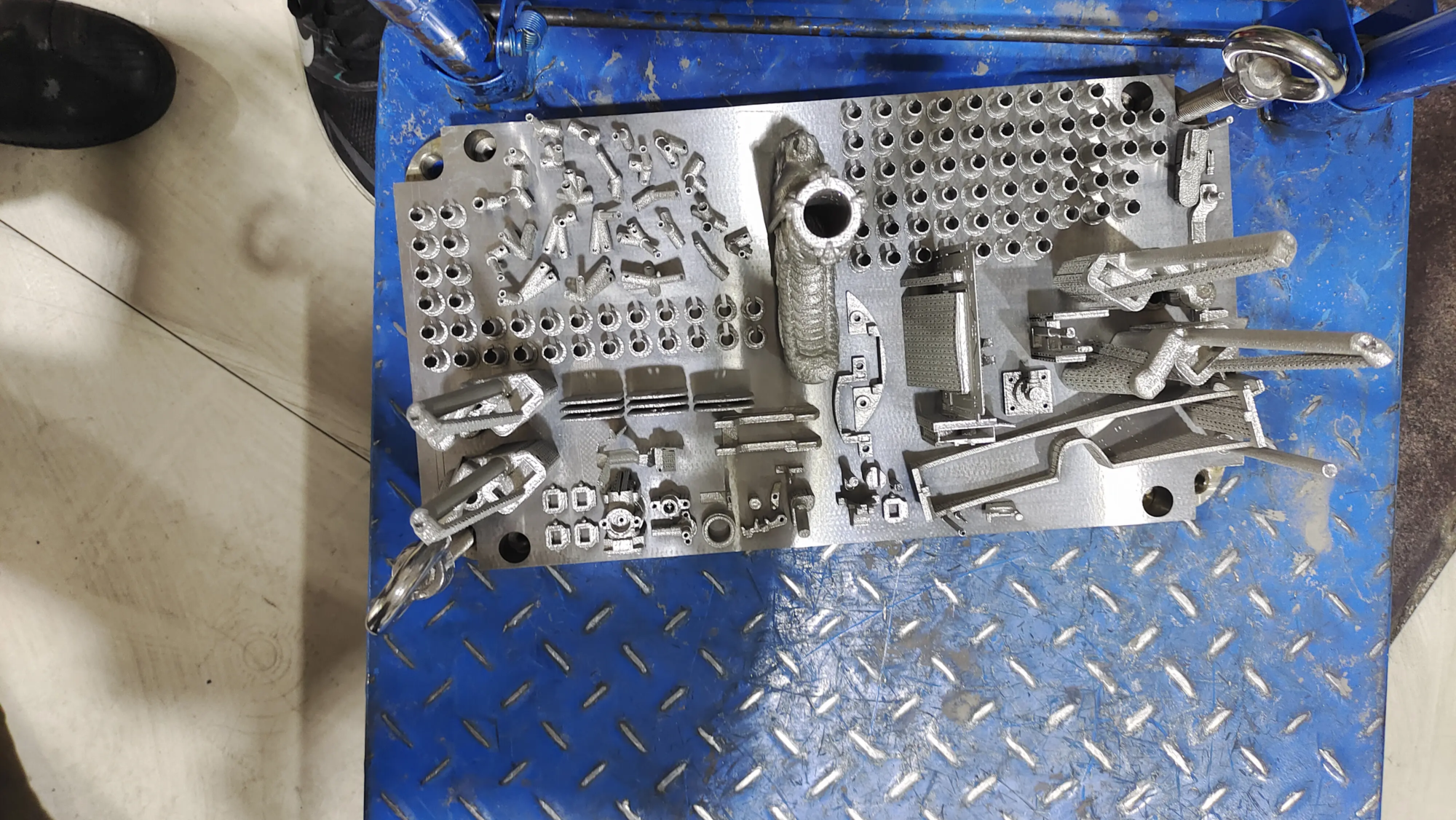

Metal 3D printing is a layer by layer manufacturing process involving the fusion of metal powder or wires to create solid parts. Advanced technologies such as selective laser melting (SLM), electron beam melting (EBM), and laser beam melting (LBM) make this process possible. These techniques make it impossible to produce complex geometric shapes, internal structures and custom parts by traditional manufacturing methods.

The benefits of metal 3D printing

Metal 3D printing provides many benefits, including:

- Increase design complexity: Metal 3D printing allows the creation of complex geometric shapes, internal structures and custom parts that cannot be produced by traditional manufacturing methods.

- Reduce material waste: Metal 3D printing is an additive process, which means adding materials only as needed, reducing waste and minimizing environmental impact.

- Improved product performance: Metal 3D printing can create parts with optimized structural characteristics such as lightweight, improved thermal management and enhanced mechanical properties.

- Faster production time: Compared to traditional manufacturing methods, metal 3D printing usually produces parts quickly in a few hours or days, while traditional manufacturing methods can take weeks or months.

Application of metal 3D printing

Metal 3D printing has a wide range of applications in various industries, including:

- aerospace: Metal 3D printing is used to produce lightweight, high-performance parts for aircraft and spacecraft.

- car: Metal 3D printing is used to produce customized parts such as engine components, transmission parts and other complex components.

- Medical: Metal 3D printing is used to produce customized implants, surgical instruments and medical equipment.

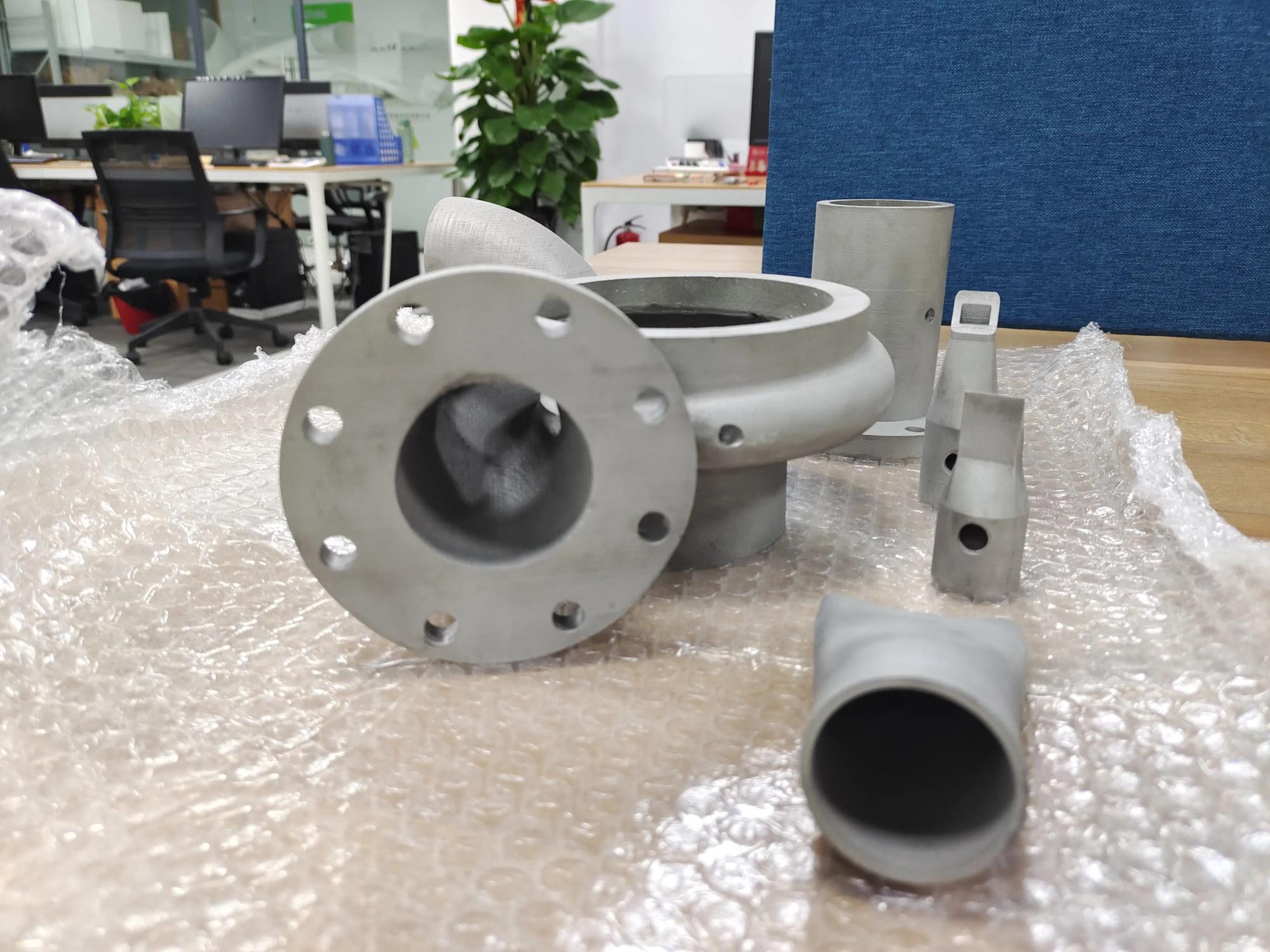

- Industrial Equipment: Metal 3D printing is used to produce complex parts such as pump components, valve components and other equipment components.

Post-processing and completion of services

While metal 3D printing can produce parts with high precision and precision, post-processing and finishing services are often required to achieve the desired surface finish, dimensional tolerance and material properties. These services include:

- Processing: CNC machining, grinding and polishing for precise dimensional tolerances and surface finishes.

- Heat treatment: Heat treatment processes such as annealing, hardening and backtempering to achieve the desired material properties.

- Surface finish: Surface finishing techniques such as coatings, paintings and electroplating to enhance corrosion resistance and aesthetic appearance.

in conclusion

Metal 3D printing is a revolutionary technology that transformed manufacturing. Its unprecedented design freedom in the production of complex and customized metal parts opens new opportunities for innovation and growth. As the demand for metal 3D printing continues to rise, it is necessary to understand the principles of the technology, the benefits and applications are crucial. Whether you are an engineer, designer or manufacturer, metal 3D printing is an exciting and rapidly growing field that is worth exploring.

FAQ

Q: What is metal 3D printing?

A: Metal 3D printing, also known as additive manufacturing, is a layer by layer manufacturing process involving the fusion of metal powder or wires to create solid parts.

Q: What are the benefits of metal 3D printing?

A: Metal 3D printing provides many benefits, including increased design complexity, reduced material waste, improved product performance and faster production time.

Q: What is the application of metal 3D printing?

A: Metal 3D printing has a wide range of applications in various industries including aerospace, automotive, medical and industrial equipment.

Q: Do I need post-processing and completion services for metal 3D printed parts?

A: Yes, post-processing and completion services are often required to achieve the required surface surface, dimensional tolerance and material properties.

Q: How to start using metal 3D printing?

A: You can contact Metal 3D Printing by contacting professional rapid prototyping manufacturers such as Greatlight, who can provide one-stop post-processing and completion services and customize your precision rapid prototyping parts at the best prices.