Leverage power supply: Organize Milwaukee M18 and M12 batteries with custom 3D printing solutions

In the world of power tools, Milwaukee’s M18 and M12 fuel systems are for many professionals and DIY enthusiasts. But there is a strong power coming…well, a lot of batteries! Anyone with multiple packaging knows the frustration of scattered chargers, tangled power cords, and the battery that rolls in a toolbox or drawer. This is confusing, inefficient, and may even pose a security risk. This is where a dedicated Milwaukee battery holder becomes the unsung hero of the workshop organization. And more and more 3D printing Becoming the preferred method to create these basic organizers.

Battery Blue: Why Organization Important

Using batteries in photovoltaics is not only annoying, but not only annoying. It kills productivity. Searching a bunch of tools to find a specific rechargeable battery (half full? Death?) wasted precious time. Traditional storage methods – throwing them into a bag or having them accumulate near a charger – usually results in:

- Physical damage: scratches, dents, or even terminal damage impact or contact with other tools.

- Charging confusion: It is difficult to identify battery charged and uncharged.

- Trip danger: wires and batteries scattered on the floor.

- Lost Charger: Separate the charger from its usual location.

A carefully designed holder specifically for Milwaukee M18 or M12 battery profiles solves these issues gracefully, ensuring your critical power supply is secure, easy to access and identify.

Advantages of 3D printing: Customized to satisfy durability

While there are universal organizers, 3D printing can provide battery holders with new levels of tailored functionality and resilience:

- Perfect for: Count per millimeter. The 3D printed bracket can be designed accurately to shake the precise contour of the M18 or M12 battery. This eliminates the rattle, ensures that the terminal is protected and prevents accidental falloff. Models that are suitable for both battery types can also be implemented.

- Rock solid material: Forget the fragile plastic bin. Advanced 3D printing materials offer excellent strength and durability:

- ABS: Tough, impact resistance, good thermal stability – ideal for seminar environments.

- PETG: Combines excellent strength, toughness and chemical resistance. Not as easy to warp as ABS and is highly durable.

- Nylon (PA): Provides excellent toughness, flexibility and wear resistance, perfect for high use scenarios.

- Asa: Similar to ABS, but with excellent UV resistance, it is ideal for holders who may be used or stored outdoors.

- Smart features and modularity: Design innovation flourishes with 3D printing:

- Charging indicator slot: A clear view of the window allows you to see the battery’s fuel gauge status immediately without removing the battery.

- Tags and logos: Built-in slots for labels or embossed labels "charged," "TOLL," or "Waiting for the charges."

- Charger integration: The holder is designed to neatly dock one or more Milwaukee chargers behind or next to the battery. The cable routing channel keeps the power cord clean.

- Installation versatility: Customized base boards or flanges are used for wall-mounted mounting (Pegboard, French cleats, screws), vehicle mounting (van/truck wall) or bench-top locations. Stackable design maximizes vertical space.

- Modular system: Design a series of clips or bolted brackets to expand storage space as the battery fleet grows.

- Cost-effective: Suitable for your customized design Accurate Requirements and workshop layouts, 3D printing is often cheaper and faster than one-time or small batch custom injection molding.

Why partner with Greatlime to meet your precision 3D printing needs?

Create a truly professional, durable and secure Milwaukee battery holder, not just loading STL files onto any printer. It requires engineering insight, material expertise and precise manufacturing. This is Great Good at it.

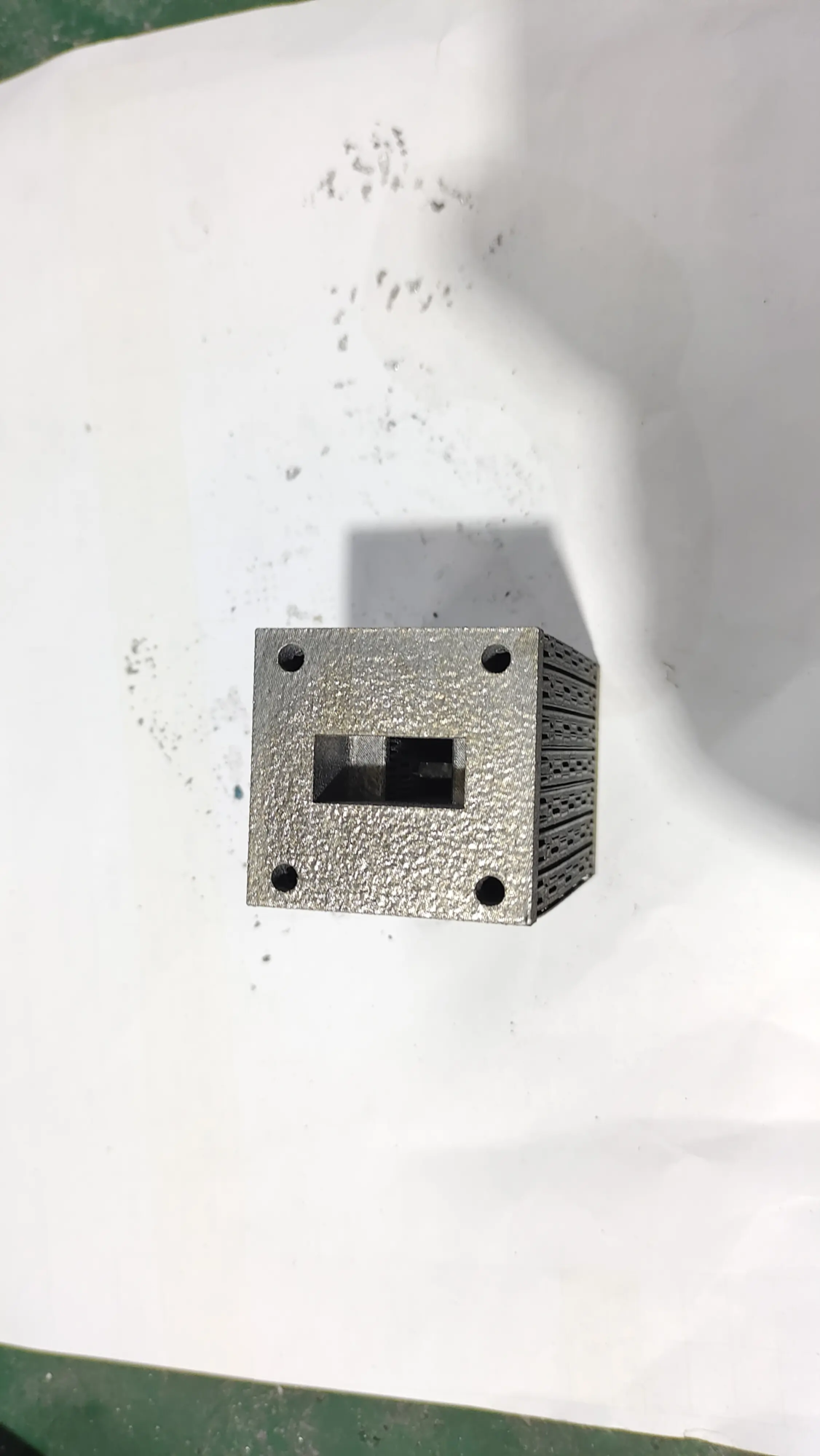

As a leading professional rapid prototyping manufacturer specializing in advanced manufacturing technology Selective laser melting (SLM) – The pinnacle of metal 3D printing – Greatlight has the deep technical foundation needed to transform your design into high-performance, reliable parts. Although your Milwaukee holder may be plastic, the principles of precision and durability are the same.

Our features ensure that your 3D printed battery holder exceeds expectations:

- Manufacturing Expert Design (DFM) Support: Our engineers not only need to print; they work together. We analyze the best printability, material behavior, strength and functionality of the design – it is recommended to improve if needed. Let’s help perfect your holder design for maximum performance with multiple rapid prototype iterations.

- Material mastery: Access a wide range of engineering grade thermoplastics (ABS, PETG, Nylon, ASA) using optimization parameters for layer adhesion, density and surface finish. Even the complex overhang required by the battery clamp can be handled professionally.

- Advanced printing technology: With the most advanced industrial polymer 3D printers, we achieve excellent detail, strength and reliability compared to amateur machines.

- One-stop post-processing: From clearing precision support to smoothing (ABS/ASA steam smoothing), dyeing or custom finishes, we offer a comprehensive service to provide your holder with professional aesthetics and sophisticated features. Even customize brands or labels.

- Quick customization and scalability: Need a specific size change? Special installation hardware bracket? Logo relief? Whether you need a prototype or a crew, our process can quickly turn custom requirements into reality.

in conclusion

Abandon battery chaos. A well-thought-out Milwaukee battery holder is more than just the organizer. This is an investment in efficiency, tool life and workflow smoothness. 3D printing, especially in the context of engineering rigor that experts like Greatlight have applied, revolutionized the way such custom solutions are created. It offers unparalleled customization, workshop-level durability, smart features and cost-effective manufacturing for custom designs. Reclaim your workspace, protect your investments, and ensure you always have strength You need to be within reach.

FAQ: Your Milwaukee 3D Printed Battery Holder Questions Answered

-

Q: Can I print 3D Milwaukee battery holder by myself?

- one: Absolutely, if you have access to a consumer or Prosumer FDM (Fused Deposition Modeling) printer and a suitable filament (such as PETG or ABS). Many free and paid designs for M18 and M12 holders (e.g. Thingiverse, Printables, Cults3d) can be offered online. Ensure good calibration of the printer for strong layer adhesion, especially for key structural features such as clips. For peak durability and reliability in professional environments, it is recommended to use professional printing services such as Greatlime.

-

Q: Are 3D printing holders strong enough to safely hold Milwaukee batteries?

- one: Yes, if designed correctly and printed correctly with the right material. Engineering-grade filaments such as PETG, ABS, nylon (PA) or ASA, create very robust brackets with sufficient fill density (usually the minimum of 30-50% of structural parts) and appropriate wall thickness to securely hold even the heaviest Milwaukee turret without bending, rupturing or allowing the turret to slide. Professional printing ensures optimal parameters.

-

Q: Will the plastic bracket damage my expensive battery?

- one: Well-designed holders can protect the battery. Key features include smooth surfaces to prevent scratches, fixing clips or friction fits, no excessive force on the release button, and protection of electrical terminals (via clearance or contact with non-conductive material). Ensure the internal dimensions are accurate to avoid pressure points. Quality materials such as PETG are chemically inert and do not react with the battery housing.

-

Q: Can I get a holder who holds my Milwaukee charger?

- one: Yes! This is the main advantage of custom 3D printing. Many popular designs integrate slots or docks specifically for standard Milwaukee M18/M12 chargers, often providing space for one or more chargers behind or next to the battery. This will create a dedicated charging and storage station. Greglight can help modify existing designs, or create brand new designs, combined with your specific charger.

-

Q: How much does it cost to a professional 3D printing battery holder?

- one: The cost depends on the size of the bracket (number of battery/charger), complexity, material selected, quantity and finish required. A simple single M18 battery nail is cheap. A sophisticated wall-mounted unit that houses 4 batteries and 2 chargers with cable management will cost more, but with great value. This is often a very valuable investment compared to the cost of custom manufacturing methods or damaged or damaged batteries and search time. Depending on your needs, please contact Greatlight for a specific quote – We specialize in providing high-value precise parts at competitive prices.

- Q: Does Greatlight only print the battery holder?

- one: No! Greatlight is a full-service rapid prototyping and custom manufacturing partner when battery holders showcase what we do for custom organizations. We are good at producing high precision Metal parts are printed with advanced SLM Complex polymer components printed using industrial 3D are used for almost any application – functional prototypes, tools, fixtures, end-use parts across automotive, industrial, electronic, medical and aviation fields. Please contact us for the most challenging prototyping or custom parts requirements.