According to the Resource Library, MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) has developed a right “SlitsNew technologies which allows the manufacture of dynamic devices to cause cables via a single 3D printing process,After printing, the object can be folded, twisted or telescopic.

This technology combines additive design tools and manufacturing methods to simplify the manufacturing process of traditional cable -tunge devices, providing new solutions for bionic robots, dynamic sculptures and interactive fashion products, etc.. The relevant search results will be displayed during the Human-Compost 2025 interaction conference (CHI 2025).

Research context

Cable drive devices are widely used in bionic robots, dynamic sculptures and interactive design fields. These devices are generally based on the adjustment of the cable voltage to obtain precise control of the movement. However, in the traditional manufacturing process, the assembly of cables and mechanical structures requires many manual operations, which has a long manufacturing cycle, a high cost and high requirements for control of the process, which limits its promotion and its application in a larger range of scenarios.

Technological innovation

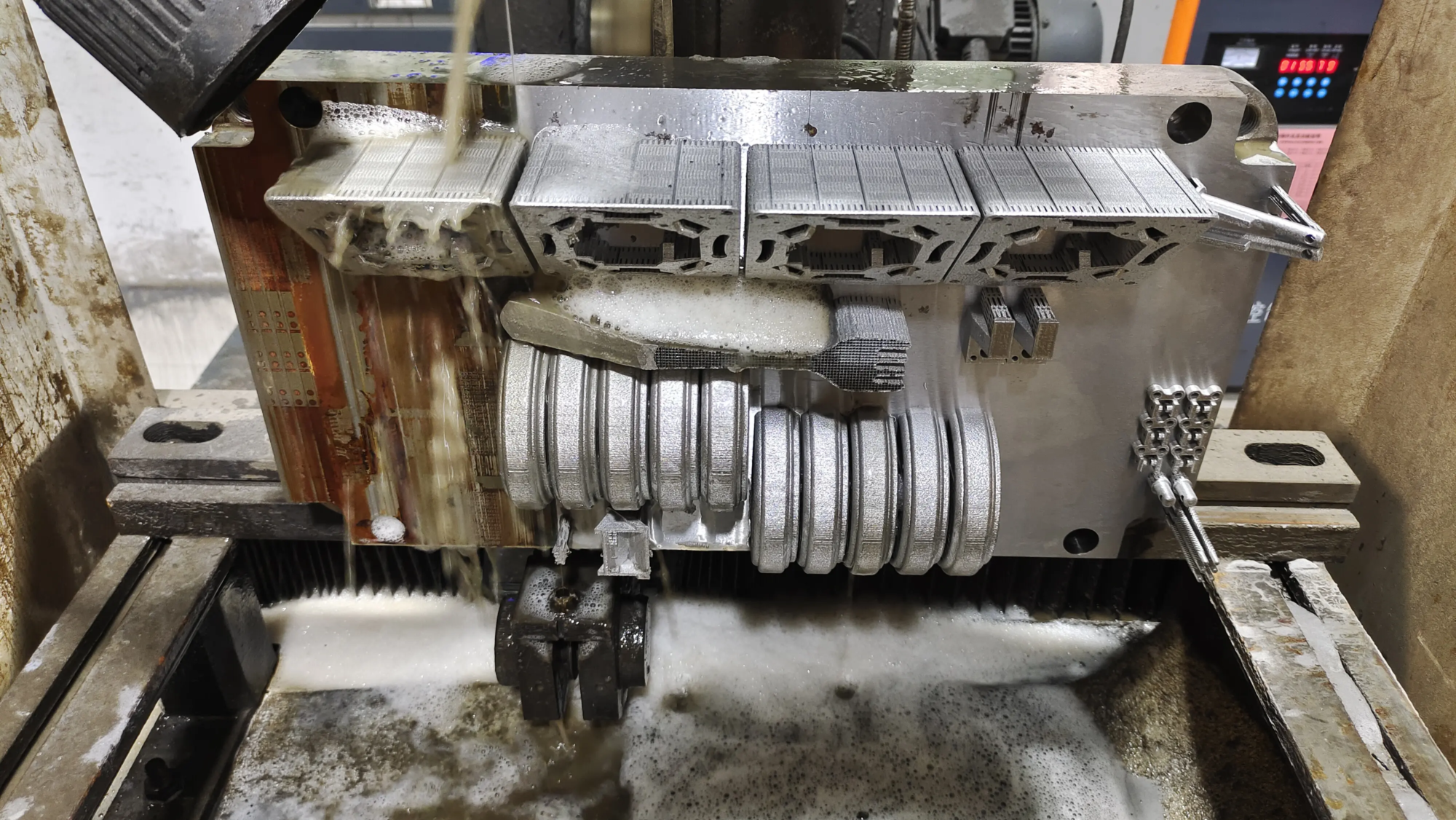

In response to the bottlenecks for the manufacturing of traditional cable drive systems, the CSAIL team has developed XSstrings technology, combining design tools with 3D fusion molding (FDM) to reach the integrated printing of cables, joints and structural parts. Users can complete the structural design and movement adjustment via support software, and the 3D printer automatically completes the integration of cables and overall construction, eliminating heavy post-assembly links.

Compared to traditional manual assembly methods, the overall XSTRINGS production time is reduced by around 40%. The system supports a variety of “primitive movement”, covering the types of basic action such as flexion, torsion, curling and compression. At the same time, users can accurately control the position of the anchor, the layout of the path and the operating interface of the cable, further improving freedom of design.

Application scenarios

The research team has verified the applicability and flexibility of Xstrings through several cases of prototypes:

-Bionic Robot: Print mechanical pliers with independent charging capacities and perform the human -type entry actions thanks to parallel wiring.

– Dynamic art installation: design of open and twisted sculptures, such as wall works inspired by peacock feathers, with rich dynamic effects.

– Interactive fashion design: manufactured clothing or accessories with adjustable parts to improve wear comfort and interactive experience.

– Applications of space and extreme environment: with its automation and integration characteristics, XSTRINGS has the potential to directly manufacture complex mechanical systems in restricted environments such as space stations or extraterrestrial bases, by reducing dependence on external materials and manual operations.

Technological verification and future orientation

To guarantee technical reliability, the search team has carried out more than 60,000 motion cycle tests on the integrated cable printed to check its sustainability and functional retention. At the same time, the team optimized the printing parameters and determined that the optimal temperature was 260 ° C and that the printing speed was 10 to 20 mm per second to guarantee the performance of the material and the structural stability.

In the future, the research team plans to continue to extend XSTRINGS technical capacities in the following directions:

-Egrat more resistant and wear -resistant cable materials to improve the lifespan of the device;

– Explore the wiring methods of the three -dimensional cables to carry out the multidimensional spatial movement;

-Develop the composite structures of soft and hard materials to simulate internal bones and external soft tissues of bionic bodies;

– Develop the possibilities of demand in medical auxiliary equipment, adaptive portable equipment and other fields.

Project support

This study was supported by the financing of the research of the University of Zhejiang and the Mit-Gist project.