New technology using sound for 3D printing is transforming the world of additive manufacturing. Unlike traditional light or thermal printing methods, this technology solidifies materials through sound waves, using high-intensity focused ultrasound to trigger sonochemical reactions in the resin to create 3D structures without physical contact.

The basic principle of this technology is its ability to precisely focus sound waves within the printed material, selectively hardening specific areas through localized cavitation and polymerization reactions to form complex structures.

The unique capabilities of HDSP make it suitable for a variety of scenarios, such as multi-plane object printing, remote manufacturing, and in vivo printing. By encoding cross-sectional information with acoustic holograms, HDSP can simultaneously generate structures on multiple planes and demonstrate the potential of multi-material printing.

In terms of remote manufacturing, HDSP has significant advantages due to the ability of sound waves to penetrate obstacles and is suitable for manufacturing underwater structures such as deep sea waters. In vivo printing uses the remote printing capability of HDSP to generate precise structures directly and non-invasively in the body, providing new possibilities for targeted treatment and implant production in the medical field.

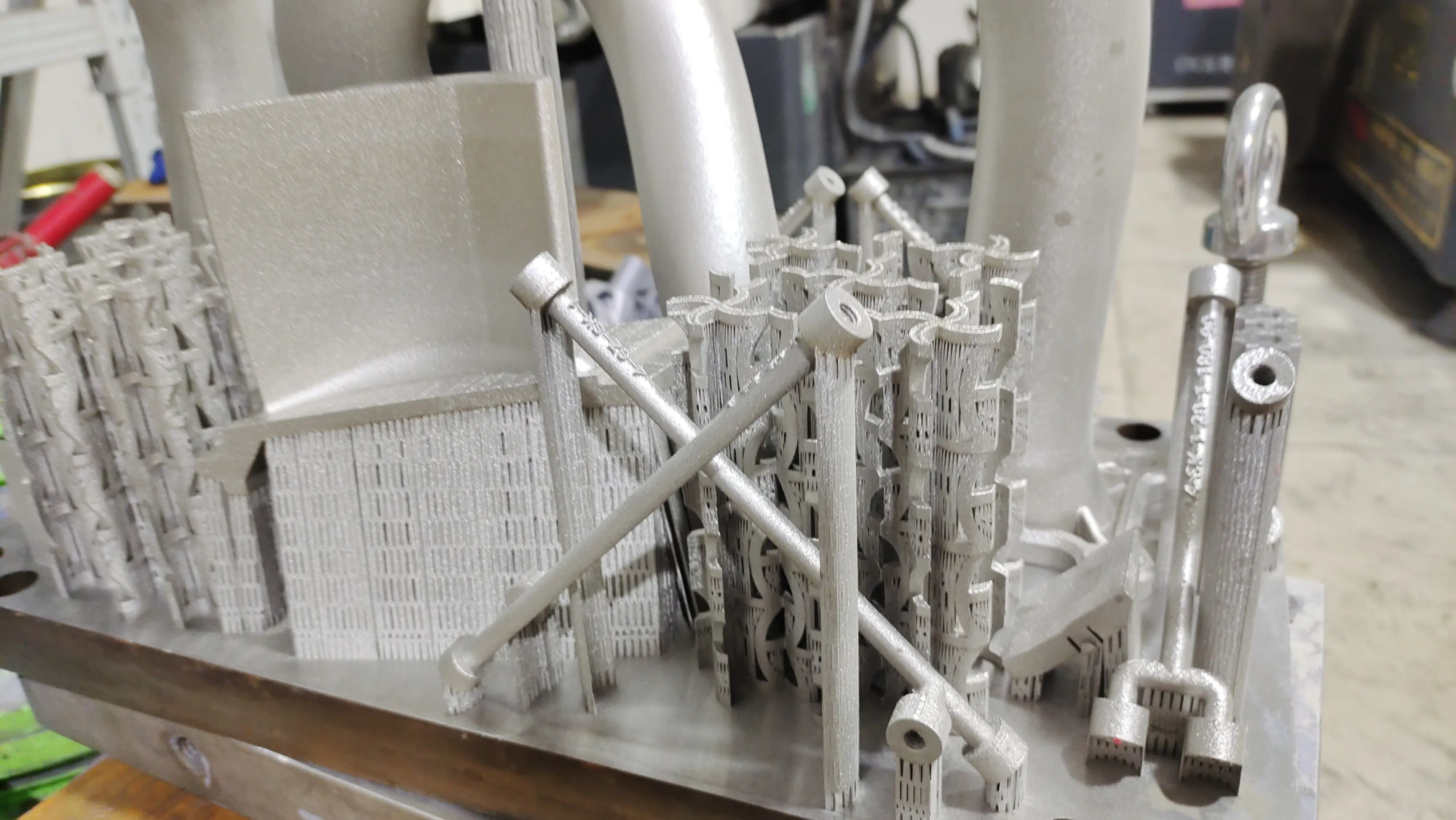

Additionally, HDSP, as a continuous curing process, overcomes the limitations of traditional three-axis printing systems through polymerization chain reactions. Robot-assisted HDSP enables printing of support-free parts and supports the concept of “overlay printing,” creating the conditions for printing complex flexible materials and freer designs.

Generally speaking, HDSP is a faster, more precise and more efficient 3D printing technology. It is suitable for remote manufacturing in complex environments, such as underwater structures, medical implants and even aerospace parts. As this technology continues to develop, it is expected to become an important tool in the 3D printing field in the future, changing the way many industries manufacture.