Drink Responsibly: The Magic of Your Own 3D Printed Pythagoras Cup

Ever heard of a mug that plays tricks? The Pythagoras Cup is an ancient engineering marvel created by the Greek philosopher Pythagoras. This seemingly ordinary drinking vessel hides an ingenious internal siphon. Fill it just right and you can enjoy your drink normally. But if it goes beyond the secret point, will it overflow? Suddenly, gravity and hydrodynamics took over, exhausting all The contents pass through the bottom in a surprising and often embarrassing waterfall fashion! It’s a great conversation starter and a solid physics lesson. Today, with the help of 3D printing, creating your own Pythagoras cup is not only possible, but possible. It’s very accessible and precise. If your goal is durability and polished surfaces (especially on metal), working with a dedicated rapid prototyping expert like GreatLight opens up amazing possibilities.

The charm and mechanism of the cup

Its genius lies in its internal structure. The central column extends from near the base to the edge. Inside the column is a small U-shaped siphon with one leg extending down to the base and another opening near the top of the center column. When liquid stays below the peak of the internal siphon, it becomes trapped. But once the liquid rises more than When bent, water will overflow the top of the siphon. Gravity then pulls the liquid toward the longer legs, creating a siphon effect that continuously drains the cup through the holes in the bottom until it is completely empty. This is a wonderful demonstration of basic physical principles.

Why 3D printing is perfect for the Pythagoras Cup

Creating such complex internal channels manually is very complex. This is where 3D printing shines:

- Precise channels: 3D printers excel at creating complex internal geometries layer by layer, making the precise bends and paths of the siphon easy to work with.

- Complexity made simple: The integrated nature of the cup—which combines the outer container, central column, and inner siphon into one sticky object—is ideally suited to additive manufacturing.

- Material Versatility: Printing basic demos using PLA or PETG? Simple. Need food-safe ceramic resin hygiene or a premium metallic feel? It is also achievable.

- custom made: Want Pythagoras’ face on your cup? Doubles as a pen holder? For espresso or beer? 3D printing makes personalization easy.

Print your mug: options and pathways

How many routes do you have:

- Home Printing (Plastic):

- Find model number: Search repositories like Thingiverse or Printables "Pythagoras Cup" or "Greedy Cup". Many free STL files exist.

- Slice and print: Use slicer software. Hold the cup upright, use supports if necessary (usually for internal siphon structures), and ensure a clean retraction setting to minimize string in the channel. Medium layer heights (0.15mm-0.2mm) provide a good balance between detail and speed.

- Food safety: If drinking, make sure to use food safe PLA/PETG and Consider sealing the interior with a food-grade epoxy coating to prevent bacterial growth. Most household filaments are not inherently food safe for reuse.

- Professional printing services enhance effects and materials: This is where the precision and material choices really expand, especially with metals.

- Metal casing: Metal printing (such as stainless steel 316L or titanium) can enhance your mug’s class. When machined properly, it is extremely durable, corrosion-resistant, has a premium weight and feel, is able to withstand temperature changes, and allows for use in food-safe applications after processing/polishing. Creating complex internal channels through traditional techniques such as CNC machining is expensive; metal 3D printing makes it possible.

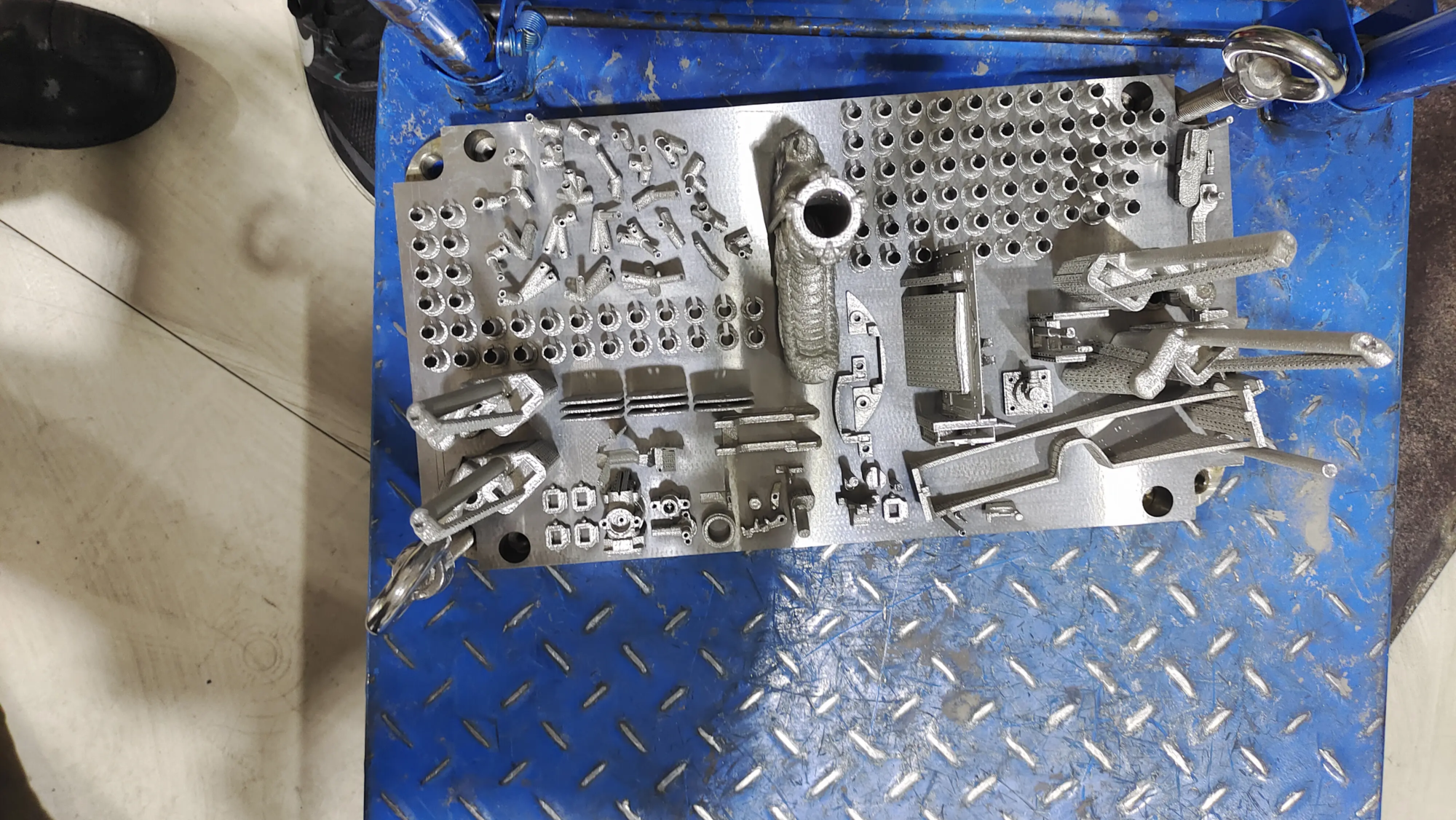

- Enter Daguang: As a leading rapid prototyping manufacturer, specializing in metal parts, huge light Has significant advantages. their advanced fleet SLM (Selective Laser Melting) 3D printers melt metal powder layer by layer with incredible precision. The technique is particularly suitable for creating the complex hollow siphon structures required for the Pythagoras Cup out of strong metallic materials.

- Guoguang advantages: Here’s why partnering with GreatLight to simplify your metal Pythagoras cup:

- Cutting-edge SLM: Get industrial-grade metal additive manufacturing to produce high-density and strong parts.

- Materials expertise: Available in a variety of metal materials including stainless steel, titanium, and aluminum alloys – choose for corrosion resistance and long life.

- Comprehensive post-processing: Crucially, GreatLight offers Full one-stop finishing service. This includes meticulous internal machining/polishing to ensure smooth flow of liquids through siphons and scuppers, precision surface preparation (polishing, sandblasting, tumbling) for aesthetics and hygiene, sealing applications (if required), and necessary treatments such as stress relief or heat treatment for optimal structural integrity.

- Design support: Their team has the expertise to fine-tune your STL files for optimal printability on metal SLM systems, ensuring critical features like siphon bends and drain holes work flawlessly.

- Speed and efficiency: Rapid prototyping is their core business. they specialize in Quick turnaround Customize precision metal parts without sacrificing quality.

Your step-by-step guide to printing (especially using GreatLight)

- Source or design: Get tested STL files or design your own mug using CAD software (Fusion 360, Solidworks, Tinkercad). Focus on precise sipping