In 2023, German startup 1000 Kelvin launched AMAIZE, an AI-assisted tool designed for metal laser powder bed fusion (LPBF) 3D printing. This software combinesHigh-performance computing and physics-based machine learningoptimizing an under-explored area in the 3D printing industry——Toolpath design for LPBF machinesthus effectively avoiding costly repeat testing.

Today, 1000 Kelvin is introducing the latest iteration of its physics-based AI technology at Formnext 2024. AMAIZE 2.0 expands on the success of the original version with more features, not onlyOptimized toolpaths and exposure strategiesand also introduced training based on physical dataIntelligent AI modelhelping designers quickly perform printability checks during the design phase. Additionally, the AI assistant also has:Select the best print direction, generate optimized support structures, optimize exposure strategies, and provide accurate cost estimation and other functions.AccomplishedIntelligentization of the entire printing process,Making metal 3D printing more efficient and intuitive.

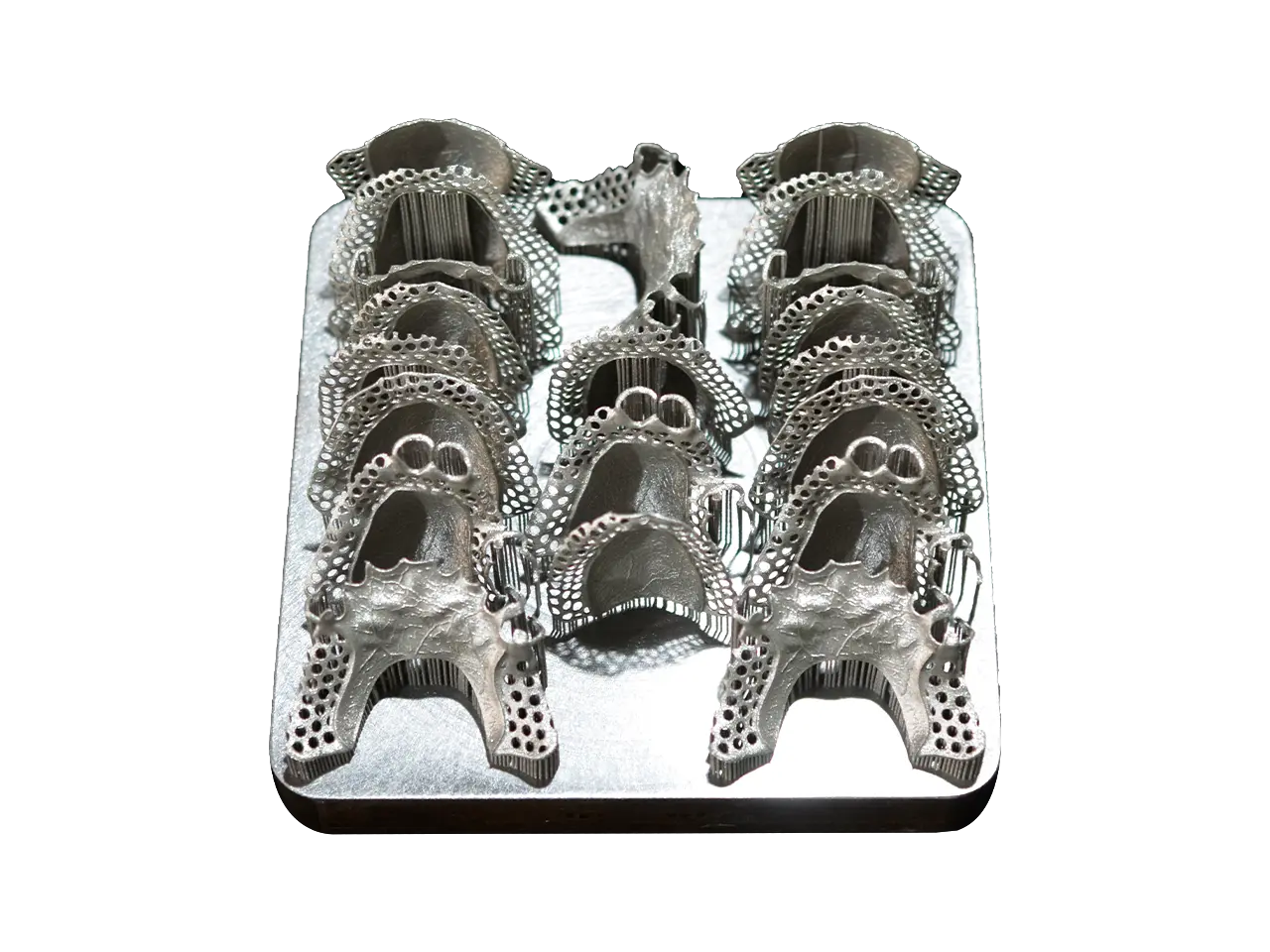

AMAIZE 2.0: Making 3D printing more efficient and reliable

1000 Kelvin indicates that AMAIZE 1.0’s toolpath optimization technology can in some casesReduce print failure rate and warping issues by 80%some customers are even making previously unprintable parts, solving larger and more complex supply chain problems. The launch of version 2.0 adds a number of new features with the aim of reducing costs and failure rates, while allowing users to easily get started regardless of their technical level, becoming a 3D printing solution smarter and more practical metal. Its main functions include:

– Printability Checker: automatically validates and optimizes LPBF designs,Reduce rework cycles by 40%。

– Cost Estimator: provides accurate cost forecasts forQuote accuracy increased by 30%。

– Automatic support structures: optimized construction preparation based on physical models,Save up to 20% on material costs。

– Optimization of the exhibition strategy: optimize parameters using AI to guarantee “The first impression was successful”reducing the failure rate by 50%.

“Previously, customer designs had to go through several tedious steps: build preparation, simulation, printing and rework. If the print failed, you had to contact the customer to change the design, communicate back and forth, authorize and reset the machine. This process often took several days and wasted a lot of material, machine time and energy. With AMAIZE technology, the design can be automatically analyzed, problems can be directly optimized, and printing can be successful the first time.

If this process is verified, AMAIZE 2.0 will revolutionize the additive manufacturing design process. What once required seven or eight attempts by four or five engineers can now be easily accomplished by a single employee.

Beyond the possibilities of additive manufacturing

Currently, 1000 Kelvin is focused on the additive manufacturing (AM) sector, but the potential of its technology clearly extends beyond the 3D printing industry. Initially, AMAIZE was trained on large amounts of physical data to optimize toolpaths for laser powder bed fusion (LPBF). Today, its functions have been expanded to support generation, cost estimation and other areas.

In the future, this technology could be applied to other additive manufacturing methods, such as electron beam metal printing or directed energy deposition (DED). If AMAIZE can succeed in the field of metals, its application in the field of polymers is not unimaginable.

In addition, as AI technology penetrates almost every industry around the world, 1000 Kelvin also has the opportunity to further develop its technology and ultimately realize the automation transformation of the entire industry. the manufacturing industry. The key to all of this is resources and time. AMAIZE’s development journey is undoubtedly a source of inspiration for the future intelligent transformation of the manufacturing industry.