The SLS tag you put on yourself is more catchy

For three consecutive years, three models, from SLS3540-Pro to SLS2030, then to SLS1518, became more and more familiar with the SLS road. So much so that we almost forgot that it started with SLA, but now he presented a variety of technologies such as SLS, SLA and DLP to form a complete product matrix.

If you want to find a business to compare it, you can call it the “Chinese version of Formlabs”.

Back to the article, Zongheng Additive recently published the SLS 3D quality of office SLS1518, at the price of only 59,999 Yuan. But before officially introducing this device, let’s talk about what 3D SLS printing is.

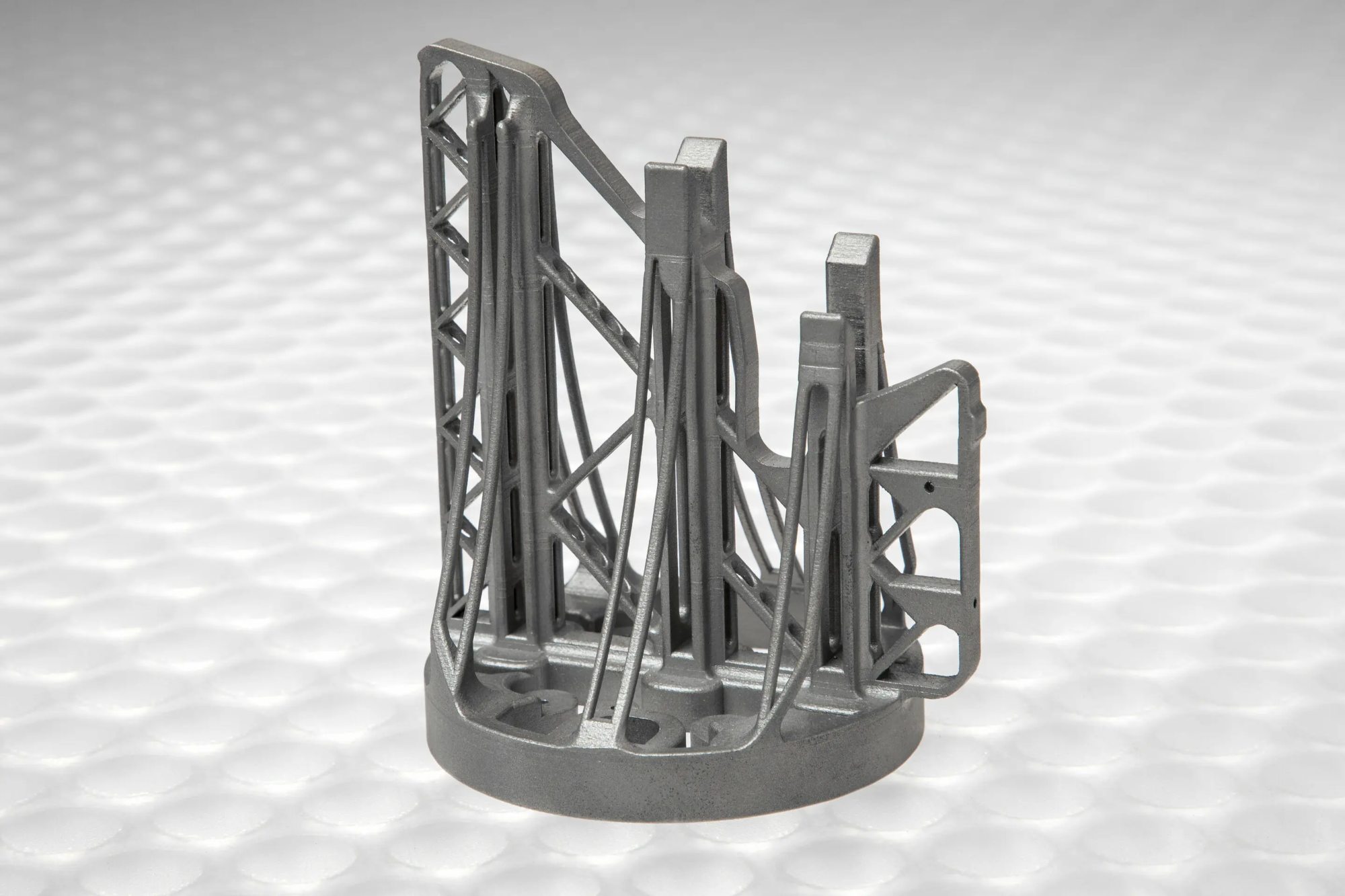

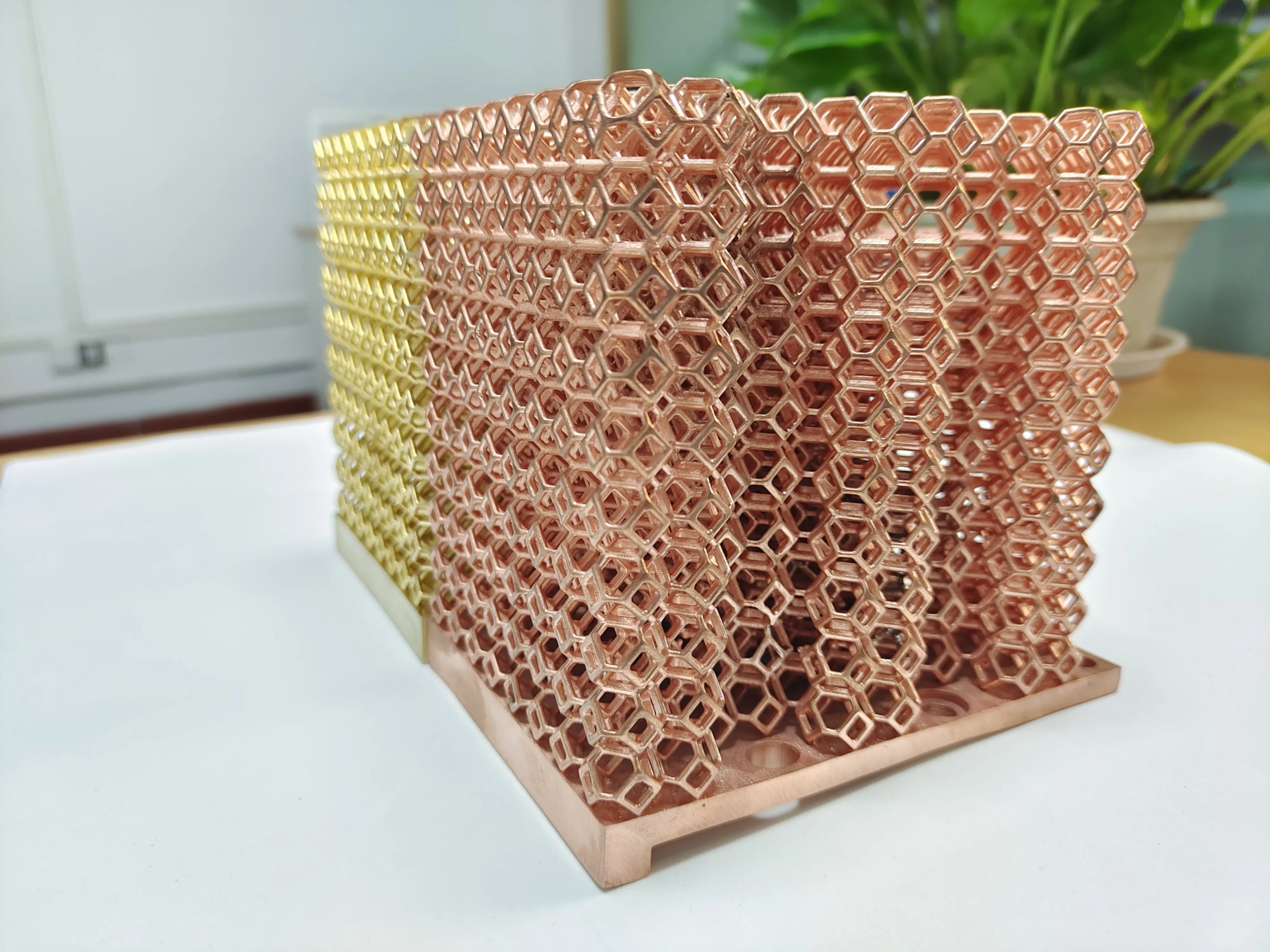

In fact, selective 3D Laser (SLS) 3D printing technology is from the 1980s and is one of the first 3D printing technologies. It is formed using a high -energy laser layer by the chipped polymer powder of layer (like nylon), without support structure, can create complex shapes, and the finished product hasExcellent mechanical properties and high temperature resistanceWidely used in aerospace (light supports, engine parts), medical (personalized prosthesis, surgical guides), automobile (functional prototypes, terminal parts) and industrial design (complex structural parts).

From the point of view of the device, the SLS 3D printing technology “Large industrial grade“And”Small office level“The trend of polarization. On the one hand, large -scale equipment pursues multiple lasers, large and automation to meet the needs of aerospace and automotive manufacturing for the integrated molding of complex structural parts; on the other hand, small -scale equipment focuses on businesses and low -cost educational institutions and educational institutions and modular institutions and medium and medium institutions.

In this segment, we clearly feel the demand for the growth market for small equipment. However, in the past, most equipment on the market was industrial quality products that cost hundreds of thousands, even millions of yuan, while some office quality equipment was mainly dominated by the American manufacturer Formlabs. However, withVertical and horizontal additivesThe appearance quickly filledSLS printing market at the level of the 3D national officeWhite, and compared to products imported from abroadMore price advantage。

Over the past three years, the 3D 3D printing equipment of Zongheng Additive SLS has been iterated once a year, and the price has become more and more affordable, which makes it really more affordable for more people. SLS3540-Pro Price in 2023398,000 yuanSLS 2030 in 2024 fell to198,000 yuan. In 2025, I thought that the new SLS1518 would be at the price of more than 100,000 yuan, but the price was directly removed59999Yuan.

The additive Zongheng refers to SLS1518 asFourth generation SLS technologyThe culmination of the big one, so what are the differences? Discover.

1. Hardcore performance upgrade, pierced by the industry’s strangulation neck

Equipped with a high power high power and industrial quality galvanometer systemThe laser energy density is 90% higher than that of traditional equipment, and combined with a self-developed slicing algorithm, it can be controlled with precision.± 0.1 mmThe precision of the molding can be stable even for complex structural parts such as hollow mesh and thin walls, with a surface roughness as RA 12 μm.

In addition, the device supportsSustainable powder supplyAnd reserve an nitrogen interface to reconstruct the powder in real time during the printing process to ensure the realization of active materials such as PA11, the materials reinforced in carbon fiber and other active materials.Zero oxidation sinteringThe rate of return increased to 98%.

2..

Its fully automatic post-processing systemIt incorporates the cleaning, sieving and mixing powdered and combined 10 L powder tank functions, which supports continuous production, which not only reduces 60%labor costs, but also controls the material of material waste at less than 5%.

In addition, the equipment is equipped7 -inch industrial touch screenAn integrated health monitoring system can be used to warn an abnormal attenuation of laser power, temperature fluctuations and other real -time anomalies, considerably improving the efficiency of the operation and maintenance of 40%.

3. Design based on the scenario to meet the needs of small and medium -sized enterprises

SLS1518 not onlyCompact structureThe body size is 600 × 550 × 800 mm, suitable for small factory buildings, and supports modular expansion.

In addition, it isEnergy consumption optimization designAverage energy consumption is only 800 W and equipped with an intelligent sleep mode, which effectively reduces energy consumption and saves more than 10,000 yuan electricity bills throughout the year. The SLS1518 is a profitable machine which is compatible with a variety of materials (PA11, PA12, TPU, CF, GF).

As one of the most profitable professional 3D printers at present, the SLS1518 is about to be2025 TCT asia exhibition fays. In fact, its price is much lower than Formlabs Fuse 1, or even less than a third, which makes it an ideal choice for companies and professionals to acquire industrial quality printing capacities at low cost. Of course, in terms of size, although the SLS1518 is smaller than fuse 1, if you need a larger size, you can choose SLS2030, which is also more advantageous in the price.

In addition to SLS1518, vertical and horizontal additives have been built to coverRapid prototype, precision molding, production of terminal partsThe complete product matrix. During the next TCT show, we also have the opportunity to see the following devices:

Industrial SLA Series

Supermaker SLA300 / SLA400: Provides a variety of molding choices, supports high temperature resins and special resins, suitable for car lamp molds, flow of works of art and other applications, with surface accuracy up to ± 0.05 mm.

DLP series in continuous print rosary

DM200 / DM400: Equipped with an ultra-class 4K optical engine, with a layer thickness of up to 50 μm, focusing on dental orthodontic models, figures and other fields, the cost of a single room is only 1/3 of that of traditional crafts.

SLS mass production model

SLS2030: The price begins at 198,000 yuan, suitable for mass production of small and medium -sized nylon parts, with a starting cost as low as 400 yuan per lot. SLS3540PRO: The molding is 350 × 350 × 400 mm, with an annual production capacity of more than 10,000 parts, meeting the mass production needs of aerospace quality composite materials.

About the additive Zongheng

Zongheng Additive Intelligent Technology (Zhuhai) Co., Ltd. was created in 2017 and has committed to “doing 3D industrial printing technology at hand”. As one of the few national companies that fully master SLS / SLA / DLP patents with full technology, the company has provided services to more than 1,000 manufacturing customers, covering eight large industries such as cars, medical care, aerospace, etc., and has delivered more than 2,000 equipment units in total.

Company address: 601, 6th floor, building 2, n ° 12, Futian Road, Phase 2, QIENSHAN Industrial Zone, Xiangzhou District, Zhuhai City

Official Company website:www.zongheng3d.com

Contact details: +86 13727851624