Recently, Professor Geqi’s team, the Department of Machinery and Power Engineering of Southern University of Science and Technology (SUTISECH), has made significant progress in the field of reconstructed 4D printing technology . They developed a covalent network-shaped memory polymer (MRC-SMP) with high mechanical performance, which can be used for high-resolution digital processing (DLP) 3D printing (DLP), which achieved successful reconstruction, large deformation and high precision 4D printed high precision 4D high precision 4D high precision 4D high precision 4D high precision high precision 4D high precision high precision 4D high precision high precision 4D high precision high precision 4D high precision high precision 4D high precision high to high precision 4D to high precision 4D to high precision 4D to high precision 4D .

The results of this research are “Can reconstruct 4D printing by self-adapting coordinated mechanical stability of polymer memory shape memory“The title, published in the journal “Scientific Progress”.

Research presentation

Traditional shape memory polymers (SMPS) are often used in 4D printing and have a high modulus. In recent years, research attempts to introduce adaptive network (CAN) into SMPS to achieve a variety of permanent shape reconstruction, but the existing dynamic covalent SMP can be printed. It is difficult to take care of it.

To solve these problems, the MRC-SMP materials developed by Professor Geqi have the following characteristics:

- High mechanical properties: have excellent shape memory performance and high deformation capacity.

- Reconstruction: received permanent form by the transpressive reaction.

- High-resolution printing: support DLP high-resolution printing technology.

Innovation

The research team uses DLP printing technology to develop the MRC-SMP network structure with significant deformation behaviors and shape memory characteristics.

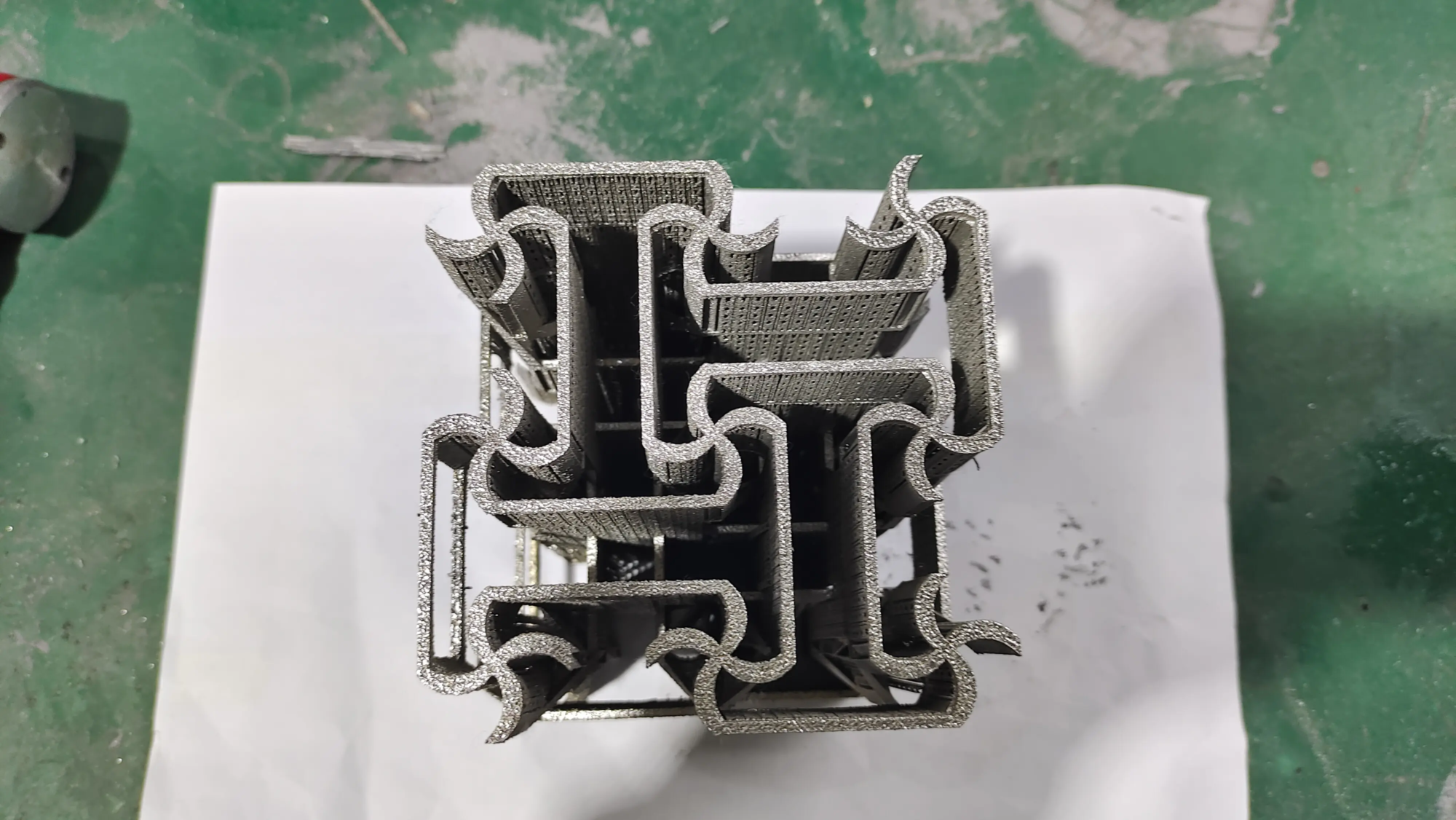

In addition, the material has high-intensity welding ability, which can make complex structures through welding and shaping. For example, by welding three MRC-SMP array structures and one MRC-SMP connector, it forms a mechanical gripping point that can grip heavy objects. The grasping hand can be returned from the development state to the grasping state through the process of shape memory to complete the task of lifting heavy objects.

The team also combines the reconstruction features and multi-material printing technology of MRC-SMP to quickly create a three-dimensional memory origami structure. Taking MRC-SMP as deformed hinge, high intensity optical solidification resin as rigid surface, successfully building high rigidity at room temperature and can resist dirt structure.

Meaning of research

This result shows the application potential of MRC-SMP in high-precision manufacturing and intelligent structure design. It not only improves the application of 4D printing, but also greatly shortens the manufacturing time of complex shape memory structure and promotes the practical application of shape memory materials in multiple fields.

MRC-SMP’s high temperature deformation performance and high precision printing ability provide more opportunities for innovative design in the fields of mechanical structure, intelligent equipment, and also provide more inspiration and technical support for future intelligent manufacturing.

Research support

The study was funded by the National Natural Science Foundation of China, the Pearl River Talent Program of Guangdong Province, the Guangdong Natural Science Foundation of China and the Shenzhen Science and Technology Innovation Committee. The first author of the paper is Li Honggeng, an assistant researcher in the Department of Machinery and Power Engineering, and Professor Ge Qi as the communication author.