On January 10, 2025, according to the resource library, the leading 3D printing solutions supplier in the world Stratasys Ltd. Mindful Manufacturing ™ ESG (Environment, Society and Governance) and sustainable development reportEssence This report fully demonstrates the latest achievements of the company in the field of sustainable practice and ESG according to the standards of the global report initiative and referring to the standards of the Committee for Sustainable Accounting Standards.

Reduce the environmental impact

According to the report, Stratasys has obtained certain results in reducing environmental fingerprints. In 2023, the company used 778,365 kWh of renewable energy to avoid 554 tonnes of greenhouse gas emissions of 554 tonnes of carbon dioxide, which is equivalent to planting almost 9,000 trees. In addition, the company’s water resources decreased by 11.7% and the intensity of greenhouse gas emissions decreased by 15.5%.

At the same time, Stratasys also extended a certified second -hand printer plan to extend the lifespan of the equipment by renovating and re -evaluating second -hand printers. In addition, certification of ISO 14001 environment management has been obtained in Israel and EMEA. By recycling and returning projects, 590 tonnes of products and components have been used several times to make more the effective recycling of resources.

Improve employee policy

In terms of social responsibility, stratasys launched the “parental parental policy” to encourage all gender employees to benefit from paid parental leave. After the implementation of this policy, the number of employees increased by 17%, whose male employees took into account the majority.

In addition, the score of the company’s satisfaction survey of employees reached 73 years and offers employees 33,713 hours of training to cover professional skills and personal development content. In order to improve customer cooperation, Stratasys has established the “Strategic Industrial Customer Consultation Committee” to communicate more with industry customers.

Research and development of new technologies to deal with challenges

Scott Crump, head of the company’s co-founder and ESG current and climatic affairs, said: “I can apply my innovation experience for more than 35 years in the field of additive manufacturing and promote production and a sustainable development. More technologies adapted to carbon emissions. Research and development.

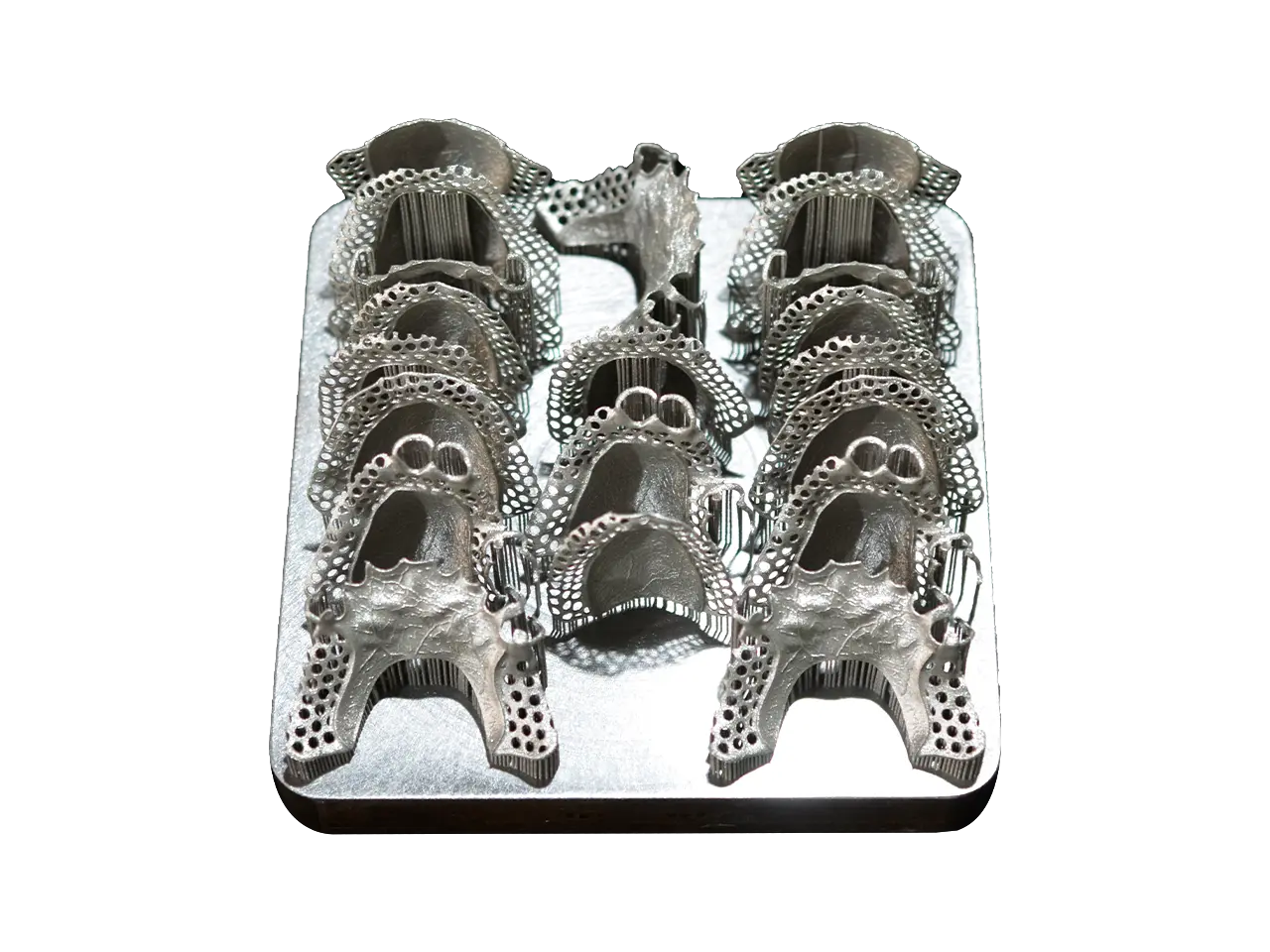

Among them, the stratasys launchedSAF recovery solutionConverted the PA12 powder abandoned in the fusion printer of the pink bed into high quality production components, which has not only considerably reduced the manufacturing cost, but also reduced up to 89% of carbon footprints. In addition, the Grabcad printing software has added an emission estimate function to help users better assess and optimize environmental impact.

The tendency of sustainable development in the face of industry

In terms of industry, the efforts of stratasys are not limited to itself, but the cooperation of the industry it promotes has also injected new momentum into the green future. For example, Seurat Technologies has cooperated with 6K additives to apply 316L stainless steel powder to additive manufacturing, reducing energy consumption and emissions using effective and respectful unimelt technology, which has reduced The exit rate of more than 90%, which has been considerably reduced compared to traditional method emissions.

At the same time, the relevant policy reports of the United Kingdom suggest that the recovery and reuse of key materials must be reinforced to support the production of battery and alloy and reduce dependence on imported resources.

Stratasys showed its practice in the field of additive manufacturing via ESG reports and related measures. In the future, the company plans to continue to explore technologies that can reduce environmental impact and promote industry cooperation to deal with global protection and resource use problems.