The largest 3D metal printing device (additive manufacturing) in my country is officially completed in the Binhai-Zhongguancun scientific park in Tianjin. This device was developed by Professor Liu Changmeng, a team from the School of Mechanics and Vehicles from the Beijing Institute of Technology, focusing on the manufacturing needs of low -cost and high performance marine equipment. The first application of this equipment successfully made the manufacture of a large sandwich structure at the 20 -meter metal points matrix.

“This huge ‘3D printer” pierces the technical difficulties of 3D printing not sustained in suspended structures and produces the manufacture of large sandwich structures at the metal points matrix. “”

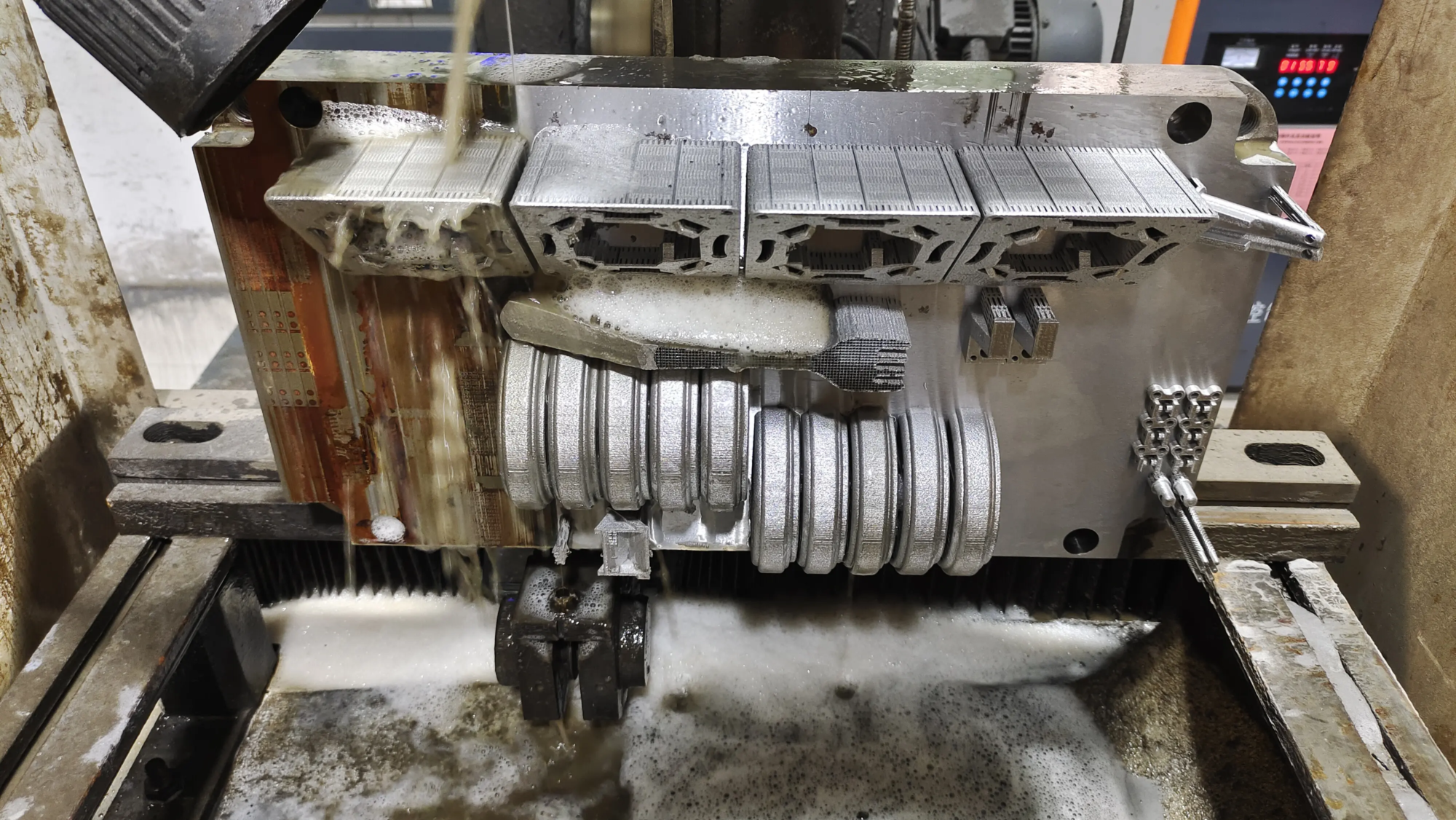

This 3D printing equipment adopts a double gantry design. At the same time, thanks to a fully self-developed and dedicated integrated control system, the equipment can complete differentiated functional services, complex control and high computer intensity tasks.

According to liu Changmeng, the head of the Project Team, the Multi-Arc Parallel 3D Printing Technology of Metal Dot Matrix Structure Breaks Through The Technical Difficulties of Unsupported 3d Printing in Sushedd Structures, and Realizes the Manufacturing of A 20-Meter-Level Large Metal Dot Matrix Sandwich Structure for the First Time. Compared with the traditional manufacturing model, it has the characteristics of integrated design and manufacturing, a Unsupported Manufacturing of Complex Structures, and Lightweight.

“Once the equipment is produced, two types of points matrix profiles are mainly mass produced. One is a light profile, which reduces the weight by more than 30% compared to the traditional method. Reduced by more than 70%, which is both economical, sealing, stability and security.

Over the years, the additive manufacturing team on a transversal scale of the Beijing mechanical and vehicle institute led by Liu Changmeng has targeted the manufacture of marine equipment and developed technologies and ultra-cobutive manufacturing devices extremely at cost. He revealed that the team planned to launch a 50-meter floating platform for the additive steel plaque concrete structure by the end of 2025 to check the modular construction method and the full applicability of the marine environment.

The team also plans to build the first first-kilometer marine floating platform in the Bohai Sea, using wind energy, solar energy, wave energy, hydrogen energy and other renewable energy sources to form an effective effective marine energy development platform to guarantee the construction of the floating bases of the sea of my country.