China’s largest metal 3D printing (additive manufacturing) device was recently officially completed in Tianjin Binhai-Zhongguancun Science and Technology Park. This device was developed by the team of Professor Liu Changmeng from the School of Mechanical and Automotive Engineering at Beijing Institute of Technology, focusing on the manufacturing needs of low-cost, high-performance marine equipment . The first application of this equipment successfully produced a 20 meter wide metal mesh sandwich structure.

“This huge ‘3D printer’ overcomes the technical difficulties of unsupported 3D printing of suspended structures and realizes the manufacturing of large wire mesh sandwich structures, said Liu Changmeng, compared with traditional manufacturing models, this large wire mesh is a new method of structure.” 3D printing has the characteristics of integrated design and manufacturing, support-free manufacturing of complex structures, and lightweight.

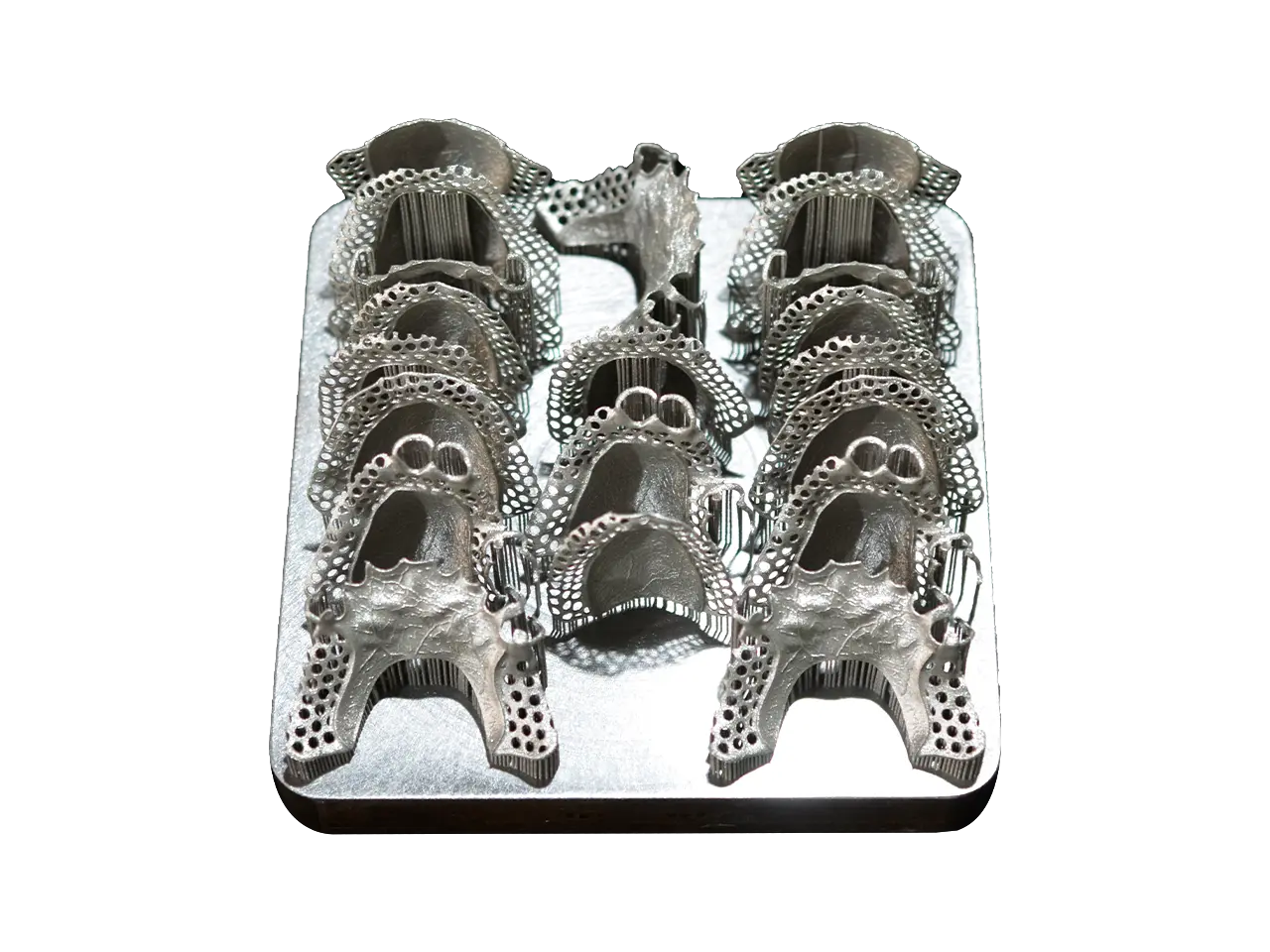

This 3D printing equipment adopts a double gantry design. One side of the gantry carries 24 print heads, which can realize multi-arc collaborative molding of large structural parts; realize the synchronization of several small structural parts. At the same time, this equipment can realize differentiated functional services, complex controls and IT resource-intensive tasks through a dedicated integrated control system completely developed by itself.

According to Liu Changmeng, head of the project team, the wire mesh structure multi-arc parallel 3D printing technology overcame the technical difficulties of unsupported 3D printing of suspended structures and enabled the fabrication of a 20 meter large scale model. metal mesh sandwich structure for the first time. Compared with the traditional manufacturing model, with the characteristics of integrated design and manufacturing, support-free manufacturing of complex structures and light weight.

“After the equipment is put into production, two types of truss profiles are mainly produced in batches. One is lightweight profiles, which reduce weight by more than 30% compared to traditional methods. They have good noise reduction and explosion-proof functions and are mainly used in ships, submarines, armored vehicles and large-scale aircraft; the other is inexpensive. Profile, using steel plate lattice concrete structure, the overall cost can be reduced by more than 70%, combining economy, waterproof, stability and safety. In the future, we should use this technology to achieve thousand-meter ultra-levels. large ocean floating platforms, low-cost construction,” Liu Changmeng said.

Over the years, the large-scale additive manufacturing team of the BIT School of Mechanical and Automotive Engineering, led by Liu Changmeng, has focused on marine equipment manufacturing and developed technologies and very large and very low cost additive manufacturing devices. He revealed that the team plans to launch a 50-meter floating platform with an additively manufactured steel plate lattice concrete structure by the end of 2025 to verify the global applicability of the method. modular construction and resistance to marine environments.

The team also plans to build the world’s first ocean floating platform in the Bohai Sea, using wind power, solar power, wave power, hydrogen power and other sources of energy. renewable energy to form a comprehensive and efficient ocean energy development platform for my country’s large-scale ocean floating platform. Provide a guarantee for the construction of the base.