The Xiongan Wings, as the iconic building of the Xiongan New Area, rise from the ground. And its red “wings” are made in 3D printing.

In fact, 3D printing has been widely used in the construction field, including 3D printing park in Shenzhen, Liuyun 3D printing bridge in Chengdu, 3D printing bookstore in Shanghai, B&B of 3D printing in Hebei and the 3D printing hotel in Gansu. These projects Covering everything from public facilities to cultural spaces and accommodation services, it demonstrates the broad prospects of 3D printing in the construction field.

According to the resource database, the “Xiongan Wings” project was successfully selected for the special intelligent construction direction “Key technologies and equipment for sustainable urban development” due to its technological advancement and scale of operation. application in smart 3D printing construction demonstration application in buildings.Key technologies and equipment for multi-scenario information architecture 3D printing software and hardware integration“The project demonstration project is the only demonstration project in the direction of intelligent construction among all the projects selected for the “14th Five-Year Plan”.

As a landmark building of Xiongan Power Construction smart city, “Xiongan Wing” is located on the central axis of Rongdong area. The height of the building is 24 meters, and the total construction area reaches 23,565.49 square meters. The main body is a five-story structure. The two wings of the building are cantilevered and have the shape of an egret spreading its wings. It is functionally positioned as a commercial cultural facility and houses a large multifunctional theater with 400 seats. Conference room with 100 seats, as well as commercial and office spaces.

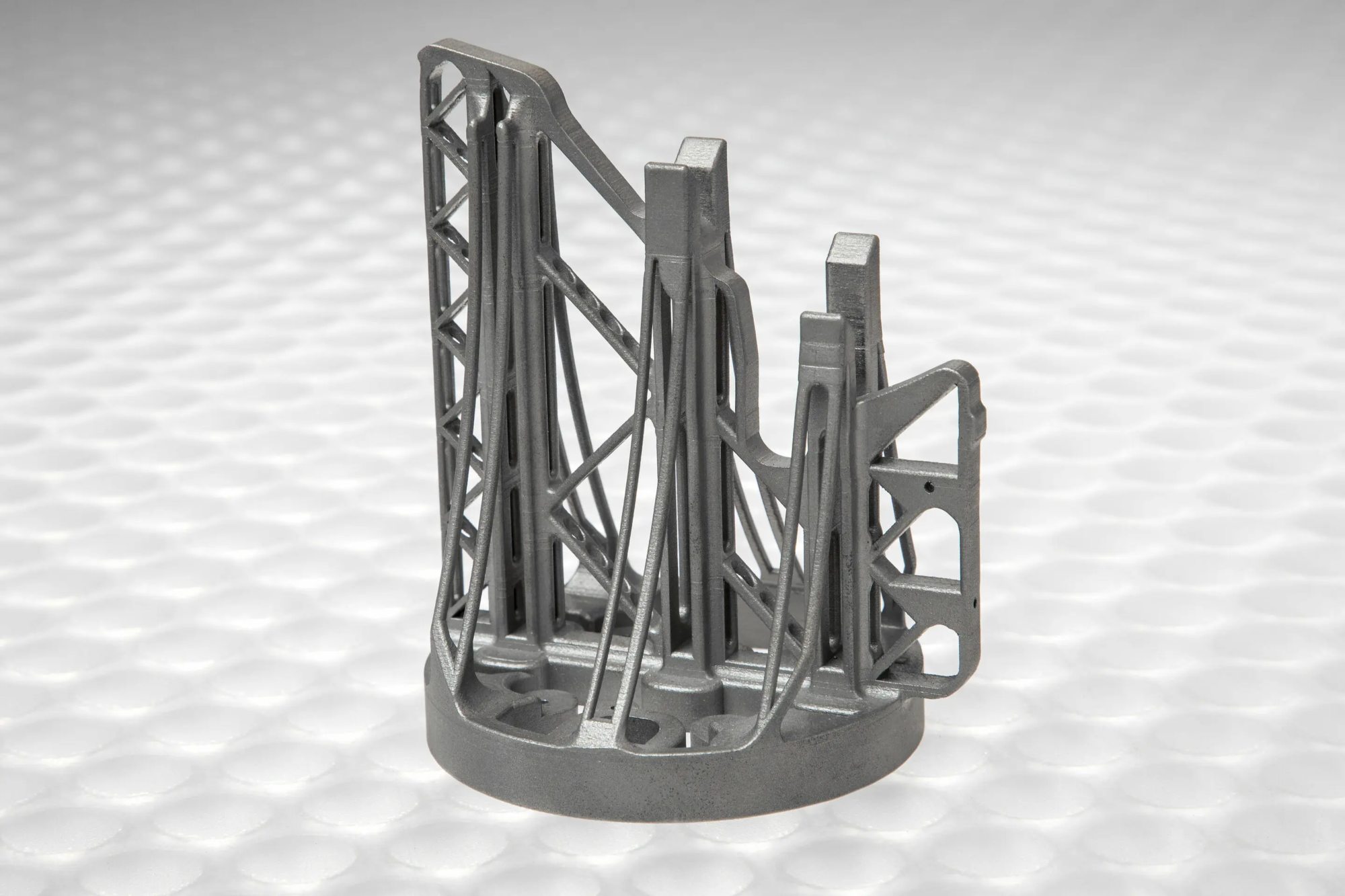

The most distinctive feature of the project’s appearance is the huge red “wings” cantilevered on both sides. The design of this part applies digital design methods, using digital design methods.Modified plastic 3D printing technologyCarry out the treatment and construction of the “double wing” part. Use the on-site prefabricated production model, that is, based on the high flexibility of the mobile construction robot platform, a modular prefabricated production factory can be quickly deployed to the construction site to realize a On-site mass production of high quality and highly customized prefabricated components.

The special-shaped skin parts of the facade are all special-shaped hyperbolic components, which are difficult to position and require high precision. During the construction process, a high-precision on-site full-area detection installation assistance system is based on laser positioning. Large-scale drone three-dimensional scanning systems and technology will be implemented to achieve precise installation of hyperbolic and special-shaped 3D printed components.

According to the resource database, the design unit of “Xiong’an Wings” is Tongji University Architectural Design Institute (Group) Co., Ltd. ; the construction unit is China Power Construction Hebei Xiongan Construction Development Co., Ltd. ; the unit is China Water Conservancy and Hydropower Eighth Engineering Bureau Co., Ltd. ; the special technology production unit is Shanghai Yizhao Technology Co., Ltd.

The “Wings of Xiongan” 3D printing plate has a usage area of 4,600 square meters, and its color meets the red color requirements of Xiongan’s iconic buildings. The material used is the latest developed modified plastic board, which has the ability to be used outdoors for a long time. Compared to ordinary plastics, modified plastics have greater UV resistance and greater fire resistance.

The project is expected to be completed in March 2025. Once completed, it will become the largest construction 3D printing application project in China, and will also be the world’s largest building using 3D printing decorative panel technology made of modified plastic.

According to the latest forecast from Global Market Insights, the global 3D printing market in construction will be worth US$1.5 billion in 2023 and is expected to reach US$103.9 billion by 2032, with a compound annual growth rate of 59.6%. This rapid growth is driven by the increasing demand for cost-effective and sustainable construction solutions.

Compared to traditional construction methods, 3D printing can significantly reduce labor costs and material waste, and support the customization of innovative designs, making it an environmentally friendly alternative . As sustainability becomes a priority for the industry, we believe more construction companies will choose 3D printing. As Tian Guanfei, founder of Guanli Technology, an architectural 3D printing company we interviewed previously, said:

“Intelligent construction is an inevitable development trend in the civil engineering industry in the future, and 3D architectural printing technology is the pioneer of intelligent construction.