On January 6, 2025, according to the Resource Library, in order to deal with the long-term problem of the shortage of spare parts in the MQ-9 drone maintenance training, Kennon Nichols, AFET team director MQ- 9 (training on aviation and support equipment) and maintenance n ° 432 Colonel Joseph DEPOIR, group commander (MXG), worked together to buy two Base units3D tuozhu printerAnd special facilities have been built.

“To solve the problem, the limits of traditional thought must be broken. Our team and our colonel are in an innovative spirit, looking for new ways of unraveling barriers,” said Kennon Nichols. Subject to logistical constraints and financial pressures. “The bottleneck due is attenuated.

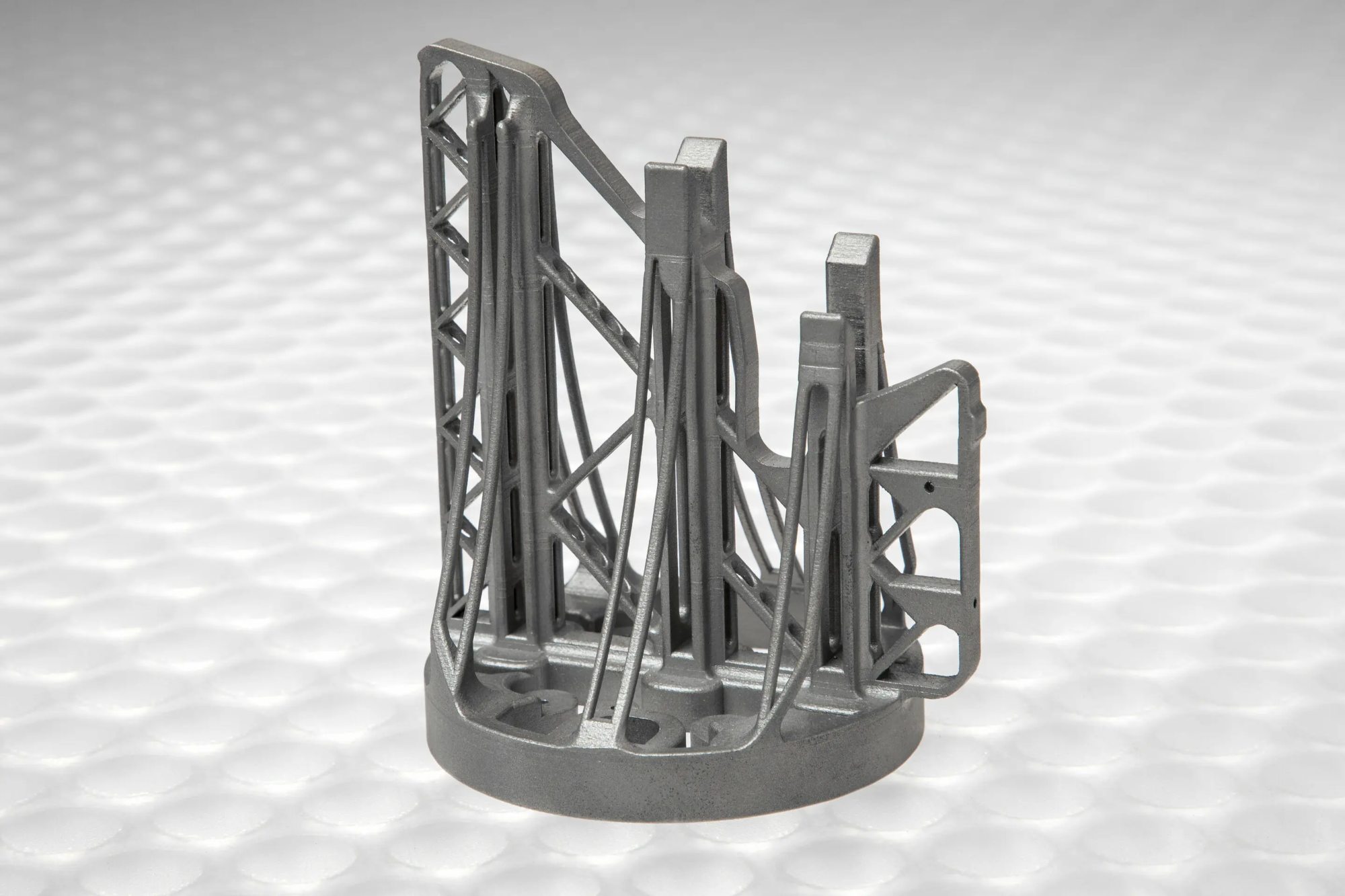

In this program, Remington Young, an expert in the fuselage propulsion equipment and electricity production of the MQ-9 AFETS team, is the backbone of the implementation of technology. Speaking of my experience, Young recalled: “My first 3D printer was given to me by my wife at Christmas 2016. Today, we use 3D printing technology to produce military training equipment, empower pilots With practical skills and even save them. This required $ 10,000 to be manufactured, but now they can be printed for $ 15, which is the trend in the future. »»

In addition, the daily operation of the laboratory is carried out by Eric Pavelka, an expert in planeic equipment. It coordinates printing tasks, optimizes the arrangement of the equipment and guarantees an adequate inventory. “Although the funding was limited, the team agreed that it was worth introducing 3D printers. We have carefully selected and bought the most appropriate equipment, which has considerably improved the efficiency of the training.”

Thanks to 3D printing technology, the MQ-9 Reaper drone maintenance training has improved significant efficiency improvements. This technology allows once expensive and difficult to obtain components to print quickly at a lower cost and in less time, which considerably reduces the preparation time for the training. This is of great importance for military missions which require a rapid response.

Not only that, 3D printing also opens more possibilities for military applications. For example, it can quickly print replacement parts on the mission site, diagnose and repair damage to drones, thus reducing logistics stress and minimizing downtime. This effective solution further improves combat preparation capabilities.

Colonel Joseph DEPOIR, commander of the 432 maintenance group, very praised 3D printing technology: “I cannot describe in words the improvements of the capacity of the team of 432 MXG AFET at the base and more than 800 Maintenance professionals’ `Hunter ” worldwide.

He also pointed out that this technology not only changes current maintenance methods, but also lays the basics of future development of military technology. The components built thanks to 3D printing are not only profitable, but can also achieve rapid iteration, inspired by many areas such as aerospace, national defense and logistics.

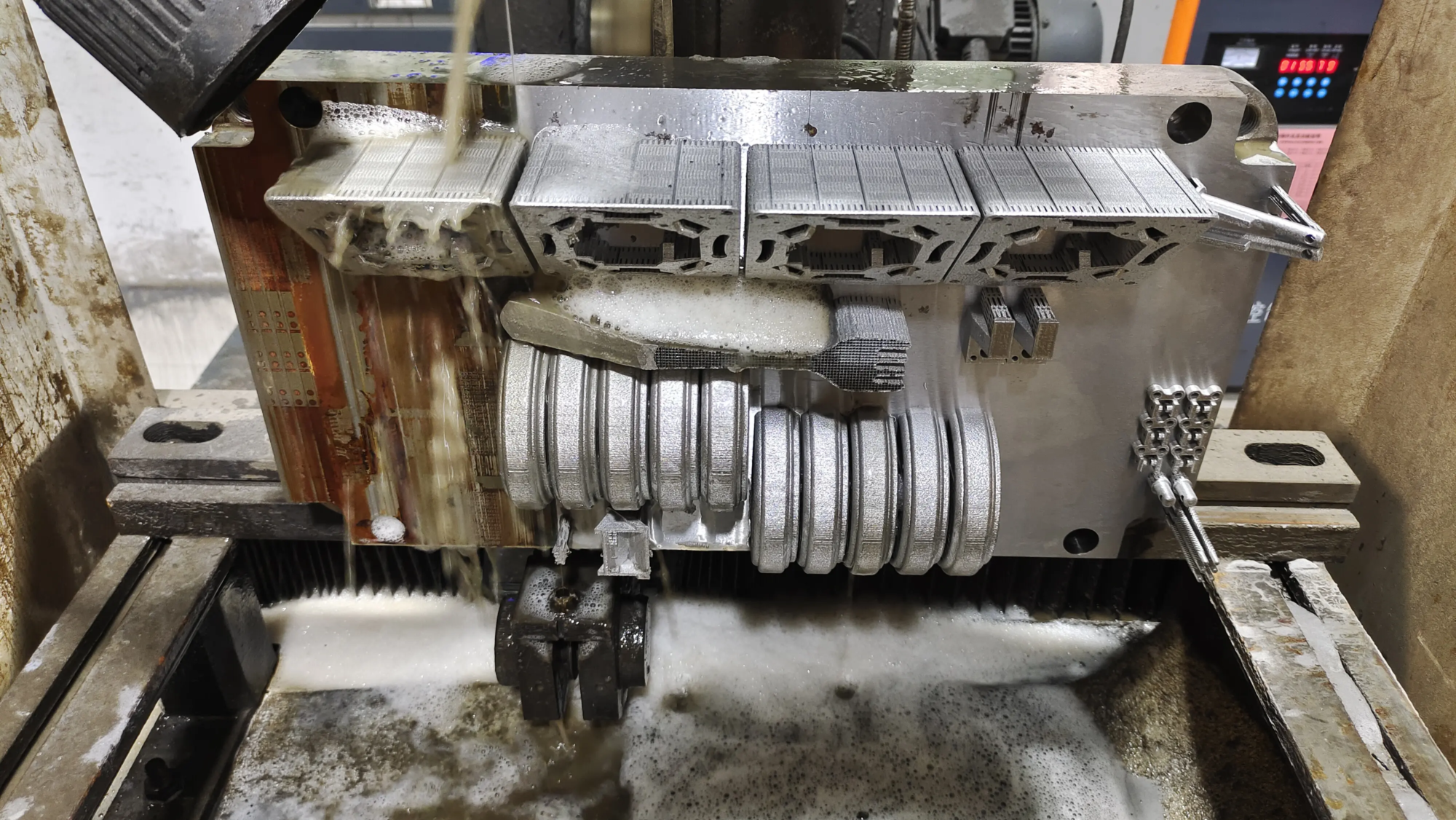

In fact, my country is also trying to use 3D + drones printing to reshape the future supply lines of the battlefield. Recently, it is reported that an Air Force brigade of Northern Theater Command of the People’s Liberation Army of China has in depth tested remote maintenance technology with 3D printing and drone transport as kernel For the first time in an equipment maintenance exercise. In this exercise, a typical battlefield scenario was simulated: the missile launcher could not operate normally due to the damage to key components.

For the future, 3D printing technology will continue to promote military innovation and become an important pillar to improve modern military equipment and combat capacities.