Introduction: The dawn of the new manufacturing era

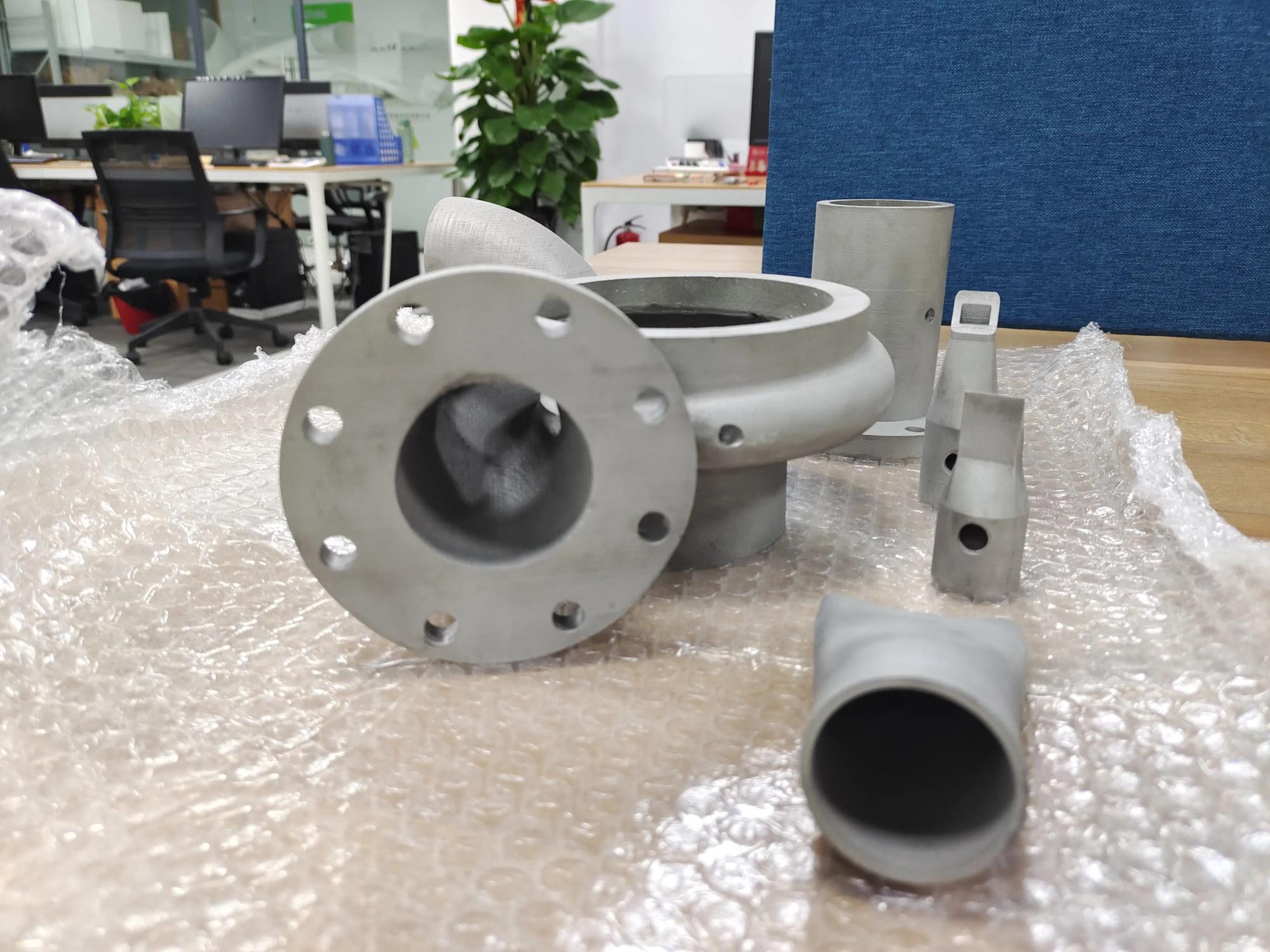

The emergence of 3D printing has completely changed how the industry approaches design and production. Gone are the days of waiting for tools or compromise on design complexity. Today, metal 3D printing (particularly selective laser melting (SLM)) converts digital blueprints into functional high-intensity prototypes in just a few days. It’s not just innovation; it’s a paradigm shift that democratizes rapid prototyping. At the forefront Greatleverages SLM technology to solve complex manufacturing challenges, while providing end-to-end post-processing solutions.

SLM Revolution: Accurate Speed

Selective laser melting is more than just "print";It is the most complex additive manufacturing. High power lasers fuse fine metal powder layer by layer, thereby creating completely dense parts with impossible complex geometries by traditional methods. This technology is great where others are staggering:

- Unparalleled complexity: Build lattice structures, internal channels or topologically optimized components without assembly.

- Material integrity: Achieve nearly 100% density, and the mechanical properties match the forged metal.

- Fast Market: From CAD to physical parts within 72 hours – Accelerate the R&D cycle 10 times.

Gremblight leverages these advantages with industrial-grade SLM printers such as EOS, SLM solutions to ensure repetitiveness in aerospace, automotive and medical applications.

Aside from printing: Greglight’s end-to-end expertise

What is unique is not just the equipment, its overall problem solving. Customers and:

- Post-processing bottleneck: Rough surfaces or residual stresses damage part performance.

- Substance restrictions: Find alloys that balance strength, weight and environmental resistance.

- Scalability: Bridge the prototype to small volume production.

Greglight’s response:

- Integrated post-processing: hips (hot etc., still press), CNC machining, shooting and custom surface treatment (anodized, plated) under one roof.

- Material mastery: Process 30+ metals including titanium (Ti6al4v), Inconel, Aluminum (Alsi10mg) and tool steel, all of which are custom made for hardness or thermal properties.

- Quick Scaling: Prototype 1 unit or production batch of 500+ of the same quality, thanks to AI-driven process controls.

Case Study: Solve "Impossible" part

A robotics company needs a hydraulic valve block with 37 internal fluid channels, which is a nightmare for CNC machining. Greglight’s solution:

- The SLM design was optimized while reducing weight by 52%.

- 316 liters of stainless steel are used for corrosion resistance.

- Delivered within 11 days, leak tested parts (with traditional methods quoted for 6 weeks).

Why choose Greatlight?

As One of the fastest prototype companies in ChinaGREMLIGHT integrates precision and agility:

- Cost-efficiency: Localized production + lean workflow costs 40% lower than that in the West.

- speed: 80% of orders ship within 5 days – It is crucial that startups go public.

- obey: ISO 9001 certified with complete material traceability (ASTM/AMS standard).

- Collaborative Engineering: Work directly with SLM experts to adjust the design for manufacturability.

Conclusion: The future established today

3D printing is more than just a tool; it is the backbone of the next generation of manufacturing. Greatlight embodies this evolution, providing not only SLM printing, but also the strategic partnerships needed to address the challenges of metal prototypes. They turn obstacles into breakthroughs through turnkey solutions that are post-processed across design optimization. Whether you iterate over prototypes or expand production, Greatlight proves that complexity, speed and cost-effectiveness can coexist.

Ready to reimagine your prototype? Get an instant quote or inquiry.

FAQ: Mystical Metal 3D Printing Service

Q1: How does SLM compare to traditional processing of metal parts?

SLMs have complex geometries (e.g., hollow structures) and exotic alloys, but may require tight tolerances (±0.1 mm). For simple shapes, CNC machining is often still cost-effective.

Question 2: Which materials can highlight the process well and can be customized?

We process titanium, inconel, aluminum, stainless steel, cobalt powder and copper. Alloys can be tailored to properties such as enhanced fatigue strength or heat resistance.

Q3: How fast is it "Rapidly" Prototyping with Greatlight?

The standard lead time for SLM printed parts is 3-5 days. Using expedited services, the functional prototype is shipped within 48 hours.

Question 4: What post-processing options are critical to SLM parts?

- Stress relief: Mandatory nature of aerospace parts to prevent warping.

- Surface finish: Used for CNC processing of interface surfaces; bead blasting aesthetics.

- Fashionable: Crucial for fatigue-critical components such as turbine blades.

Q5: Can I use Greatlime to convert from prototyping to full production?

Absolutely. Our SLM system supports batch production of 50-1,000 units with consistent mechanical properties, thus bridging the gap between R&D and manufacturing.

Question 6: How to ensure the quality of parts?

Each build goes through:

- Powder composition analysis (pre-printing and post-printing).

- Layer-by-layer monitoring with intraorganic sensors.

- CT scan/X-ray for internal defect detection (optional).

Q7: Is there a size limit for SLM printed parts?

Our largest printer tool is 500×280×850mm. Larger components can be divided and welded.

Innovation without compromise. Greglight turns additive ambitions into engineering reality.