Recently, the U.S. Department of the Navy (DoN) officially released its first Advanced Manufacturing Strategy, focused on improving parts manufacturing, repair, rework, and reverse engineering capabilities through cutting-edge technologies. The core technologies of this strategy cover many areas such as additive manufacturing, subtractive manufacturing, cold spray, directed energy deposition, coating removal, robotics and automation, data and advanced processing.

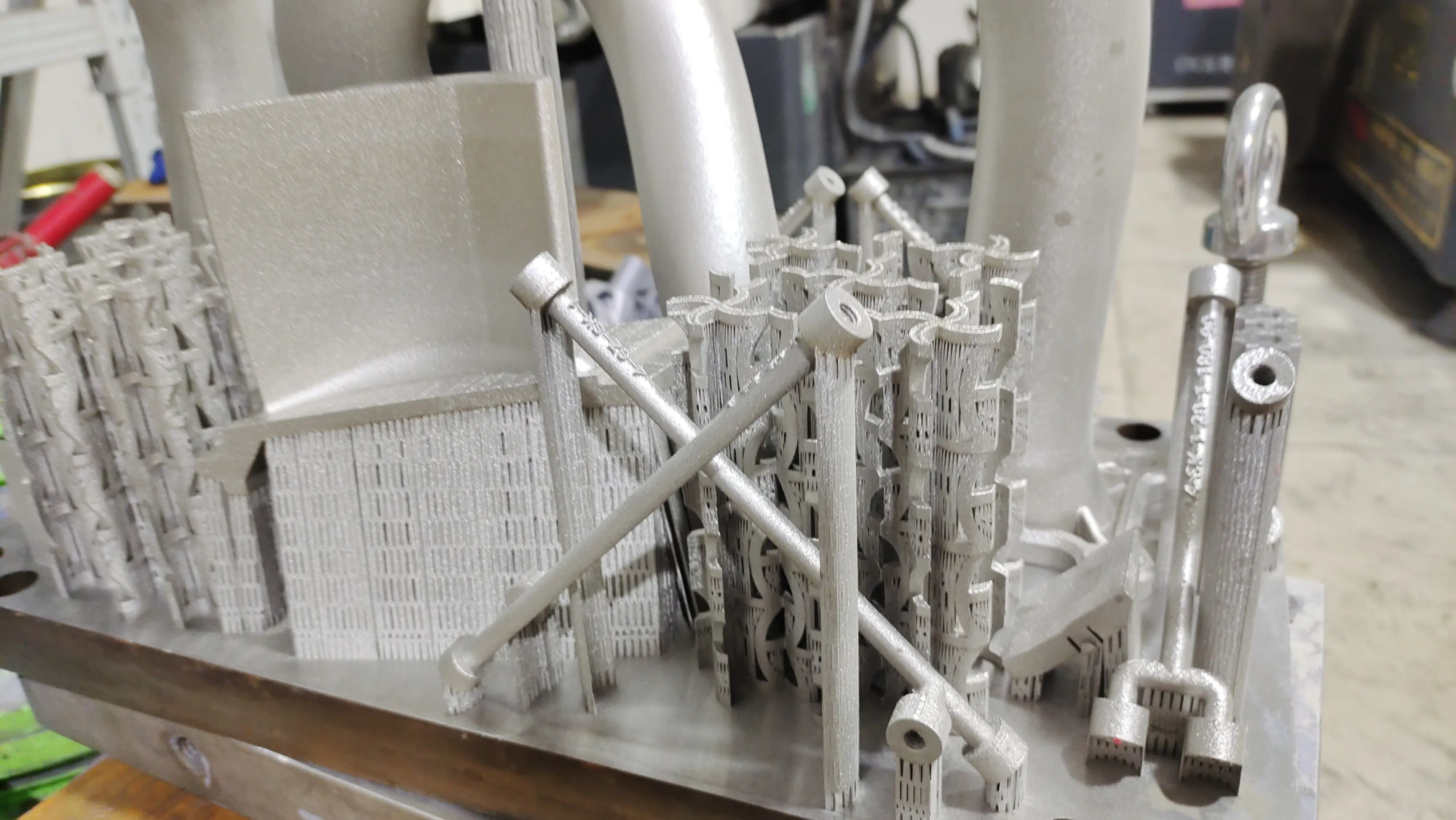

Additive manufacturing technology has become one of the key areas of this strategy due to its flexibility, rapid response capabilities and efficient use of materials. Using this technology, the Navy can quickly manufacture complex parts, achieve small-batch production, and even directly generate equipment components needed for front-line combat.

Nickolas H. Guertin, Assistant Secretary for Naval Research, Development and Acquisition, said during the press conference: “By applying these cutting-edge technologies, the Navy and Marine Corps will continue to maintain global dominance . Department of Defense We will also continue to expand our advanced manufacturing capabilities to provide warfighters with lethal, cost-effective warfighting tools at faster speed and with greater efficiency.

The Navy’s strategy has this time been clarifiedthree coresdirection:

1. Leverage cutting-edge technology in business

By cooperating with the business sector, we introduce the latest technological achievements and promote strategic development.

2. Expand internal capabilities and optimize warehousing systems

Improve internal manufacturing capabilities, optimize existing warehousing and supply chains, and build self-sufficiency for warfighters on the front lines.

3. Deepen cooperation with industry and academia

Fully introduce advanced manufacturing technologies into the design and production process, while promoting the deep integration of these technologies into the supply chain.

Erica Plath, deputy assistant secretary of the Navy for sustainment, emphasized that close commercial cooperation is essential to achieving this strategy. “Partnering with commercial manufacturers and the private sector will give the Department of the Navy access to cutting-edge technology and innovation while significantly improving efficiencies to ensure strategic objectives are achieved. »

In order to promote the implementation of advanced manufacturing strategies in various fields, the Ministry of the Navy clarifiedFive cross-cutting sectorsKey factors:

1. Governance system: ensure effective management of resources and technology.

2. Maturity of manufacturing technologies: Promote the maturity and application of core technologies.

3. Standardization construction: establish unified technical standards to ensure standardized operations.

4. Digital Architecture: Build the digital infrastructure needed to support advanced manufacturing.

5. Workforce Development: Cultivate a pool of high-quality technical talent with modern manufacturing skills.

Marine Corps Brigadier General Forrest Poole believes advanced manufacturing technology will become an important force in improving combat support capabilities. “By properly allocating resources, advanced manufacturing technology can provide critical parts support to the Marine Corps in the field, while establishing a more effective connection between frontline operations and rear support. Applying digital manufacturing technology will ensure that parts are delivered to the right location. specifications and accelerate production and delivery, improving the resilience of logistics systems in everyday and wartime environments.

By integrating cutting-edge technologies, expanding cooperation, and strengthening supply chains, the strategy will provide the Navy and Marine Corps with continued technical support and enhancements to their operational capabilities, injecting new vitality into the landscape of modern warfare. Additionally, as one of the core technologies of advanced manufacturing, additive manufacturing is reshaping the Navy’s combat readiness and sustainment model. Through the in-depth application of this technology, it will provide stronger technical support for future military operations and add new possibilities. modern warfare.