Recently, it was reported that an air force brigade of the Northern Theater Command of the Chinese People’s Liberation Army extensively tested the previous equipment for the first time during an exercise equipment maintenance.3D printingAndTransport by droneAs a basic remote maintenance technology. This technology aims to break the limitations of the traditional logistics maintenance model and provide more efficient and accurate maintenance support on the battlefield. This innovation also constitutes an important source of inspiration for the transformation of future war logistics support models.

In this exercise, a typical battlefield scenario was simulated: the missile launcher was unable to operate normally due to damage to key components. The entire drilling process covers the complete cycle of operations from reporting defects to completing the repair.

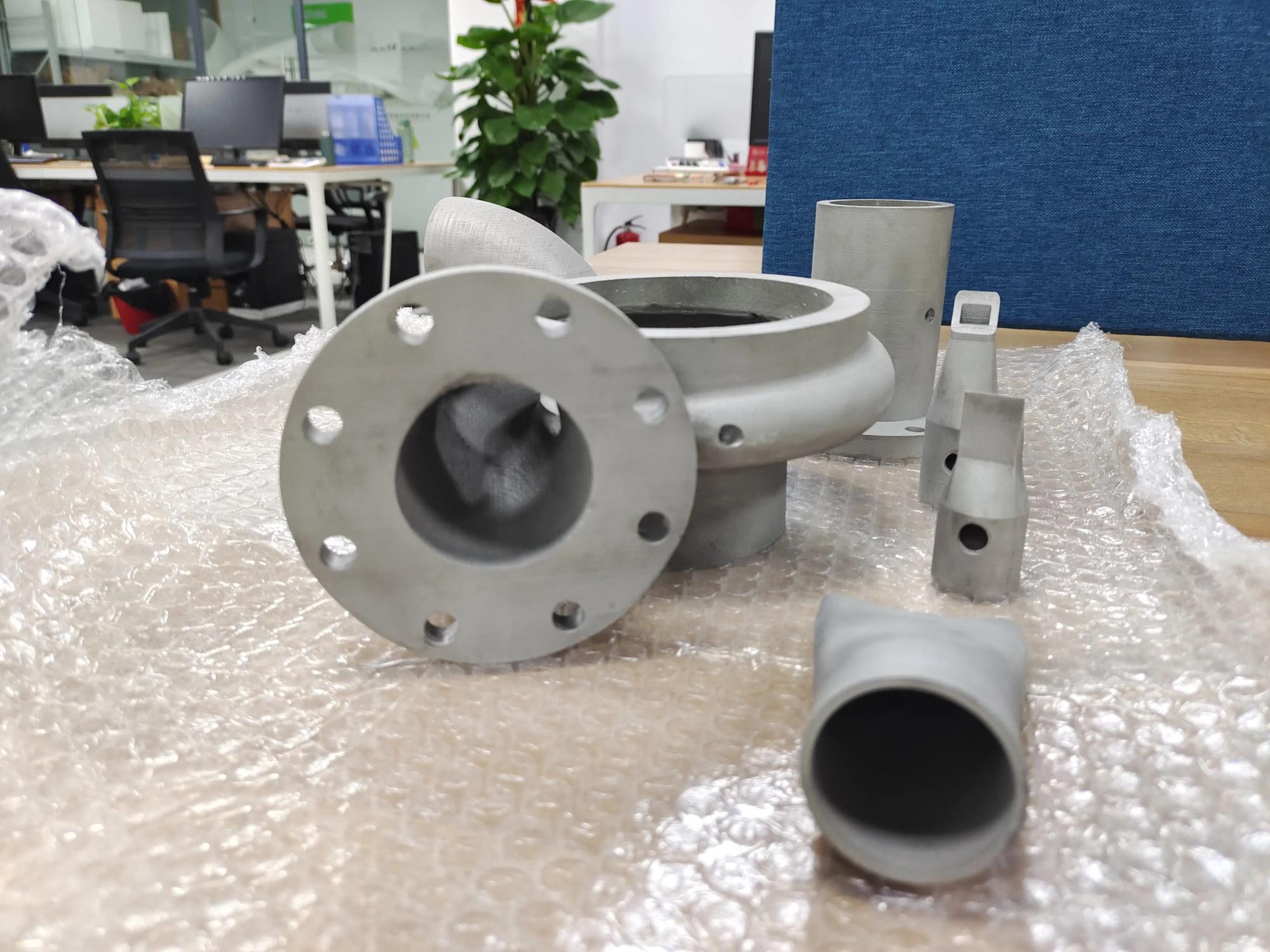

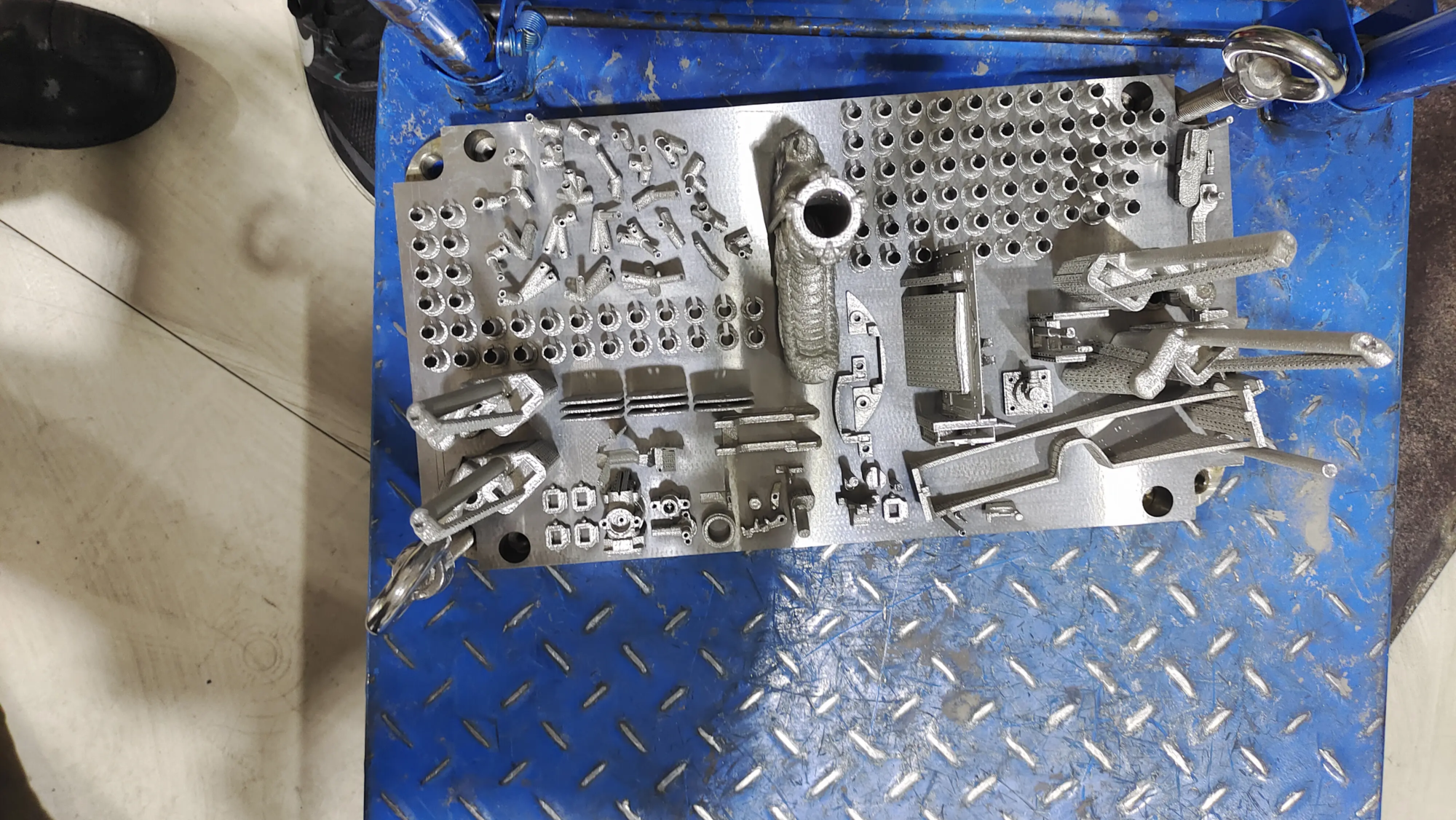

First, the launcher operator uses wireless communications equipment to transmit real-time fault information (including text, images, and video) to the rear maintenance station. Subsequently, the maintenance team quickly designed and generated a three-dimensional model of the faulty part, then used a portable 3D printer to produce replacement parts.

Once manufacturing is complete, parts are efficiently transported to the frontline via drones, avoiding delays and security risks that can be caused by traditional transportation methods. Finally, front-line maintenance personnel receive the parts and quickly complete maintenance tasks with the guidance plans and real-time technical support provided from the rear, thereby restoring the combat capability of the launch vehicle.

The completion time of the whole processOnly a third of the traditional modelfully demonstrating the improved effectiveness of remote maintenance technology in a battlefield environment. In this exercise, the drone’s performance was particularly remarkable. It was able to land precisely in a designated area in complex terrain, ensuring the safe and efficient delivery of maintenance supplies. At the same time, delay bottlenecks in traditional transportation methods are eliminated, significantly improving the timeliness of maintenance support.

This test shows that remote maintenance technology is highly feasible and has significantly improved performance in real combat environments. By integrating 3D printing technology and drone transportation, the People’s Liberation Army has significantly improved its equipment maintenance autonomy and battlefield response capabilities. In the future, with the continued development of related technologies, the People’s Liberation Army is expected to implement remote maintenance applications on a larger scale.

In fact, the US Department of Defense (DOD) has already provided Ukraine with 3D printers capable of rapidly manufacturing key components of military equipment. The U.S. Army is continually expanding its 3D model dataset to meet troop needs. This data facilitates the rapid and safe production of critical parts for ground deployment that have been discontinued by the original manufacturer or are subject to complex procurement processes.

Whether in China or the United States, the combination of 3D printing and drone transportation technologies has demonstrated its enormous potential in the maintenance of military equipment. The maturity and promotion of this technology could significantly improve the equipment maintenance capabilities of armies of various countries and change the logistics and combat models on traditional battlefields.