In recent years, with the acceleration of industrialization, recycling and reuse of scrap metal has become a hot topic.

This method not only avoids the disadvantages of traditional smelting processes such as high energy consumption and long production cycles, but also converts scrap aluminum into high-strength metal alloys in a short time, opening up a new path for the recovery and use of industrial waste. .

Process principles and core technologies

The core of solid phase alloying is to precisely mix scrap aluminum with metal elements such as copper, zinc and magnesium, and make an alloy using PNNL’s patented technology – Processing and Extrusion shear-assisted (ShAPE). ShAPE technology creates friction and heat by rotating a mold, transforming the raw material into a homogeneous alloy in less than five minutes. This process completely ignores the traditional melting bond and shortens the manufacturing cycle from days to minutes.

Research shows that ShAPE technology can form special Guinier-Preston zones during processing. This microstructure significantly improves the strength and durability of the alloy. Compared with traditional recycled aluminum, the strength of alloys produced by solid phase alloying can be increased by up to 200%.

Advantages of efficiency and environmental protection

One of the strengths of solid phase alloy technology is its remarkable energy efficiency. The traditional aluminum smelting process is energy-intensive and has high carbon emissions, while solid-phase alloying is made entirely in a solid state, avoiding the high-temperature operations required to melting and casting. This process not only reduces production costs but also minimizes environmental impact, thereby providing strong technical support for green manufacturing.

Additionally, this technology has a simple process and only requires one step to complete the alloying process. This feature makes it more practical in industrial production.

Broad application prospects

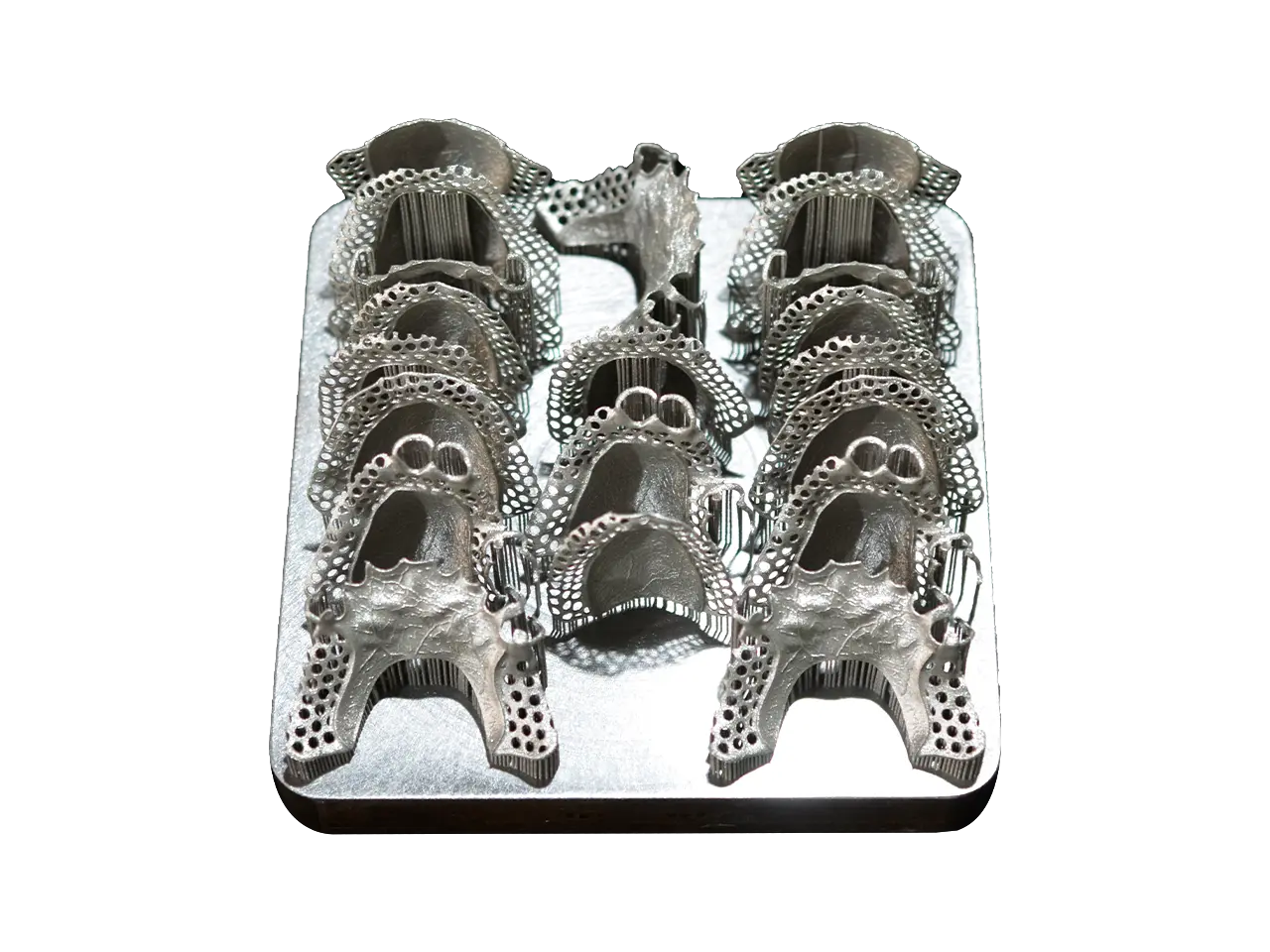

The potential of solid phase alloy technology is not limited to aluminum scrap. The researchers noted that the technique could theoretically work with any combination of metals. In the field of 3D printing in particular, solid-phase alloying offers new solutions for custom alloy materials for technologies such as electric arc additive manufacturing (WAAM). For example, by precisely controlling the alloy composition, the technology can produce metal wires with special ratios such as 2% copper or 5% copper to meet different printing needs.

This capability gives solid phase alloys great commercial value in high-end industries such as aerospace, automobile manufacturing and additive manufacturing. Currently, the project is supported by the US Solid Phase Processing Science Program Laboratory Project. We can predict that with further optimization of the technology, solid phase alloying could become a key driver in the field of metal materials manufacturing.