|

On February 18, 2025, according to the Resource Library, a team of scientists succeeded in a remarkable challenge at Strathclyde University in Glasgow, Scotland: they created a microscope completely composed of 3D printing technology at an ultra-basic cost of less than 50 pounds (around 450 yuan). The body and objective of this microscope are in 3D SLA (photocuur) and transparent resin printing technology, and the entire manufacturing process takes only three hours. This innovative project should completely modify the current high price of medical diagnostic equipment, providing low -cost and high quality diagnostic tools to more laboratories, schools and even developing countries with limited budgets.

Technical details of 3D printed microscopes

The central components of this 3D printed microscope include a single lens with a magnification of 2.9 times and a digital opening of 0.07. Although these parameters are not exceptional in traditional microscopy, their resolution is sufficient to meet the basic diagnostic needs, in particular to carry out a reliable medical analysis under the premise of low cost.

The researchers downloaded the microscope design model from the open-source openflexure platform and added a camera, a light source and a Raspberry Pi micro-computer to further improve the practicality of the device.

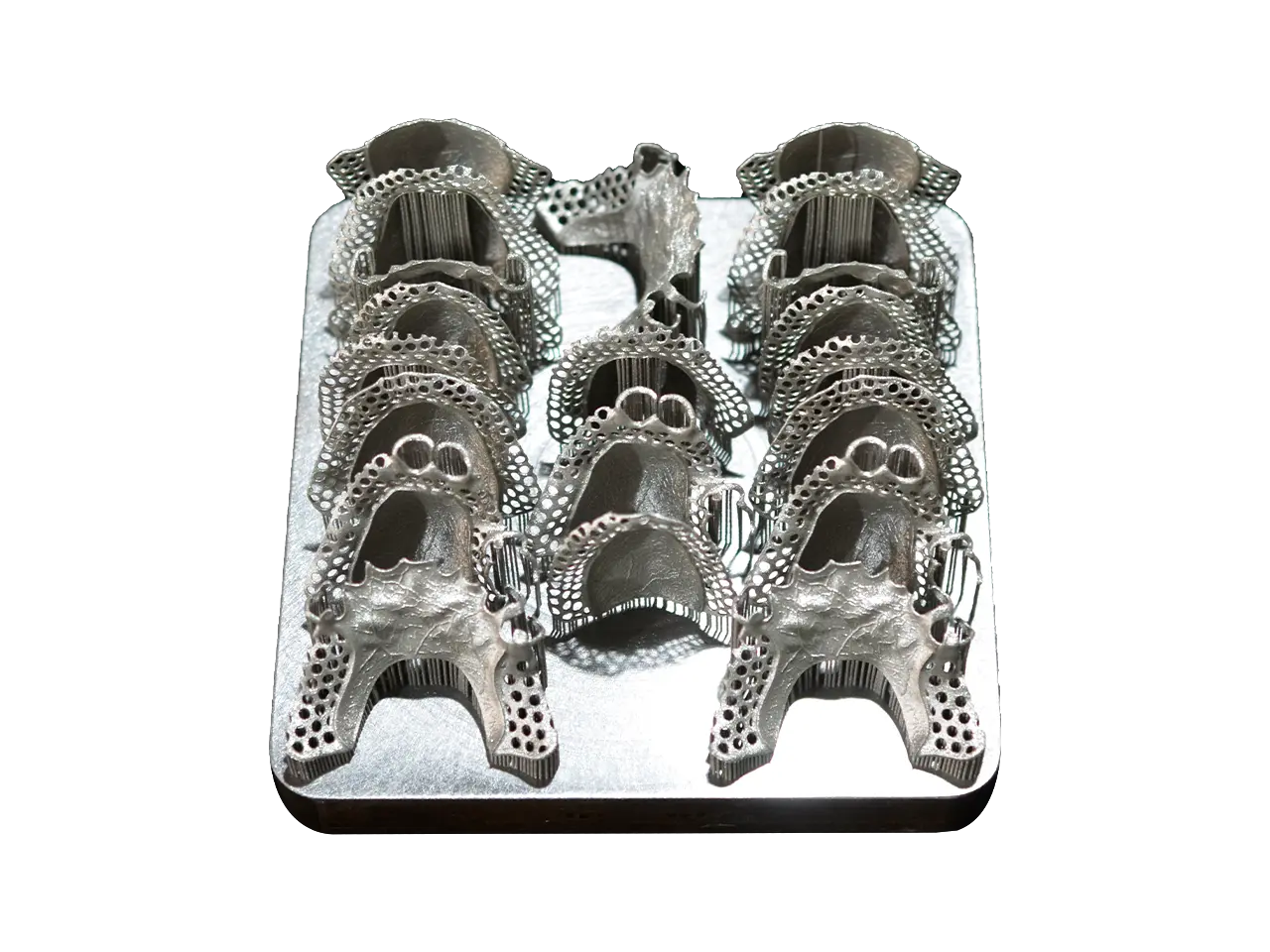

Manufacturing process: from design to assembly Bodily printing: The researchers selected the V6 model on the OpenFlexure platform and used a 3D TUOZHU X1C printer to print the body of the microscope with a black plain material. The printing parameters are adjusted on a 0.2 mm layer thickness and the filling density is 15%. Orange = LED light source, magenta = 3D printed condens, blue = 3D printed lens, green camera = CMOS Manufacture of objectives: The condenser and the objective objective are made via a 3D printing technology. The researchers used the Fusion 360 software to rethink the available business objective and printed it with a Transparent Formlabs resin on the Elegoo Mars 3 Pro printer. The height of the printing layer is defined on 10 microns, the exposure time is 9 seconds and post-processing includes cleaning and hardening, which takes 9 minutes and 15 minutes respectively.。

Assembly and commissioning: After print all the parts, the researchers joined the camera, the light source and the Raspberry Pi under a microscope and finally assembled in a fully functional device.

Test results: satisfied performance To check the performance of 3D printed microscopes, the researchers carried out several tests using standard test samples and histological samples. The test samples included colored blood smear in Gimsa and hematoxyline-mouse-colored renal cuts. The test results show that this microscope can clearly present the complex anatomical structure of unique red blood cells and renal mouse sections, reaching subcellular resolution. This result shows that 3D printed microscopes can always meet the needs of the basic medical diagnosis under the premise of the low cost.

The meaning of the low -cost microscope

Dr. Liam Rooney, a postdoctoral researcher at Strathclyde University, said: “This study opens new doors to democratized acquisition, rapid prototyping and personalized manufacturing of microscopes.

It helps not only scientists and doctors in low -income countries to obtain high -quality diagnostic tools, but also allows students to learn scientific knowledge through low -cost equipment and stimulate their interest in scientific research. “”

Conclusion

Although the 3D printed microscope has obtained satisfactory results in performance, researchers say that there is still room for improvement in the future. For example, the resolution and imaging quality can be further improved by optimizing the design and printing materials of the lenses.

In addition, with the continuous development of 3D printing technology, the manufacturing time should still be shortened and the costs can be further reduced. |