The story that used to occur in the mobile phone industry is now reconstituted in the 3D printer field.

At first glance, the price of a mobile phone is comparable to that of a 3D printer, one is a communication tool and the other is a manufacturing tool. By thinking about the history of development of the two, we can find certain similarities. However, mobile phones have now become a consumer product that everyone has, and 3D printers still have a long way to go to enter thousands of households.

The consumer quality 3D printer which we are talking about here refers mainly to 3D FDM printers (cast iron deposit molding). 3D printers. The first mobile phones are developed from bulky “big brother” to popular intelligent devices and have experienced the evolution of the interaction on the operation of the buttones on the touch screen. Consumer quality 3D printers also undergo a transformation of professional tools at home and popularization.

The first low -cost 3D printer in the world – Darwin, is from2005The Open Source REPRAP project.Around 2010The emergence of improved prusa Mendel versions, as well as Makerbot, Ultimaker, Rostock and other models triggered a 3D printing craze. However, most of the machines at the time were to be assembled and debugged by users, and materials only supported basic plastics such as PLA and ABS. In addition, the precision of the printing is low, the texture of the layer is more obvious and the operational experience is not very good.

arrive2015A company represented by Chuangxiang 3D, based on open source design, produces large -scale DIY machines at low -scale, including the Ender series, quickly occupying the world market. And in the key2022Tuozhu technology was born and launched its first product – the multi -color 3D printer in the Bambu Lab X1 series. With the Corexy structure, high -speed printing, automatic calibration controlled by AI, Lidar detection and multicolored printing, it considerably reduces the difficulty of the operation of users and quickly widens the gap with competitors similar.

Now, after more than two years of development, 3D high -quality 3D printers have fully entered the 2.0 version, and high speed, multicolored and easy to use have become the standard industry equipment.

Previously, we have mentioned Reprap, the open source community of 3D printing, and Prusa research, which grew up and grew up from Prusa Mendel, has become a distinctive banner in the open source ecosystem. Some time ago, the “condemnation” surrounding the deeper approach of Tuozhu of a deeper closed source always turned. In fact, the first models of Makerbot were also open source, but the subsequent passage to the closed source also caused a large controversy.

In fact, the open source and source game closed in the 3D printing industry is similar to competition between Android and iOS in the mobile phone industry. In the open source ecosystem, manufacturers such as Prusa research emphasize open source hardware and software (such as Prusasliner) and encourage users to make changes and secondary development. For example, many innovative features in its software, such as trees support, are motivated by the continuous iteration of software thanks to the community contribution.

Tuozhu adopts a closed system, emphasizing the “plug and play” experience and limiting material modifications. It provides a machine that users can use directly and can work without even checking the manual. Thanks to standardized software and hardware, TUOZHU considerably reduces the failure rate, but it is a big obstacle for users of practical manufacturers. Unless they choose “jailbreak”, such as the use of cracked firmware (like X1 Plus), the price is to sacrifice guarantee services.

The debate between open source and closed source is essentially a balance between user freedom and commercial control. Obviously, Tuozhu chose the path of the closed source. After all, the founder of Takuzhu comes from Dji, and Dji is the model to make drones in mass consumer goods.

Tuozhu technology – Provides the closed Apple mode out of the box

Tuozhu builds a technical ditch through its independent closed systems (such as the AMS multicolored printing system, Lidar closed loop detection). to Slice software, offering a “plug-in” just a ready-to-use high-end experience.

For example, the Lidar sensor of the Bambu Lab X1 and 43 body sensors carry out the monitoring of the leveling and fully automatic printing processes, and the technical complexity is far beyond the average of the industry. In addition, the MakerWorld Model Community of Tuozhu is very suitable for equipment, and users can directly download the predefined parameters optimized to form a closed ecosystem of “hardware + software + content”. This model reduces the operating threshold and attracts a large number of non -professional users.

It should be mentioned that competition for model platforms becomes fierce, and Makerworld (Tuozhu) and Chuangxiang Cloud (Chuangxiang) are competing for designer resources, which is similar to competition between the App Store and L ‘Android App Store.

We are very happy to see that the base of users of 3D printing extends from former engineers to “two -dimensional” amateurs, groups of manufacturers and even ordinary consumers. However, there is still a wait until a real “office revolution” of 3D printers. Despite more than a decade of education on the market, most people still consider 3D printers as “toys” or “educational tools” rather than practical production equipment. If you spend thousands of yuan to buy such a machine, users fear being able to “eat dust”.

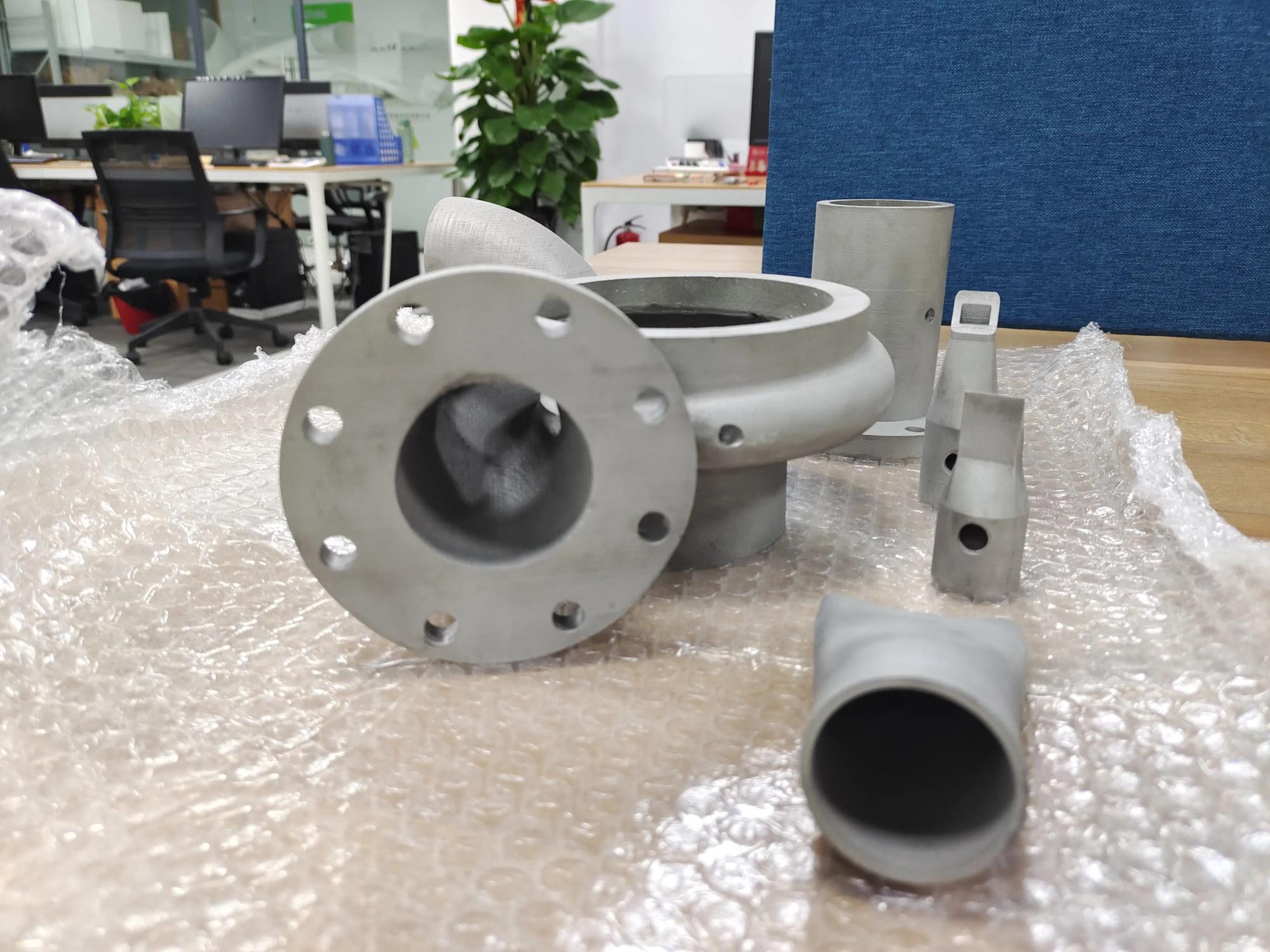

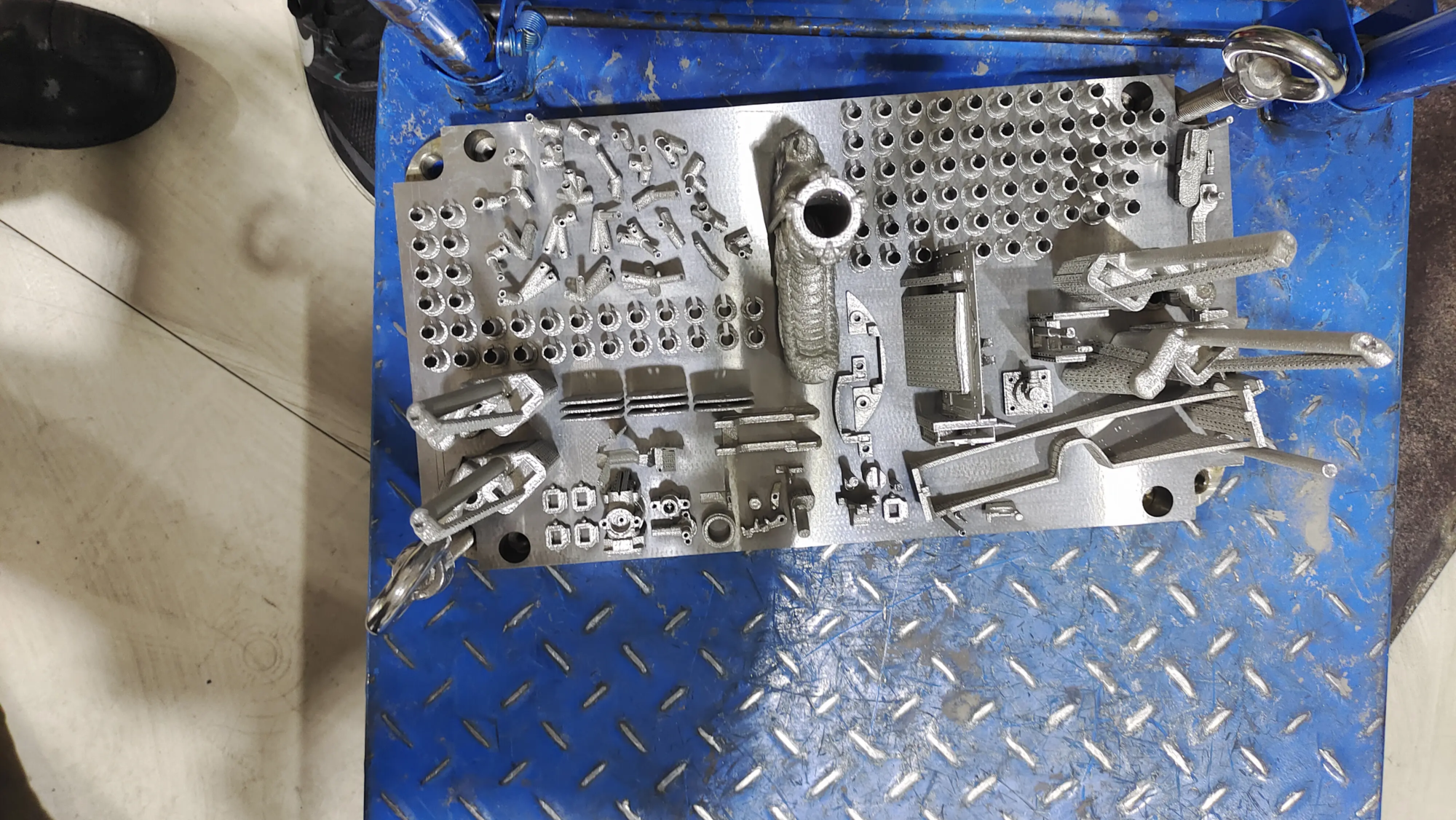

In addition, 3D printing always faces the contradiction between speed and quality, and finished products often have problems such as obvious and not smooth diapers. Whether in terms of printing or precision time, 3D printing always has a considerable difference compared to traditional processes such as injection molding. Ordinary 3D printers are mainly based on plastics such as PLA and ABS, and the singularity of materials also limits its expansion in home application scenarios. The most critical point is the design capacities of the model.

However, according to official statistics from the General Customs Administration, the number of consuming quality 3D printers exported in 2024 reached 3.76 million, which set a record of the year. We can say that the current 3D printing of consumer quality is a critical point of “spending geek toys to domestic tools”, and its popularity process is similar to that of the first stages of smartphones.

Despite multiple challenges such as technology, costs and user awareness, reducing design thresholds by AI + 3D printing, expansion of practical scenarios for low -cost and high performance materials, and the ‘Technical iteration of the equipment itself can be able to reach the “house” in the next 10 to 20 years.