By reading this article, we can not only understand the strategic layout and thought of the United States in the field of additive manufacturing, but also reflect on the opportunities and future challenges of the additive manufacturing industry of the China. The article offers an inspiring perspective, which is of great reference value for the way we take the initiative in global competition and which is worth reading.

Dear President Trump and administration members:

The United States faced a critical moment. Additive manufacturing (AM) is a transformative technology that will redefine the future of global manufacturing and national security. However, this technology may move away from us. As an additive manufacturing inventor, the United States should direct its sustainable development and large application. Instead, if we do not make decisive measures, we can repeat the same errors, give the leadership to China and pay a high price, as we have done in the field of solar panels.

China is aggressive in order to gain the domination of the world market for additive manufacturing. According to Am Research, the additive manufacturing market of China is “one of the manufacturing markets additive to the fastest growth in the world, and perhaps even the fastest … This is largely due to government’s incentive policies “. It turns out that the support of the Chinese government has caused a number of competitive equipment that have drawn attention not only in China but also on the international market. If China is authorized to dominate this market, the United States will not only be faced with the loss of well-paid manufacturing jobs, but will also endanger national security. The Ministry of Defense (DOD) clearly said that additive manufacturing is crucial to building resilient and flexible supply chains, as well as to support the production on demand for key defense applications.

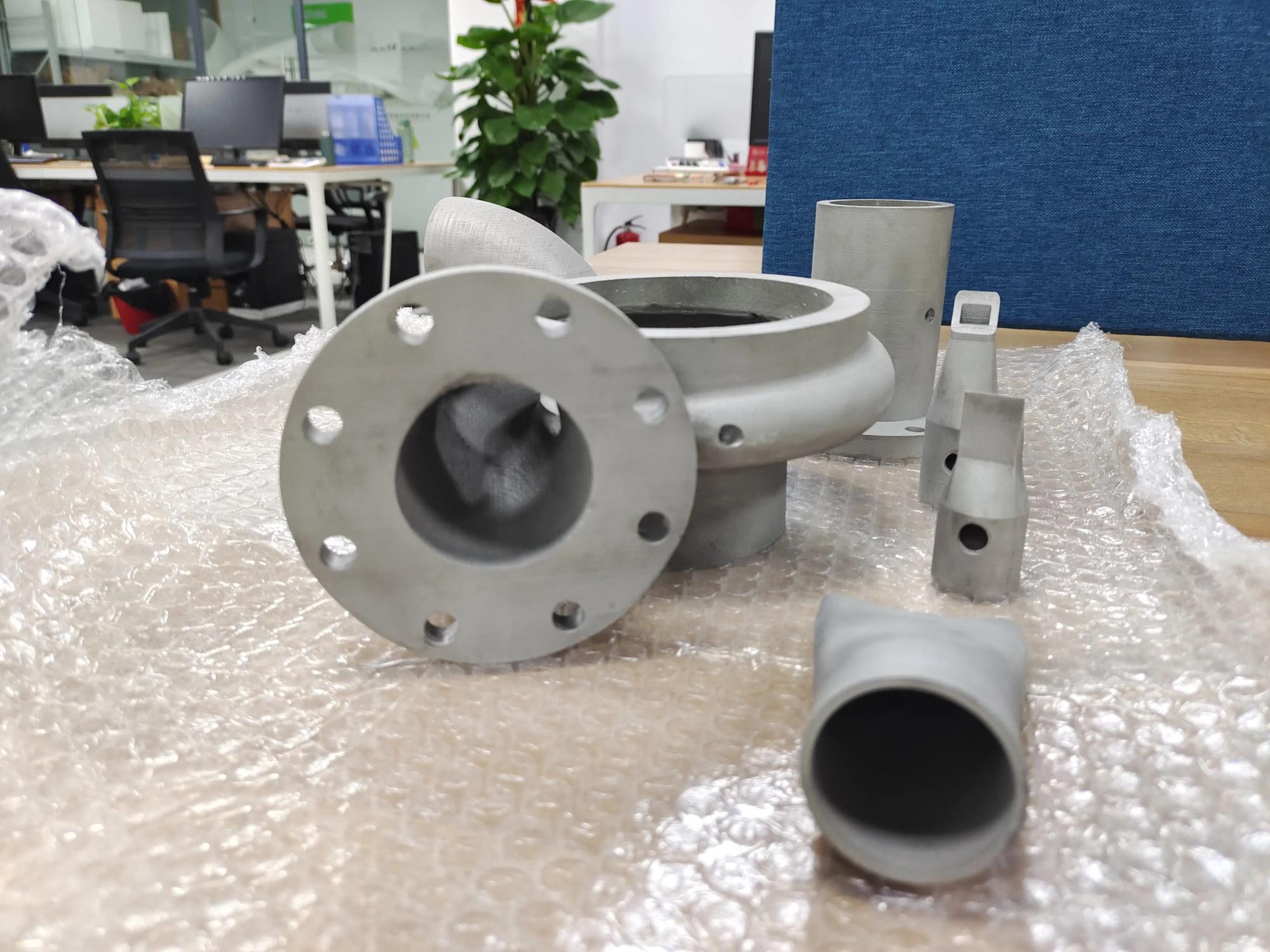

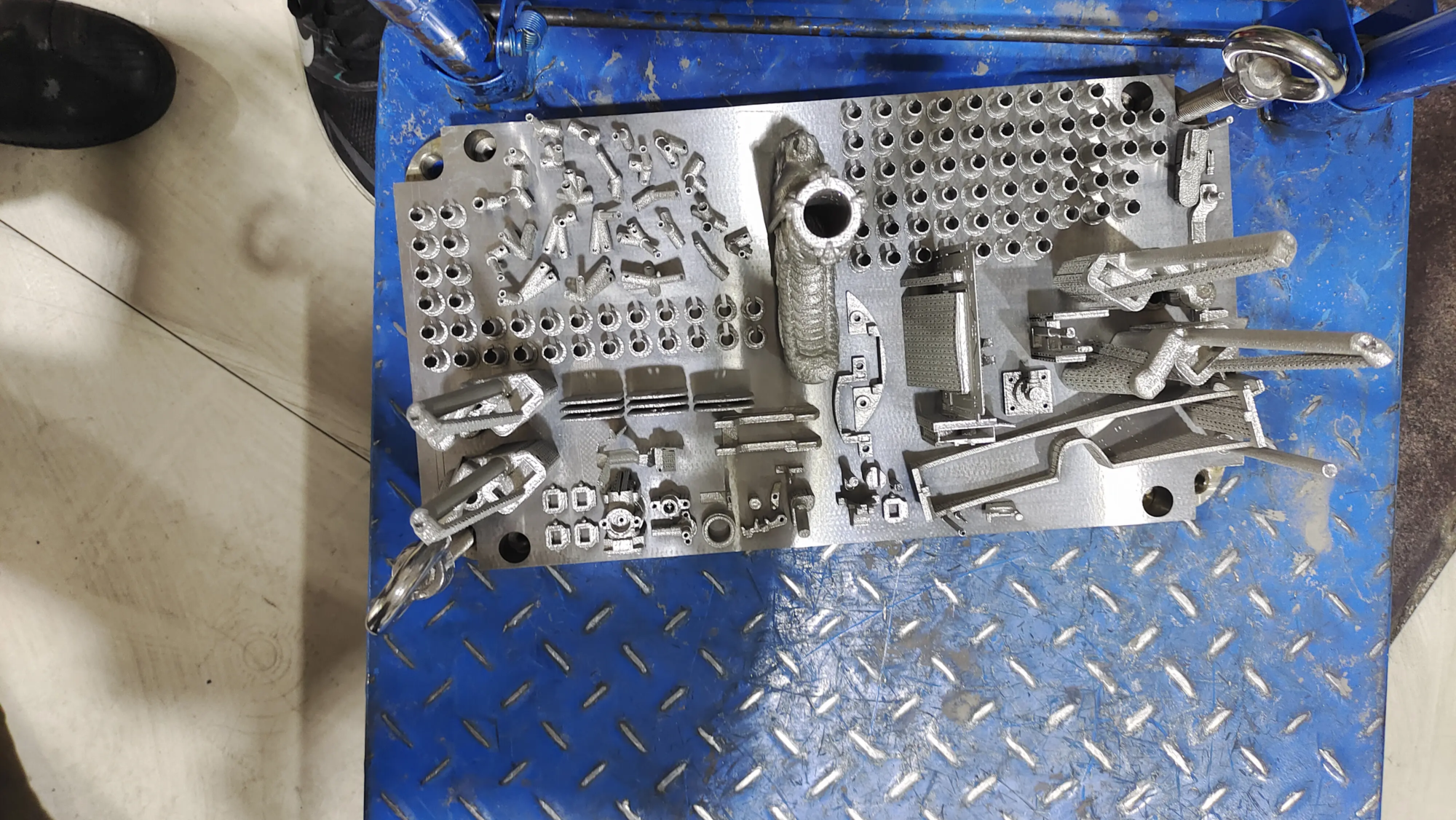

Unlike traditional manufacturing methods, additive manufacturing can optimize production efficiency. Traditional manufacturing generally requires waste materials through large quantities of rough machining operations, or to rely on expensive tools for casting and forging. Additive manufacturing is particularly important for industries, from consumer goods to defense, which attach great importance to innovation, speed and flexibility of products. For the United States, additive manufacturing is a key engine to maintain military advantages, improve infrastructure resilience and promote innovation of commercial products.

Prices alone are not enough to meet the challenges

Although prices are an important tool for American trade policy, they are not enough to ensure the future development of the United States in additive manufacturing. Prices alone cannot build a strong industrial infrastructure. We must adopt the following several parts approaches, including strategic investment, simplification of certification processes and the development of policies that promote innovation and improve the competitiveness of American companies.

Political recommendations to ensure American leadership in the AM field

While the Ministry of Defense increases MA spending, these efforts require more coordination and attention to maximize their impact. Sporadic support for American companies AM is not enough to stimulate the systemic change necessary for our obsolete manufacturing ecosystem. To protect and strengthen the American position in the field of additive manufacturing, we recommend that the government take the following measures:

1. Establish an AM national adoption working group

Establish a working group Internestitutions to promote the adoption by the government of additive manufacturing components. By rewarding the first adopters, they are encouraged to take reasonable risks and take advantage of the flexibility in the production of additive manufacturing. The working group should also promote the sharing of experience between agencies and pave the way for a general acceptance of additive manufacturing.

2. Offer tax advantages for AM investment

Tax credits are provided to companies that invest in the development or use of additive manufacturing components. This decision will stimulate innovation in the private sector, will attract the necessary funding and allow the United States to stay ahead of the field.

3. Support R&D funding for advanced AM technologies

Develop federal funding to study the materials, processes and commercial expansion of additive manufacturing to obtain technological breakthroughs and maintain competitive advantages.

4. Simplify the AM parts supply and certification process

Simplify the purchase examination process and qualification for AM parts in national defense and other areas to accelerate the application of key technologies.

5. Cultivate professional and technical talents AM

Thanks to scholarships and incentives, targeted training programs are implemented in universities and vocational schools to prepare for the new generation of well -remunerated additive manufacturing stations.

6. impose and apply prices to Chinese AM products

The imposition of prices on the additive manufacturing equipment manufactured in China and its parts produced is a necessary means to ensure a level playground. It is recommended to modify the coordinated price calendar (HTS) to allow more precise control of critical supply chains. By taking specific measures based on different additive manufacturing methods, governments can balance unfair playing conditions while reducing the risk of excessive intervention.

Consequences of inaction

If we choose to wait and see, it will be a huge price. The domination of China in the field of additive manufacturing will lead to:

– loss of well-paid manufacturing jobs in the United States;

– weakening of competitive advantages in defense and business;

– dependence on the China supply chain damages economic and technological sovereignty.

It is only in active investment, innovative policies and a unified national strategy that the United States can ensure world leadership of additive manufacturing.

Call for action

At Seurat Technologies, we are committed to making evolution, evolutionary, profitable and transformative additive manufacturing for all horizons. Our patented area Area Printing® represents a huge jump in manufacturing capacity. However, we cannot achieve these objectives alone. To achieve this vision, we need the strong support of political decision -makers, leaders in industry and stakeholders to build the necessary infrastructure, talent and innovation channels.

Mr. President and the leaders of the government, our opportunity is right before us and is the time to act. Let us work together to ensure that additive manufacturing becomes the cornerstone of the American industrial force and a model of world leadership, rather than another key area which is exceeded by China.

I would like to express my gratitude to you,

James Demuth

Co-founder, co-inventor and CEO

Seurat Technologies, Inc.

Founded in 2015, Seurat Technologies is based in Sunnyvale, California, the United States. aims to revolutionize the manufacturing industry of metallic additives. So far, the company has raised around $ 300 million thanks to several financing cycles. The main investors include many well-known venture capital companies such as True Ventures, DCVC and Capricorn Investment Group.