In the last 2024, Yichi technology has successfully sold more than 80 3D printing systems, 90% of which are sold to the domestic market and 10% are exported to Canada, Ukraine, Russia and Thailand. In 2025. According to the Resource Library, the company is preparing CE certification for the M150INNO and M400Pro series, and plans to launch new jet printers glued in metal – M200eco and M400Plus in March 2025.

As a business with more than ten years of experience in metal jet-jet technology, Yichuan technology continues to improve its technology in order to fill the shortcomings of this market for Western manufacturers. In recent years, Western companies such as Desktop Metal, Exempt, Markforged, GE and HP have failed to obtain expected market share in the field of metal connection technology.

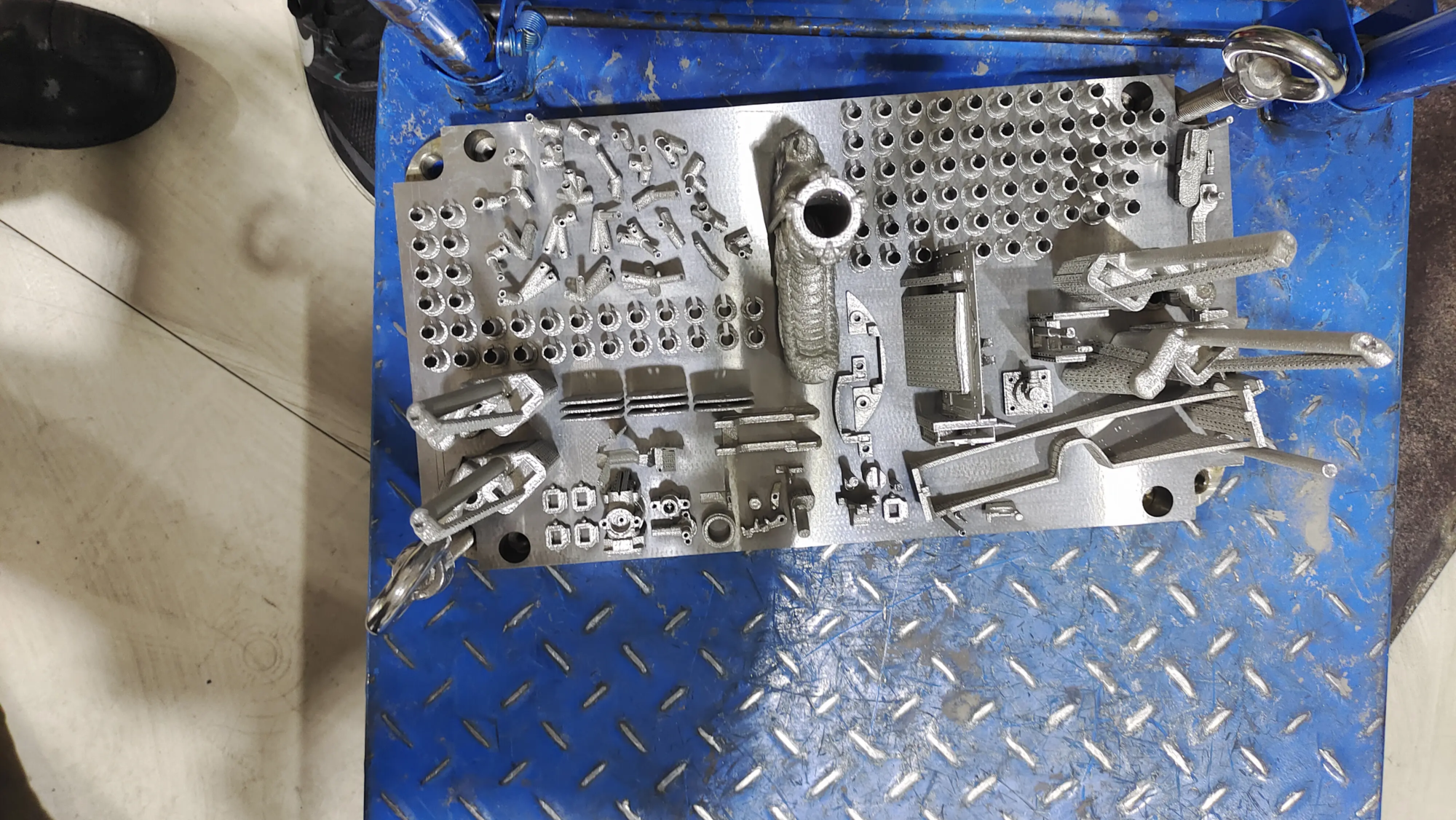

To take up this challenge, Yichi technology has continued to improve its technology and launched several products that have drawn the attention of the industry. In 2023, the company launched the M400Pro, characterized by high speed and precision. Subsequently, the launch of M550MAX improved production efficiency, achieving significant growth in exit capacities compared to generations of previous products. In 2024, Yichuan’s technology launched the M150INNO, a printer designed for the experimental development of alloys and geometric tests, reducing material waste while promoting technological innovation.

M200ECO: a profitable metal print solution

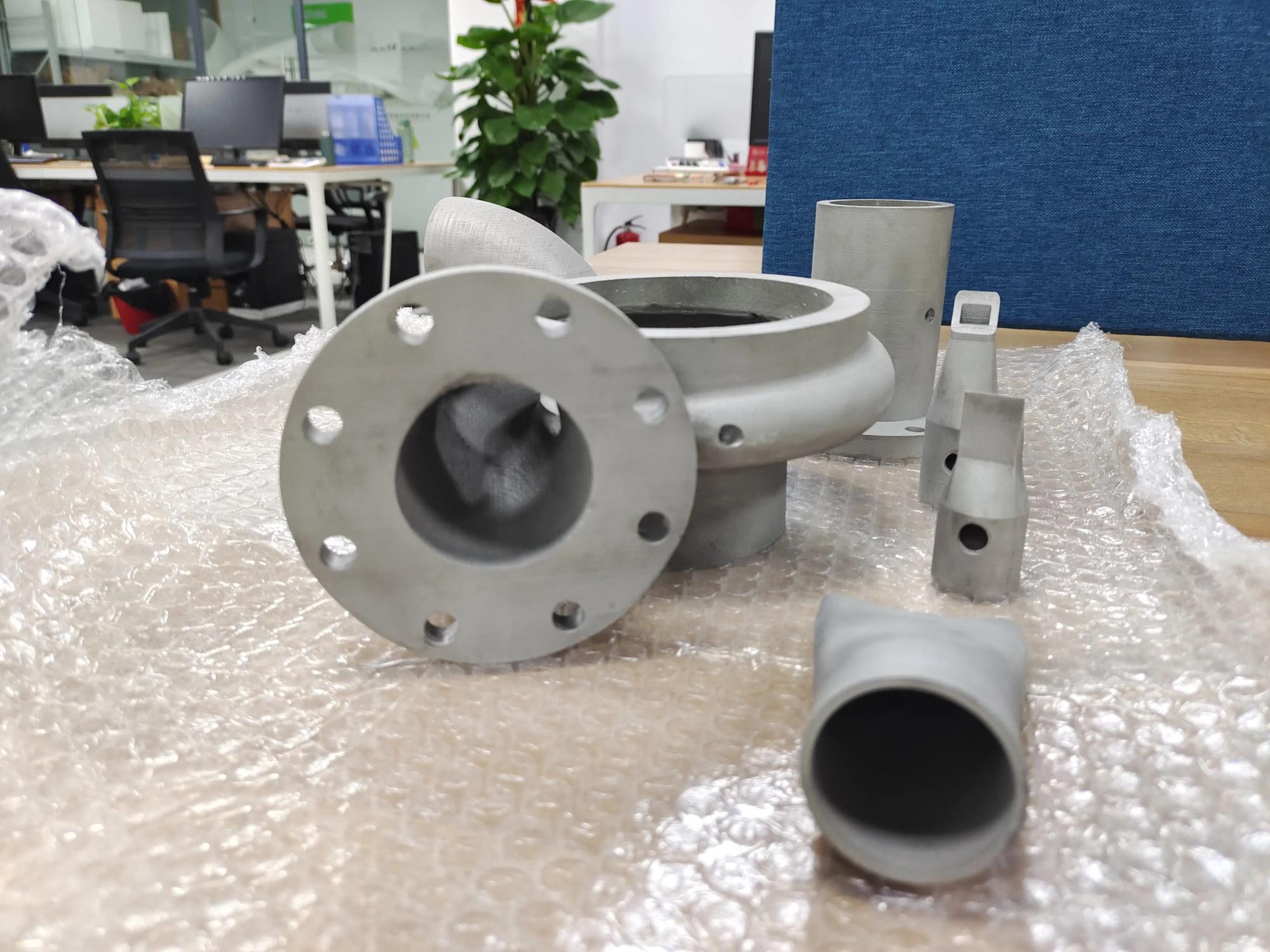

In order to meet market demand for more economical and practical metal printing solutions, Yichuan technology has launched the M200ECO. This device is particularly suitable for small and medium -sized businesses and is capable of effectively printing the parts traditionally produced by the molding by metal injection (MIM).

The M200ECO has a compact design that is suitable for working environments with a limited space and provides print precision similar to the Pro series. Its balance of costs, mobility and precision makes it a viable option for low -volume production, especially for users sensitive to costs.

M400Plus: optimized performance and material control

The M400Plus released with the M200ECO is an improved version launched by Yizhi technology based on the design concept of the Pro and Max series. The equipment adopts an entirely closed frame to improve safety and optimize the powder treatment system to reduce environmental pollution.

The M400PLUS is equipped with a lifting mechanism of the Axis Z of precision and an improvement of the distribution and powder coating systems, which not only improves the density of the materials but also effectively reduces the diffusion of the dust. In addition, the equipment also sealed automatic doors and precise motion control systems to ensure a more stable and coherent printing effect.

M400Plus technical specifications:

- Printing volume: 20 liters

- Print box size: 400 x 250 x 200 mm

- Maximum print speed: 1340 cubic centimeters / hour

- Layer thickness beach: 30 to 100 adjustable microns

- Parties accuracy: ± 0.05 mm

The prospects of metal connection technology

Although some Western companies are faced with certain challenges in promoting metal connection jet technology for the production of high speed parts, this trend gradually changes. The recent HP partnership with the Indian Society of Metal Injection Injection has developed, and the deployment of multiple systems also progresses. Meanwhile, companies such as Desktop Metal and Markforged are working to solve financial problems and should continue to promote their technology. Thanks to the publication of M200eco and M400Plus, Yizhi technology has gradually become a company in the field of metal connection jets, providing solutions to many companies.

These innovations focus on improving printing efficiency, production scale and environmental sustainability, and promote additional application of the manufacturing technology for metal additives. With the improvement of precision, the optimization of the use of materials and the increased flexibility of production, Yizhi technology gradually becomes an important participant in the field of industrial 3D printing.