Xingsheng Precision: A new member of the 3D micro-nano printing.

The 3D micro-nano printing is an advanced manufacturing technology which can directly create complex three-dimensional structures on micron scales (µm) in nano (nm). It combines the principle of layer for layer by layer of traditional 3D printing with the high precision requirements of the treatment of micro-annano, prevents the limits of traditional manufacturing technology in resolution and structural complexity, and is widely used in microelectronics , biomedical, photonics, micro -mechanical and electromechanical industries.

When Nanoscribe updates the limit of 3D printing manufacturing with a nanometric scale, when Yunyao Shenwei pushes metal micropritis to aerospace level applications, when Nano 3D uses two -photon polymerization to redefine optics – The 3D micro -nano printing industry is astounding, the speed is redding the boom -. In this improved precision manufacturing battle, the differentiation of technological routes becomes more and more important: the photocurage camp contributes to medical and general public electronics, metal microprimony is focused on high -end equipment and technology Two photon polymerization deepens photoelectric fusion.

However, a fundamental challenge is still in advance in the industry:How to carry out the transition of a technological breakthrough unique to the integration of the transverse and multi-material system in the manufacture of micro-nano?

The path of Xingsheng Precision to break the damage

In Jiangmen, Guangdong, a family withMake precision manufacturing to simpler and more efficient research innovation“For the positioned 3D print start, he gave his own solution to the problem.Jiangmen Xingsheng Precision Manufacturing Co., Ltd.(hereinafter referred to: “Xingsheng Precision”) did not choose to fight with the main manufacturers in a single dimension of precision, but rather built a systematic solution of the Trinity “equipment-material”.

Make the closed loop of the Micro-Nano printing industry

In terms of equipment, the micro-scale surface scanning system developed independently of the company achieves 1 μm positioning precision. The system can print a layer thickness of 5-30 μm.

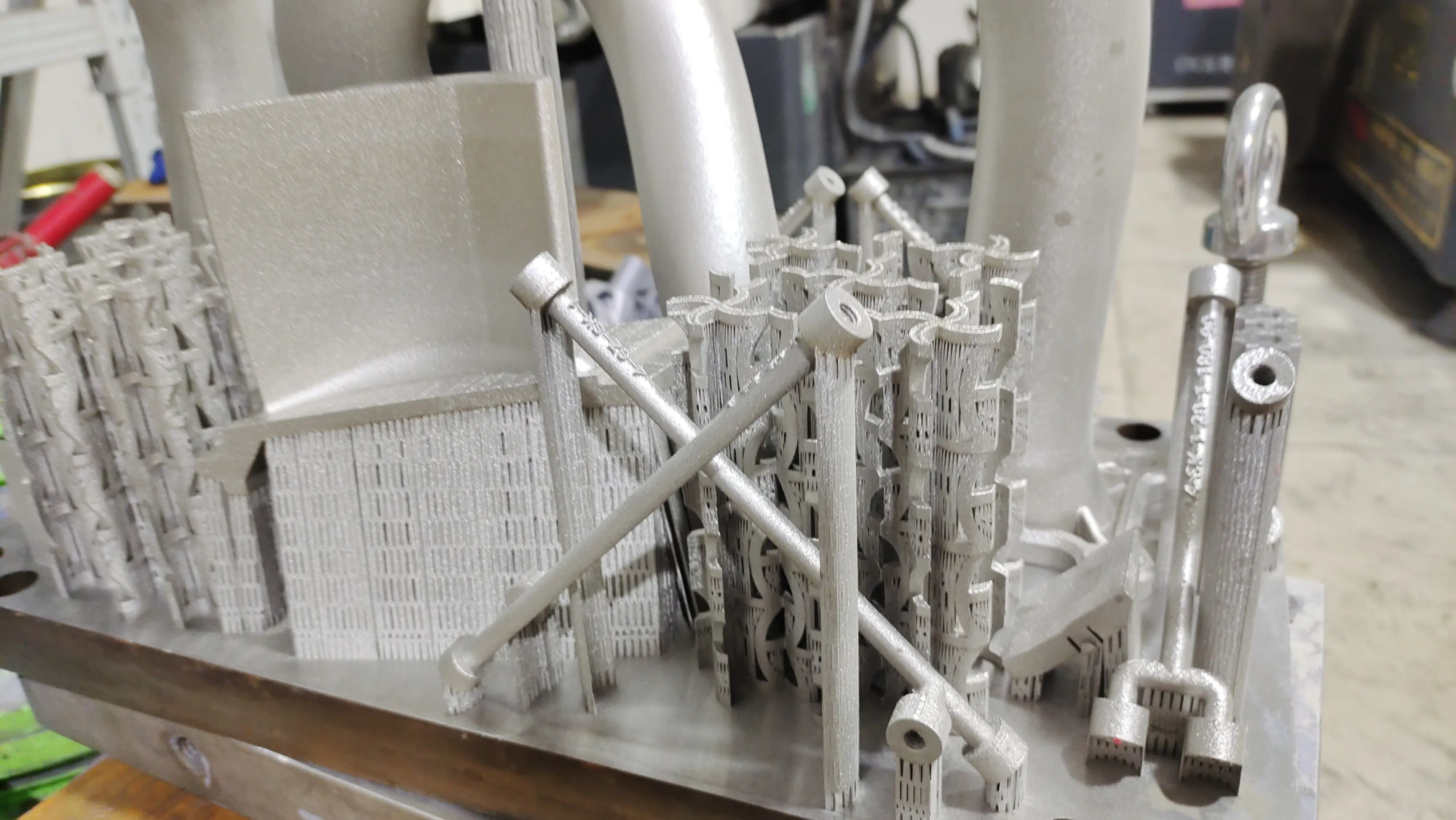

The following is the display of Xingsheng Precision’s reference application application scenarios.

1. Precision medical applications

2. Industrial micractions applications

1. Intelligent elastomer materials: Innovate elasticity and remodeling comfort

The elastic material photocious with two components is reticulated oriented through molecular chain segments to reach “the contradictory performance unit” of the traction resistance of 20 MPa and an extension> 400% of rupture, and the resistance to the Tear resistance is> 20 kN / m. 200,000 dynamic fatigue tests have been passed, can beIntegrated shoes / shoes / shoes and other shoe industries,Bicycle stools / protective equipment and other sports equipment,Headphones / protective equipment and other safety devicesPillows / mattresses and other daily necessitiesCarry out large -scale applications. (LCD and DLP printers can be used)

2. Multiplate nylon material: strong resistance to flue and wide compatibility

The high spherical PA12 powder has a breakthrough in the realization of infinite recycling; The resistance to the traction of the material exceeds 45 MPa and the rate of elongation rupture reaches more than 30%. It is suitable for consumer equipment such as EOS, Easyga 3D and Huashu Hi-Tech, and the PA black material is optimized by the absorption of the laser, which can be suitable for fiber laser equipment.

The powder particles are as round as the football balloons, and the powder has good fluidity, which makes not only the smooth printing surface, but also improves printing details. And long -term reuse will not cause orange peel. Currently, there are many materials such as White PA, PA + GF, PA + Powder, Black PA, etc.

If you are interested in xingsheng accuracy, you are looking for micro-nano 3D print suppliers, or you need elastic materials or special nylon, you canContact Mr. Yuan: 15815507326(Same number on WeChat).

About the Xingsheng precision

Jiangmen Xingsheng Precision Manufacturing Co., Ltd. is a company focused on 3D micro-nano printing technology, covering research and development, production and manufacturing and sales of equipment and materials. Based on micro-scale surface scanning technology, the company provides high-precision 3D printing equipment and technical services to help customers quickly manufacture micro-nano structures in three complex dimensions and combine different materials And process to obtain effective and low -cost massive production costs terminal products.

As a high precision manufacturing company, Xingsheng Precision has established cooperative relations with hundreds of large companies such as Huawei, Hikvision and Mini-Invasive Medical. Connectors and other fields. At the same time, society has also cooperated with hundreds of scientific research institutes, including the University of Beijing, Tsinghua University, the University of Zhejiang, the University of Shanghai Jiaotong, the Fudan University, The Sun Yat-Sen University, the University of Hong Kong, Hong Kong Polytechnic University, Institute of Institute of Institute of Microelectronics, Harbin Institute of Technology, etc., help universities and research institutions to quickly promote advanced innovative research.