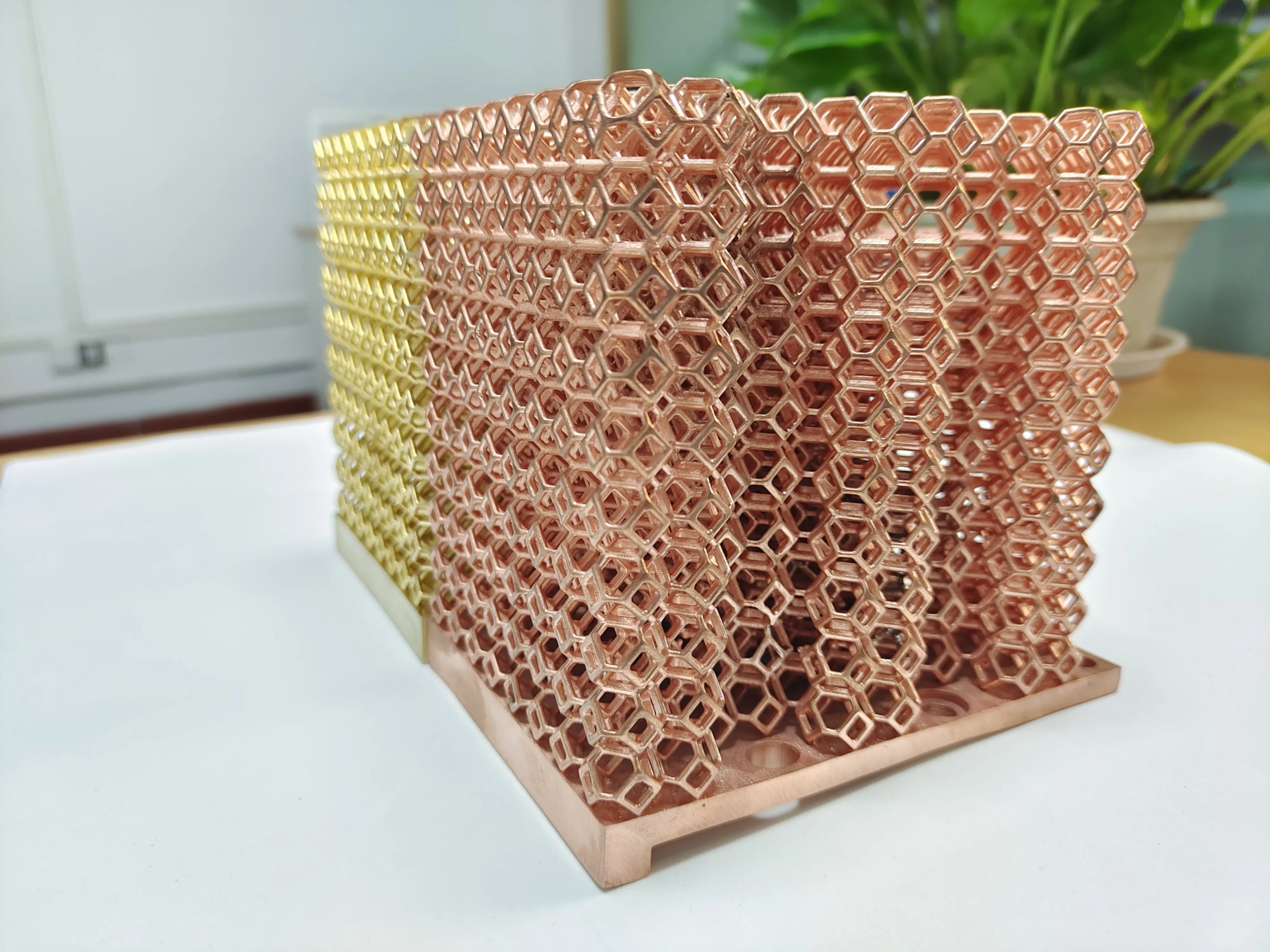

Congratulations to Ningbo Shangcai 3D for successfully completing A and A+ round financing of nearly 100 million yuan with its advanced titanium alloy production technology. It plans to invest hundreds of millions of yuan in the future to achieve a powder production capacity of 10,000 tons. aiming to become a leader in the field of titanium alloy powder. Round A was invested exclusively by Yanfa Fund, while Round A+ was jointly led by Fosun Capital and Yunze Capital, with Ningbo Angel Fund following the investment.This financing will mainly be used to build a new production base and expand the technology research and development team to promote the company’s further development. at present,Series B funding has also been officially launched. Shangcai 3D was established in 2018 and focuses on the titanium alloy powder business. Its technical strength and product indicators have reached the advanced level internationally, and the annual growth rate of market and production capacity exceeds 100%.The Company’s products cover multiple categories such as TC4, TA15, TA1, TA2, TC11, Ti2AlNb, 4N5Ti, etc., with different particle sizes, and can be used in additive manufacturing, press sintering, die casting. injection, hot isostatic pressing, laser repair. , hot and cold spraying, etc. Technology, widely used in aviation, aerospace, medical, consumer electronics, semiconductor, automobiles, sports equipment and other fields. The company’s core team has been engaged in the development of titanium alloy powder technology since 2014 and has accumulated rich experience in materials, processes and equipment. It is one of the important promoters of the development and application of high-quality spherical titanium alloy powder. and additive manufacturing technology in China.With EIGA technology as the core, Shangcai 3D has a vertical layout around the titanium industrial chain, covering titanium alloy material research and development, smelting processes, HDH spraying processes and other technology developments . It has built an R&D center and several production bases, striving hard. to build a production capacity of 10,000 tons, directly aiming at the leading position in China and the global titanium alloy powder industry. Shangcai 3D has a first-class R&D process team, and the entire production process and host equipment have independent intellectual property rights. The self-developed multi-control fusion atomization system greatly improves production efficiency, and the powder surface fine shaping technology greatly optimizes the powder quality.The team has the ability to develop materials and can provide customized products and services for various industries. It moves away from the current industry situation by relying on equipment manufacturers to provide technical solutions, realizes a closed loop of equipment optimization and process upgrades, built. higher technical barriers and significantly reduces future production capacity. In 2024, the 2,000-ton production base of Shangcai 3D in Panzhihua, Sichuan was gradually put into operation. The base covers an area of 12,000 square meters and has a production capacity of more than 1,000 tons. The Company will fully exploit Panzhihua’s advantages in titanium resources and hydropower, continue to improve technology and production capacity, and enhance industry competitiveness. In addition, the company also actively participates in the construction of the local vanadium and titanium industrial chain, promotes coordinated upstream and downstream development, and is committed to providing high-quality metal titanium powder products to partners in downstream, thereby ensuring efficient operation of the supply chain and continuous optimization of product quality, and assistance in technological innovation and service upgrading. The high-quality development of powder materials industry contributes to industrial upgrading and economic prosperity.

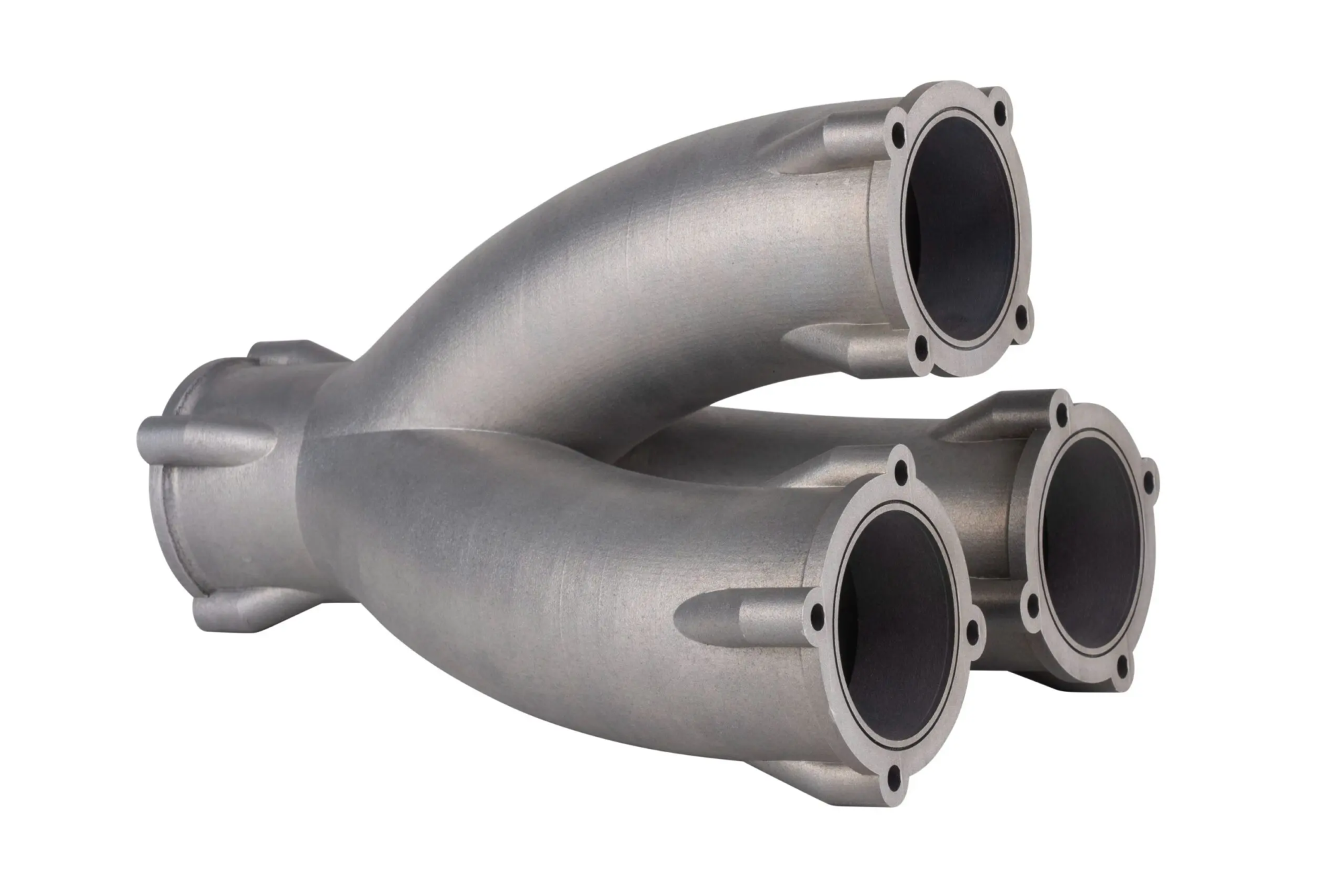

Market Overview Titanium metal has abundant reserves and excellent performance, and market demand continues to grow rapidly. As a strategic metal in the 21st century, titanium alloy has the characteristics of low density, high strength, corrosion resistance and non-magnetism. It is the first choice for lightweight and high strength materials in many industrial fields. national defense, aerospace, medical, automotive, etc. The application area has broad prospects. China’s ilmenite reserves are the largest in the world. In 2023, China’s titanium ore production will reach about 7.25 million tons, an increase of about 10% year-on-year. In the same year, the global titanium sponge production capacity reached 444,000 tons, maintaining a growth trend. China’s cumulative production of titanium sponges was 215,400 tons, accounting for 48% of the world’s production capacity, a year-on-year increase of 21.72%. The total amount of titanium materials processed nationwide is about 170,000 tons, an increase of about 12.5%, and the total production value is about 135 billion yuan. However, traditional titanium alloy processing technology faces many challenges. The difficulty of machining, significant wastage of materials, and high cost limit its wide application, and there is an urgent need for new alternative processes.The emergence of 3D printing technology has brought new solutions to the processing of titanium alloys. It can effectively solve the problems of traditional processes and has the advantages of free design, complex structure casting, high material utilization, excellent mechanical properties, high casting efficiency and low cost, gradually becomes a new trend in the development of titanium industry. In recent years, the demand for titanium alloy spherical printing has increased steadily. The market application space is currently 1,000 tons and growing rapidly at 50% per year. The market size is expected to exceed 15 billion yuan. the following ten years, with a demand of almost 20,000 tonnes. Titanium alloy powder is widely used in aerospace field. Meanwhile, due to its hardness and weight characteristics, it is also expected to be more widely used in the field of consumer electronics, including smartphones, wearable devices, robots, etc. . Titanium alloy powder injection molding technology is suitable for mass production of small and special-shaped parts, which can reduce production costs by about 30% and increase production efficiency by more by 50%. This technology is currently in a critical breakthrough stage. With the improvement in market knowledge and technological maturity, the market demand for spherical powder will increase significantly over the next 2-3 years. Over the past decade, the market size of titanium and its spherical powder alloys has continued to increase. With the large-scale industrial application of related technologies in many fields, the Chinese market is expected to grow exponentially in the past two years. the largest spherical titanium alloy powder application market. With the development of 3D printing technology, the terminal application fields of titanium alloy powder continue to expand, and the market size is growing rapidly. The additive manufacturing industry has entered the growth stage from its initial stage, and the general trend shows rapid growth. Additive manufacturing revenue is expected to reach $29.8 billion by 2025, with a compound annual growth rate of 18.24% from 2021 to 2025; they are expected to reach $85.3 billion by 2030, with compound annual growth; rate of 23.41% from 2025 to 2030. . Source: Farsoon Hi-Tech Prospectus In the field of aerospace and aviation, with the demand for increasing the quantity and quality of military aircraft and the vast space reserved for the aerospace aftermarket, additive manufacturing already has a basis of application.. The properties of missile consumables are adapted to the characteristics of the process. Titanium alloy powder materials are widely used in this field, such as manufacturing engine parts, turbine blades, fuselage structures, propellers, etc., accounting for more than 50% of production . use of titanium alloy powder materials. In the field of medical devices, the global market capacity has doubled between 2001 and 2021, and the market share of orthopedic medical devices is large.Titanium alloy powder materials are ideal implant materials due to their excellent properties. 3D printing can meet personalized treatment needs, reduce costs and promote the popularity of titanium alloy implants.

In the field of consumer electronics, the market is huge and is poised for explosive growth.Companies such as Apple and Huawei have adopted titanium alloys to manufacture products, boosting industrial applications. In the future, titanium alloys will play a more critical role in market segments such as smartphones, smart wearable devices and humanoid robots. exceed 10,000 tonnes, placing itself alongside the aerospace industry. In addition, titanium alloys are also used in the field of automobile parts, especially in luxury cars and sports cars. They have great potential in terms of lightness and safety of new energy vehicles.

|