Source | 3dnatives

Author | Madeleine P.

Compile | Resource Library

According to data, the global automotive 3D printing market will reach $4.7 billion in 2023 and is expected to grow at an average annual growth rate of 14.2% by 2032. This growth is mainly driven by demand growing number of personalized vehicles. So how is 3D printing used in the automotive industry? What are its advantages?

To delve deeper into these questions, we’ll focus on European automakers using 3D printing technology and learn about the applications these brands use to produce finished parts, create working prototypes, custom tools, or other unique items. Next, we will list these companies’ 3D printing projects by country/region.

Germany

The German automotive industry is globally known for its high quality and innovation capabilities, and 3D printing technology has a deep history in the country. Well-known brands such as BMW and Volkswagen have been deeply involved in the field of 3D printing for 20 to 30 years. Nowadays, major automobile brands such as Porsche, Audi, Mercedes-Benz and Opel have also entered the field of 3D printing and established exclusive 3D printing centers and R&D departments.

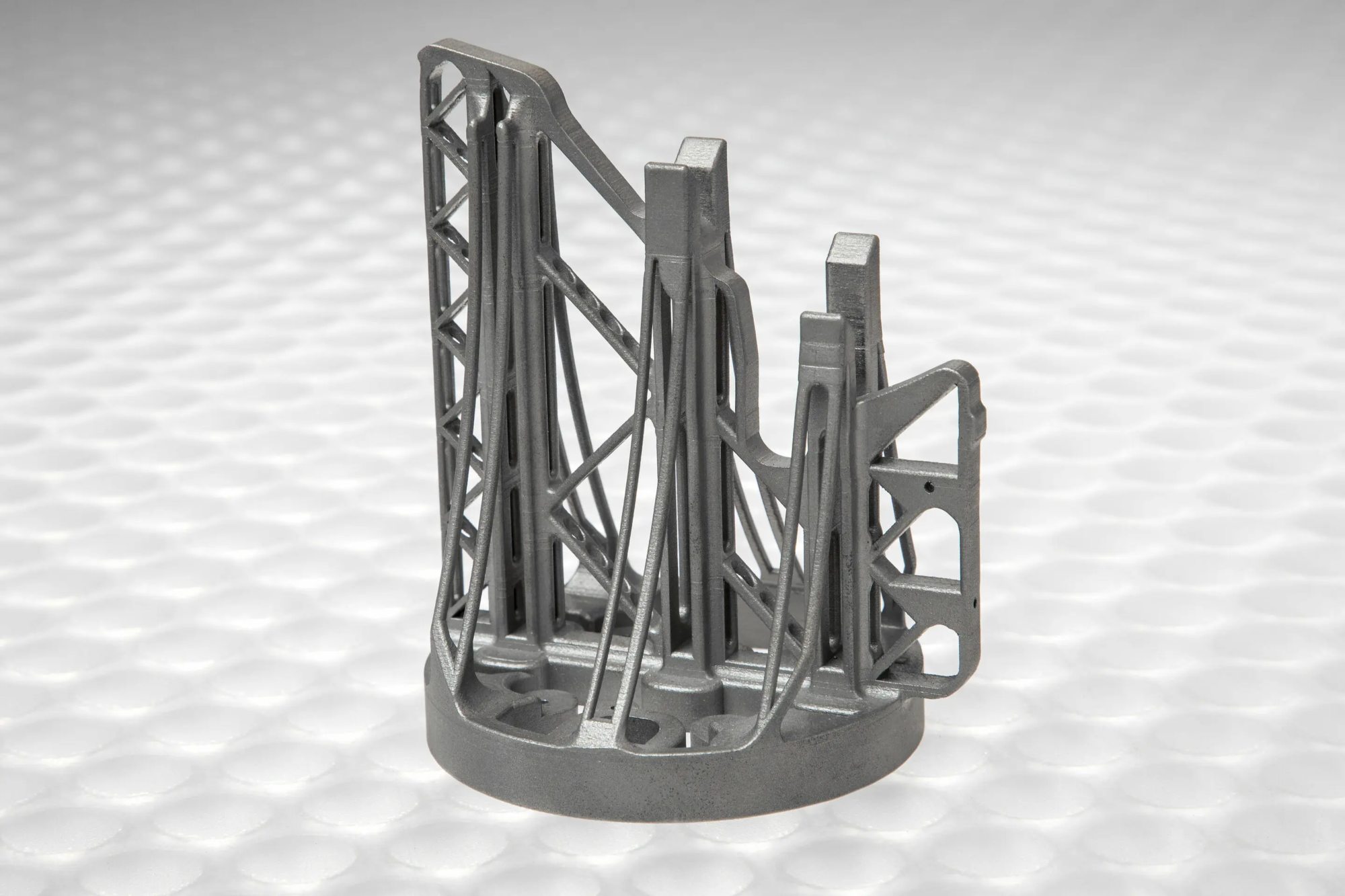

3D printing plays a key role throughout the production chain, from the development of classic models to assembly and restoration. Currently, more and more automobile parts (such as body and transmission parts) and interior parts are manufactured by 3D printing.

To meet various manufacturing needs, German manufacturers use various 3D printing technologies and materials. For example, Porsche used laser powder bed fusion (LPBF) technology to manufacture the engine housing in 2020 and optimized the topology with solutions from SLM Solutions, significantly reducing the weight of the parts.

BMW uses technologies such as SLS, large-scale printing and, more recently, metal arc additive manufacturing (WAAM) throughout its production chain. In 2023, the BMW center in Oberschleißheim produced more than 300,000 parts via additive manufacturing.

Furthermore, Volkswagen mainly focuses on metal 3D printing at its Wolfsburg factory and presented FDM technology and its application advantages to students at the Emden campus. Meanwhile, Mercedes-Benz mainly uses 3D printing for maintenance services, establishing a mobile 3D printing center equipped with digital twin technology to locally produce spare parts for its buses (Daimler trucks and buses).

France

In France, brands such as Renault, Alpine, Peugeot and Bugatti have already integrated additive manufacturing technology into their daily production. Due to different brand positioning, each group also focuses on 3D printing applications. For example, Bugatti is working to reduce the weight of supercar parts using 3D printing to further improve vehicle performance.

The brand recently designed a chassis made using metal 3D printing technology, reducing suspension weight by 45%; it also used laser powder bed fusion (LPBF) technology to create the world’s largest 3D printed titanium alloy brake caliper.

Renault focuses on internalizing the application of 3D printing technology and has established a 3D printing center in Flins that integrates FDM, multi-jet fusion (MJF) and post-processing technologies. The manufacturer produces both functional prototypes and finished printed parts, such as customizable elements for car interiors or the interior mirror shells of the Alpine A110 R, limited to 900 examples.

Peugeot is cooperating with a number of service providers to use additive manufacturing to design certain automotive parts and is investing in rapid prototyping.

Spain

A few years ago, 3D printing was relatively underdeveloped in the Spanish automotive industry. But today, additive manufacturing is widely used in the production of components in the Spanish automotive industry. According to a report by the Spanish National Association of Automotive Parts Manufacturers (Sernauto), Spain is the fourth largest producer of automotive parts in Europe, with more than 1,000 companies in related sectors. Brands such as SEAT, CUPRA and LIUX are now using 3D printing technology in their production processes.

As part of the Volkswagen Group, SEAT and CUPRA use various 3D printing technologies in their additive manufacturing centers, such as MJF, SLS, FDM and PolyJet. 80% of SEAT’s additive manufacturing parts are prototypes, the rest being components and tools.

LIUX is a Spanish brand dedicated to evolving the electric vehicle industry through innovative technologies. One of its most representative results is the LIUX Animal, an electric car 3D printed from recyclable or plant materials. Using additive manufacturing technology, LIUX managed to reduce energy consumption by 70%, body weight, shortened production cycles and carbon dioxide emissions.

UNITED KINGDOM.

When talking about the British automotive industry, people will naturally think of Bentley, Jaguar, Rolls-Royce and other brands that produce high-end luxury cars. These manufacturers are also gradually introducing additive manufacturing technology into their production processes, and well-known automotive brands including Bentley, McLaren and MINI are all using 3D printing technology.

One of the ways these brands are using 3D printing is to customize one-of-a-kind sports cars, which is very consistent with the luxury and luxury image of the British automotive industry. Aston Martin tried polymer extrusion technology for the first time as early as 2021 and recently used metal 3D printing technology to develop the new Valiant, which is a track-legal model. Rolls-Royce is not only famous for its metal additive manufacturing in the aerospace field, but also applies metal and polymer 3D printing to its automotive fields. The most recent representative model is the specially customized Black Rose, which contains a 3D printed lower intake. collector.

Of course, the British automaker doesn’t just use additive manufacturing to personalize its vehicles. Bentley has established its own 3D printing center at its Crewe factory, which produced more than 15,000 parts in 2021. The factory will be further expanded in 2022. The range of applications for 3D printing includes prototyping, customization and small batch production. Similarly, Jaguar also became one of the first companies to introduce an additive manufacturing center in 2020, with the Jaguar XE SV Project 8 becoming one of the first cars to feature 3D printed final parts.

McLaren has partnered with Stratasys to introduce additive manufacturing technology to its racing division and recently signed a partnership agreement with Divergent Technologies to integrate additive manufacturing into the production of its next-generation supercar. Reducing vehicle weight and improving dynamic performance are key factors for McLaren’s adoption of additive manufacturing, demonstrating the British automaker’s extensive use of additive manufacturing.

Italy

Major Italian automakers, including brands such as Ferrari, Maserati, Lamborghini, Pagani, Dallara, Fiat and Alfa Romeo, have adopted or experimented with 3D printing technology to manufacture prototypes and final parts. Additive manufacturing technology allows these manufacturers to improve the efficiency and performance of vehicle production. Companies located in the Italian Automobile Valley are characterized by luxury and customization, and customization is one of the main advantages of additive manufacturing.

Ferrari, for example, has been experimenting with metal 3D printing, using DMLS technology to create higher-performance metal parts and aerodynamic components for its vehicles, including F1 racing cars. Maserati’s MCXtrema uses a 3D printed body design and custom vehicle seats using PolyJet technology.

Lamborghini is also very representative in additive manufacturing, and its 3D printed model Sián has attracted wide attention. This choice is explained not only by the fact that 3D printing allows for production in small batches, but also because it can offer a wide range of interior and exterior customization options. Components including air inlets, connectors, brackets and housings are all 3D printed using SLS polymer technology. There are also emerging companies in the Italian automotive industry, such as XEV, which has developed Yoyo, a small electric car with a 3D printed body designed to provide a more dynamic and sustainable means of travel.

Suede

Sweden, home to well-known brands such as Volvo and Koenigsegg, has introduced 3D printing technology into its manufacturing process in recent years. As a major player in the global automotive market, Volvo uses innovative cold spray technology developed by Titomic, which can deposit special metals on the surface without melting it. Volvo Trucks uses this technology particularly during the maintenance, repair and overhaul of heavy vehicle engines.

Koenigsegg, known for its hybrid supercars, has used 3D printing technology extensively in its production, using FDM and resin printers to make thousands of parts. Its founder and CEO Christian von Koenigsegg said they make their own resin for the 3D printing process and make electronic controller housings, spray nozzles, heat sinks and other high-temperature components. Koenigsegg also uses 3DPrinterOS software to improve the production process and achieve rapid prototyping and testing of components through 3D printing, thereby improving production efficiency and reducing costs.

Czech Republic

Skoda Auto, a member of the Volkswagen Group and the largest employer in the Czech Republic, has been using 3D printing technology for many years to develop new models, produce prototypes, manufacture spare parts and test materials in series. In the main factory in Mladá Boleslav, the production and logistics department houses a 3D printing farm equipped with around fifty printers, including Prusa models. These machines can produce complex parts quickly and precisely.

Thanks to this successful initiative, Skoda is expanding plastic 3D printing to other factories. Additive manufacturing allows Skoda’s technical team to develop prototypes and spare parts in-house, reducing reliance on external components, resulting in faster production speeds, increased efficiency and reduced costs. Michael Oeljeklaus, head of production and logistics at Skoda, added: “We use 3D printing technology to manufacture parts and tools faster, more efficiently and at lower cost, taking full advantage of the Industry 4.0. »

Austria

Red Bull Racing is actively integrating additive manufacturing technology into its Formula 1 cars to reduce weight and optimize performance. As part of an 18-year collaboration with partner Hexagon Manufacturing Intelligence, Red Bull Racing has reduced manufacturing error rates by 50% using 3D printing.

Before actual production, the team uses digital twins and simulation technology to test the race cars. The design process uses CAD software, while the manufacturing stage relies primarily on stereolithography (SLA) technology. This allows prototypes and parts to be created quickly, speeding up development cycles and improving reliability.

Red Bull Racing’s director of engineering said: “Without 3D printing, we cannot remain competitive on the track. Additionally, 3D printing is also used to manufacture drones to evaluate on-track performance, giving the team a strategic advantage by quickly introducing innovation. » . Artificial intelligence technology also helps optimize the design process to adapt the car to different climatic conditions.

In fact, while European automakers are adopting 3D printing technology, Chinese automakers are not far behind and are actively exploring the application of additive manufacturing in the automotive field. Industry giants such as SAIC, Geely, BYD, and NIO have all completed 3D printing-related projects to varying degrees.

The global automotive industry is undergoing transformation and 3D printing technology is continually affecting all aspects of automotive design, production and service with its unique benefits. Whether in Europe or China, more and more automakers are accelerating the deployment of 3D printing, pushing the industry towards a more efficient, greener and more personalized future.