On October 30, 2024, the Resource Library learned that recently, Dr. Jeong Min Park’s team from Korea Institute of Materials Science (KIMS) cooperated with Gyeongsang National University and University of Science and Technology. Pohang Technologies (POSTECH) and successfully developed metal 3D printing alloys. This alloy is available fromExtremely cold conditions of -196°CIt demonstrates excellent performance in certain conditions and provides new solutions for future applications in space exploration and extreme environments.

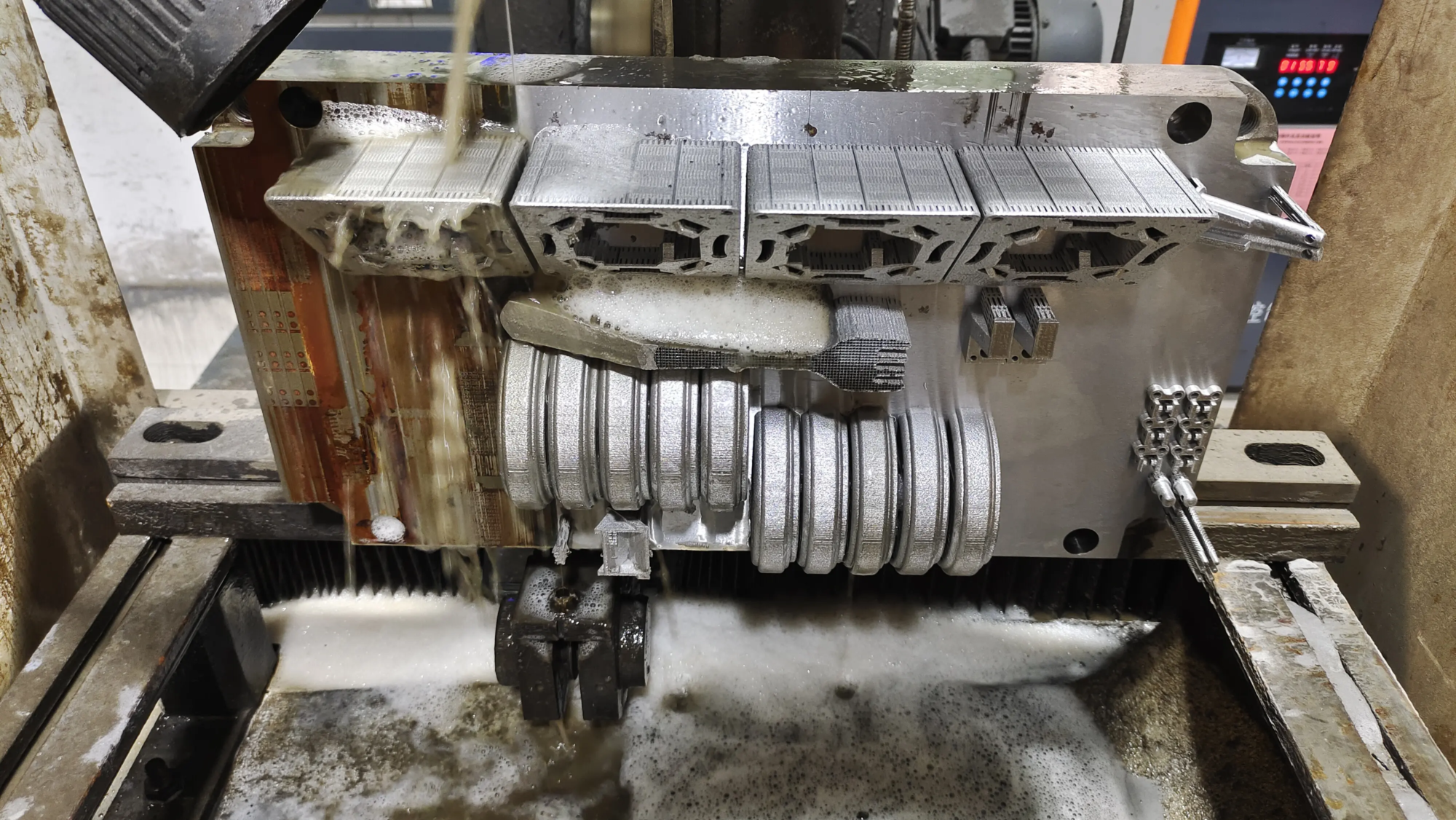

The research team added a small amount of the element carbon to the high-entropy alloy CoCrFeMnNi. This adjustment significantly improved the alloy’s low temperature performance. The alloy is processed using laser powder bed fusion (LPBF) technology, which allows the nanoscale carbides to be evenly distributed at the boundaries of the cellular structure, maximizing the reinforcing effect of the carbon on the material. Experimental results show that this alloy exhibits excellent performance in extremely low temperature environments.Tensile strength and ductilityThan the traditional carbon-free versionIncreased by over 140%。

It is particularly worth mentioning that,In an environment of 77K (-196°C)the elongation of the alloy (the ability of the material to deform before breaking) isTwice as much as at normal temperature 298K. This advancement not only solves the problem of insufficient toughness of traditional metal 3D printing materials under low temperature conditions, but also provides new ideas for alloy design in additive manufacturing (AM) technology, enabling it to produce products with excellent load capacity in extreme conditions. terms. high-performance products.

This 3D printing metal alloy has broad application prospects, especially for complex components such as fuel injectors and turbine nozzles of space rockets. Its excellent low temperature performance and mechanical strength not only improve the reliability of key components in space and other extreme environments, but also significantly extend their service life. At the same time, this technology overcomes the toughness bottleneck of existing 3D printing alloys in low-temperature environments, providing a better choice of materials for future spacecraft and space exploration equipment. deep space.

The research was funded by KIMS Foundational Projects, including support for two projects: “Development of Additive Manufacturing Technology for Ultra-Hard Heterogeneous Materials with Complex Designs” and “Development of High-Performance Materials and Processes for metal 3D printing. The research results were published in the internationally renowned academic journal “Additive Manufacturing”. In the future, the research team plans to further improve the commercialization potential of this technology and conduct more verification work to ensure its stable application in different extreme environments.